Method for producing high-purity pure iron

A high-purity, pure iron technology, applied in the manufacture of converters, etc., can solve the problems of popularization of production restrictions, low purity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below by way of examples.

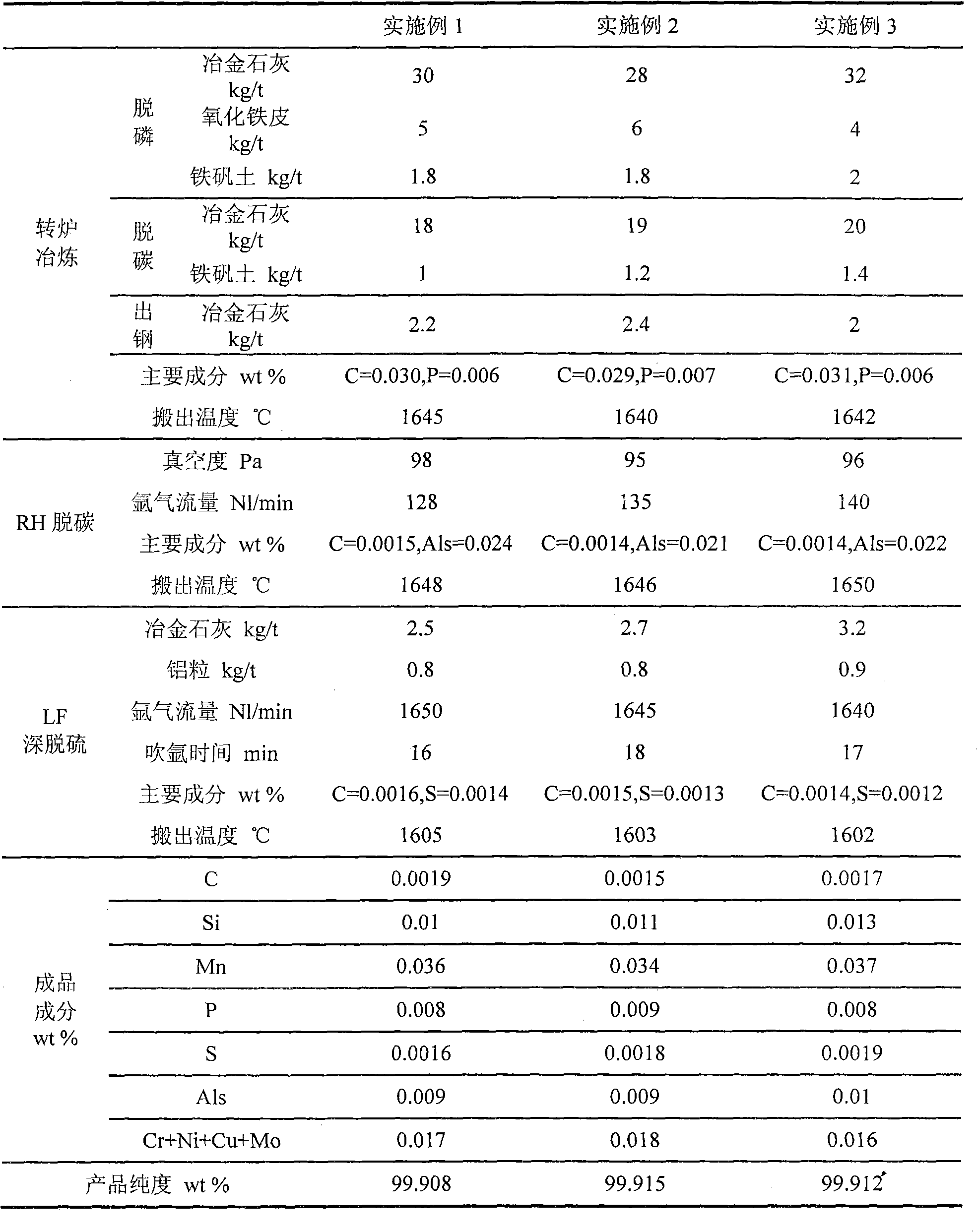

[0018] The production method of the embodiment of the present invention is shown in Table 1.

[0019] Table 1 Production method of the embodiment of the present invention

[0020]

[0021] In the embodiment of the present invention, the following stations are controlled as follows: the molten iron pretreatment requires to ensure that the sulfur content of the molten iron entering the converter is between 0.015% and 0.002%. Remove more than 95% of the oxidized slag after tapping from the converter, and add small particles of high-efficiency active metallurgical lime 4kg / t after removing the slag. The deep desulfurizer added before LF enters the station is a mixture of activated calcium oxide: passivated aluminum powder = 6:4, the addition amount is 4kg / t, and then the argon flow is stirred at 800NL / min to completely melt the deep desulfurizer. When LF is moved out, add covering agent to keep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com