Method and device for carrying out partitioning catalytic cracking on coking waxen oil

A technology for coking wax oil and catalytic cracking, which is applied in the field of catalytic conversion of petroleum hydrocarbons, can solve problems such as the influence of catalytic cracking process, achieves excellent product distribution, solves difficult processing, and improves liquid yield.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

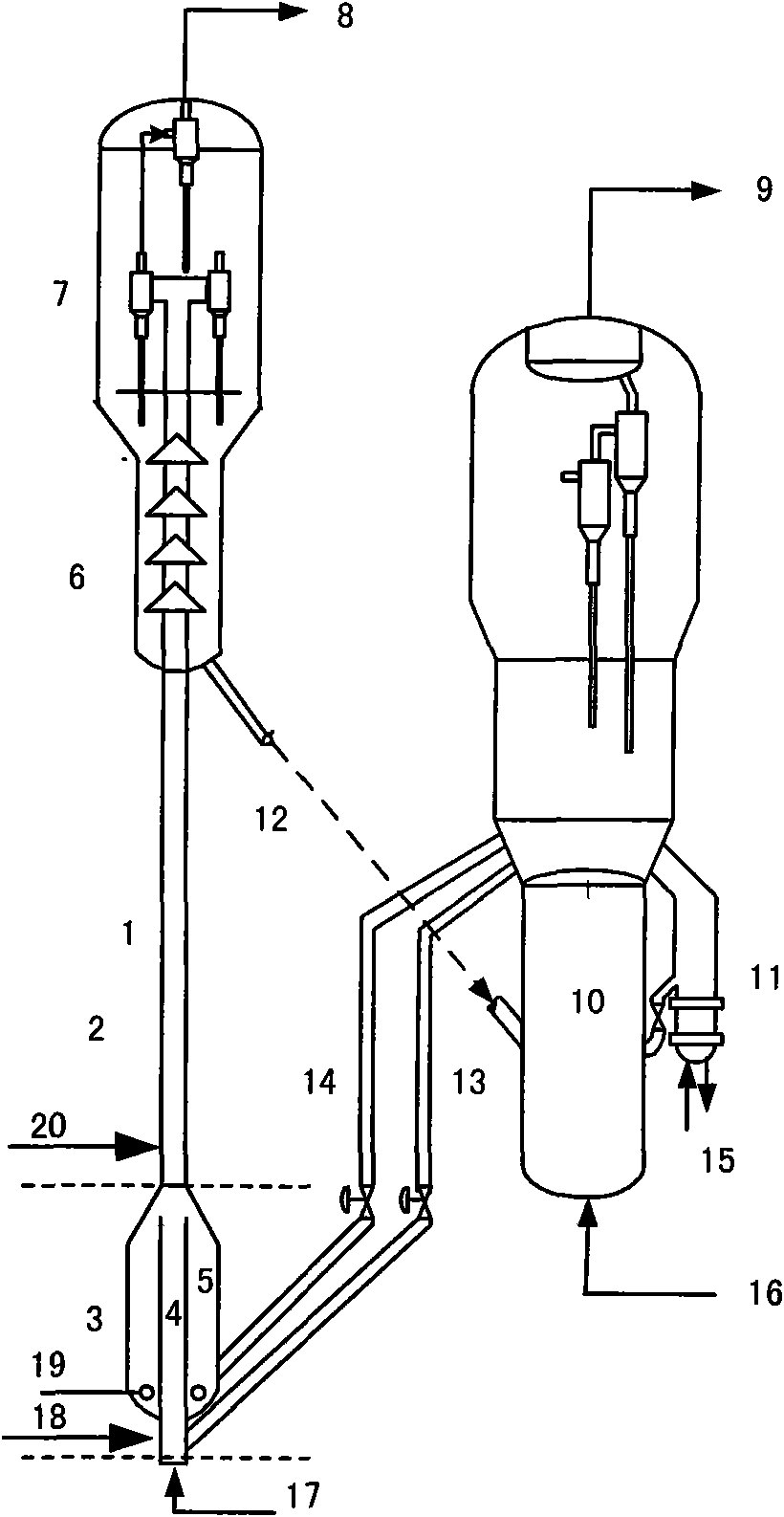

[0040] Embodiment 1 of the method and device for processing coker wax oil proposed by the present invention is as figure 1 shown.

[0041] The method is as follows: at first, the riser reactor 1 of the conventional catalytic cracking unit is divided into upper and lower reaction zones, the upper reaction zone is 2, the lower reaction zone is 3, and the lower reaction zone 3 is divided by an inner pipe 4 and an outer pipe 5. It is two independent areas inside and outside, and the ratio of the cross-sectional area of the inner pipe to the cross-sectional area of the annulus is 1:1-10. The inner pipe 4 is connected to the inclined regeneration pipe 13, and the outer pipe 5 is connected to the inclined regeneration pipe 14. The length of the riser reactor including the upper and lower reaction zones is called the effective length of the riser reactor. The length of the lower reaction zone 3 is 5% to 50% of the effective length of the riser reactor, preferably 10% to 30%. On t...

Embodiment 2

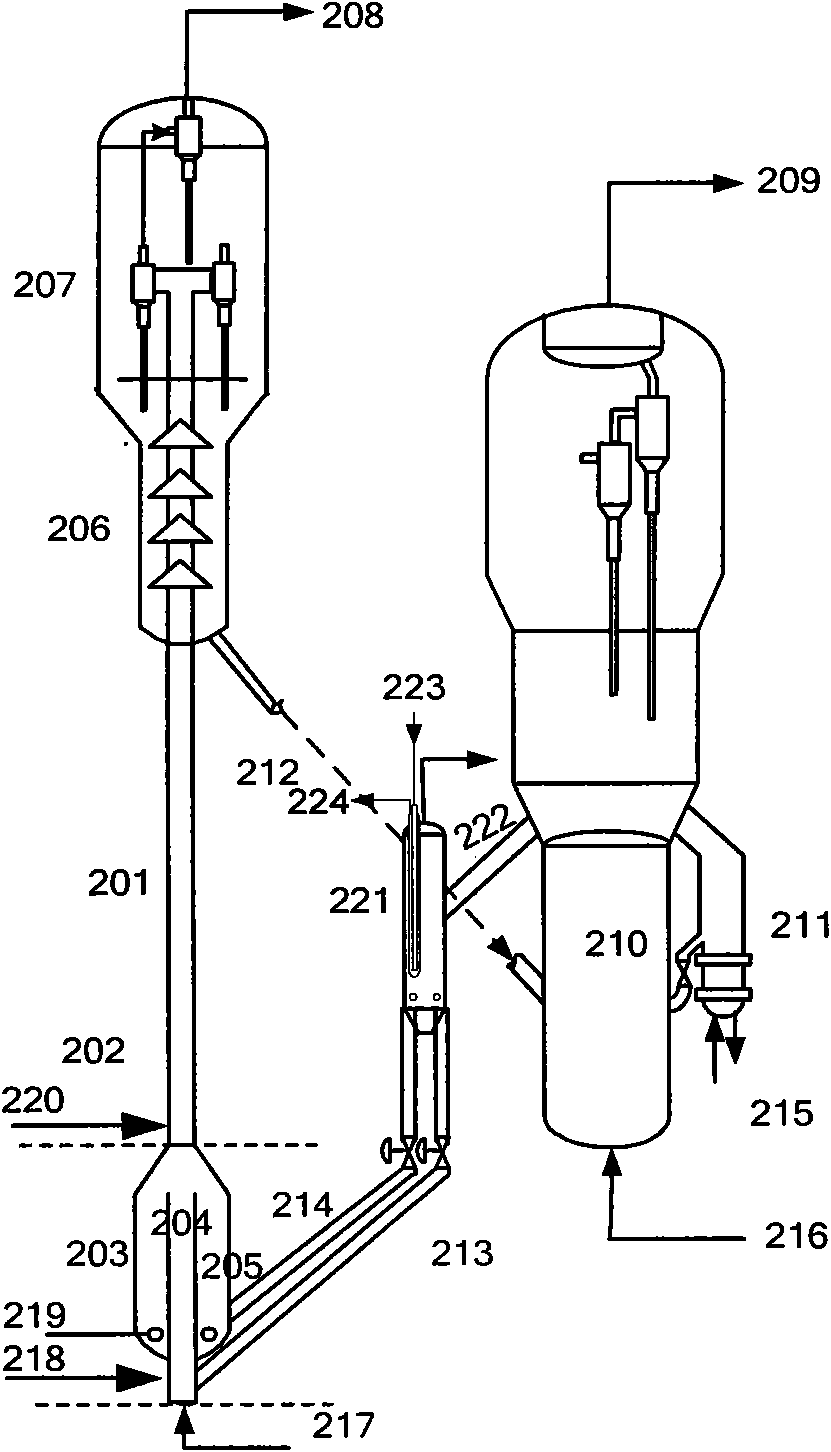

[0047] figure 2 Example 2 showing the method and apparatus for processing coker gas oil according to the present invention.

[0048] The method is firstly dividing the riser reactor 201 of the conventional catalytic cracking unit into upper and lower reaction zones, the upper reaction zone is 202, the lower reaction zone is 203, and the lower reaction zone 203 is divided by an inner pipe 204 and an outer pipe 205. It is two independent areas inside and outside, and the ratio of the cross-sectional area of the inner pipe to the cross-sectional area of the annulus is 1:1-10. The inner pipe 204 is connected to the regeneration inclined pipe 213, and the outer pipe 205 is connected to the regeneration inclined pipe 214. The length of the riser reactor including the upper and lower reaction zones is called the effective length of the riser reactor. The length of the lower reaction zone 203 is 5 to 50% of the effective length of the riser reactor, preferably 10 to 30%. On this...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com