Method for preparing cobalt-doped improved beta-bismuth oxide photocatalyst

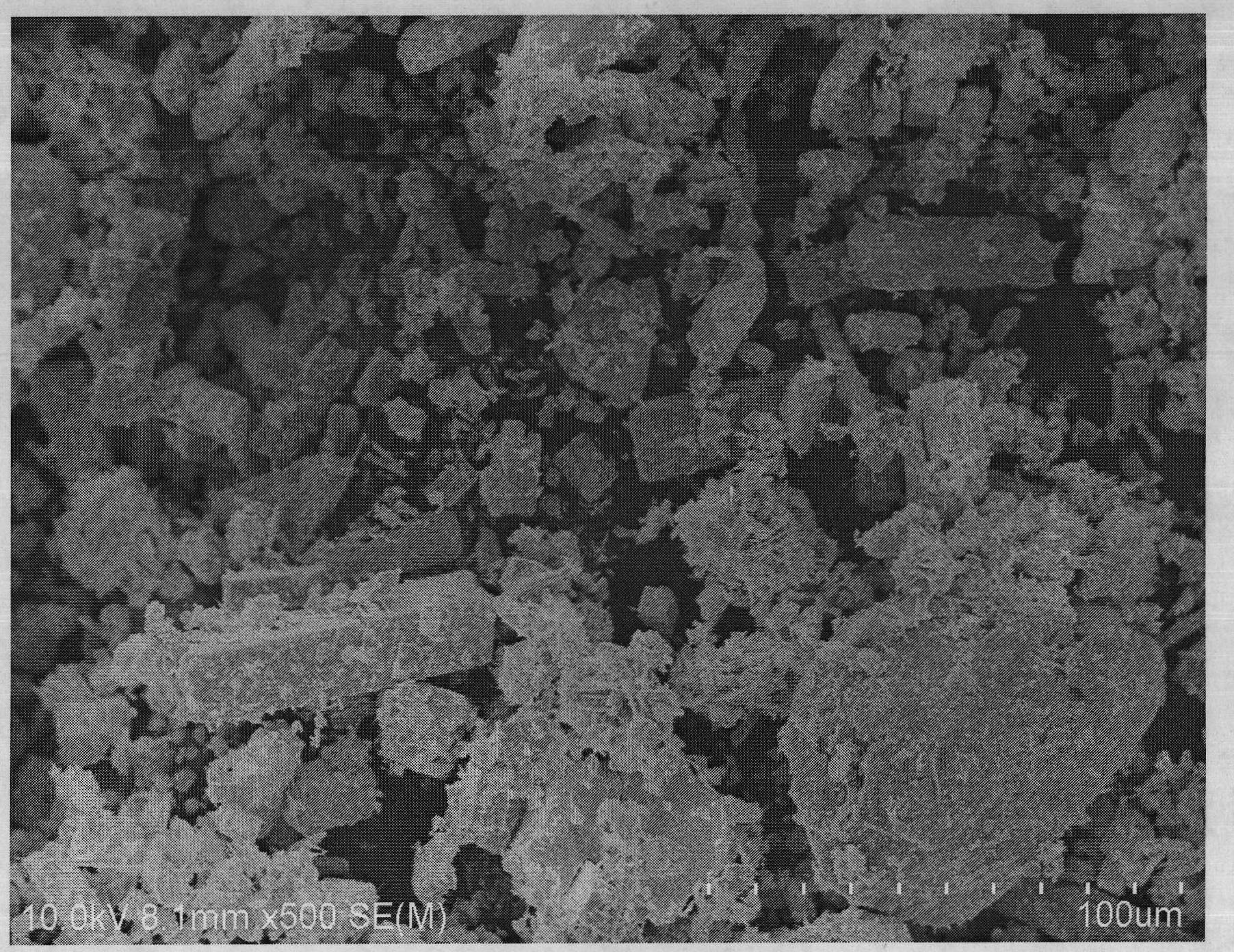

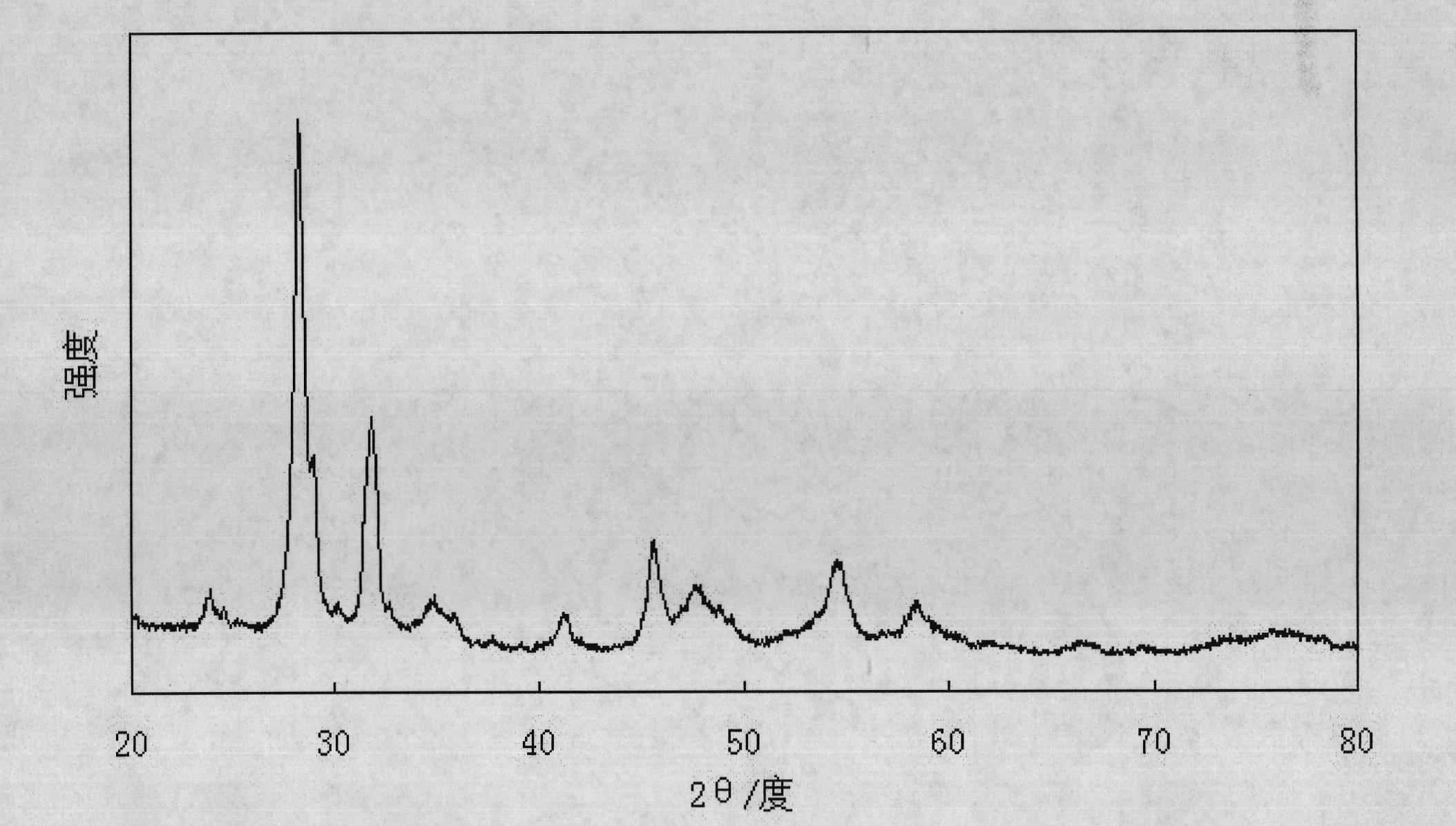

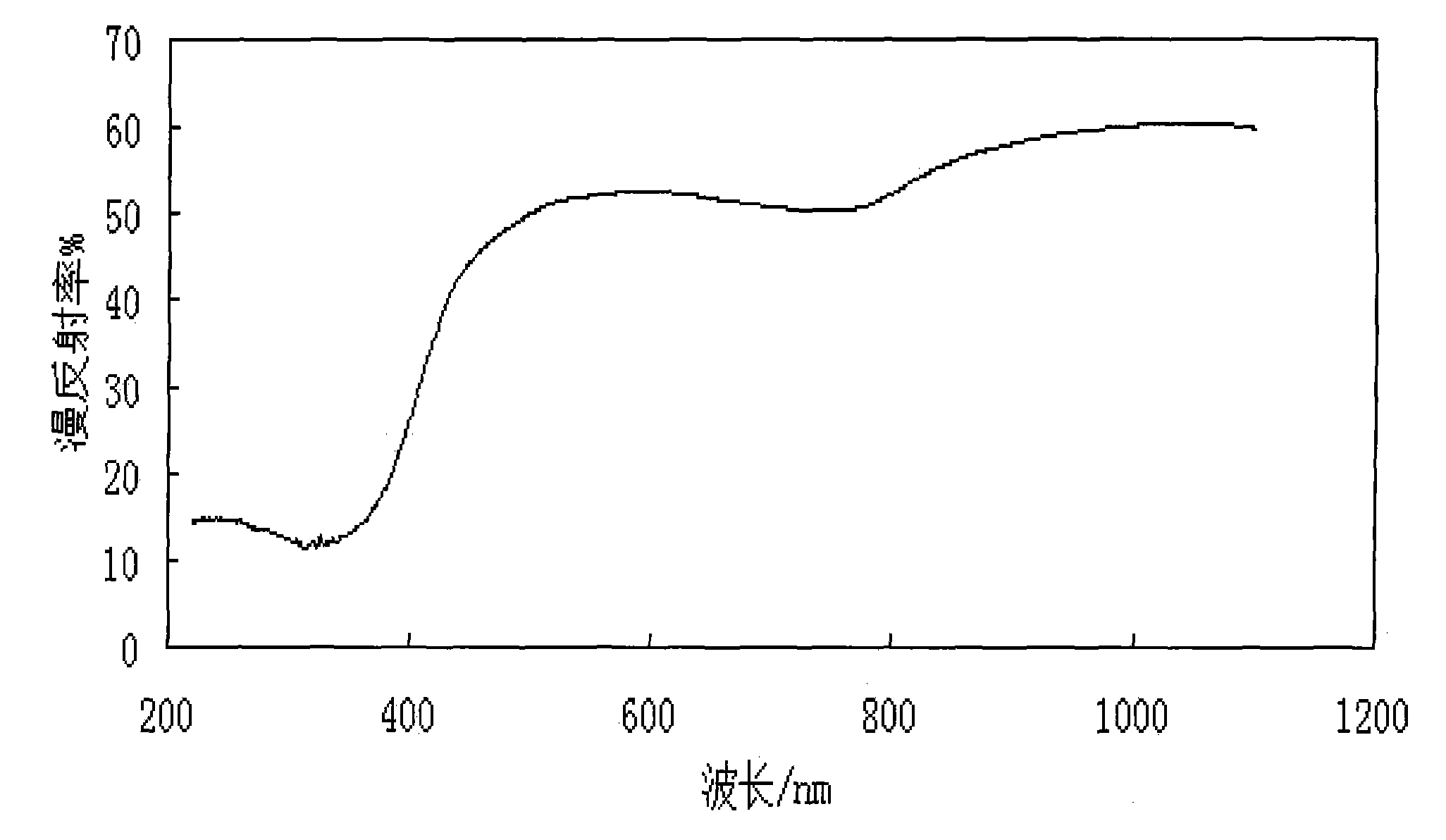

A technology of photocatalyst and bismuth oxide, which is applied in the field of environmental science and engineering to achieve the effects of high catalytic activity, loose and porous structure, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Take by weighing 9.28 grams of Pluronic P-123 block copolymer surfactant and place it in a beaker, add 100 milliliters of nitric acid (HNO 3 ) solution, stirred by a magnetic stirrer, after the Pluronic P-123 is completely dissolved in nitric acid to form a colorless and transparent solution, add 24 grams of bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O), continue to stir. After the solution is clarified, add 0.87 gram of cobalt nitrate (Co(NO 3 ) 2 ·6H 2(0), continue to stir until cobalt nitrate dissolves completely, and this moment, solution exists with rose red homogeneous sol form. While continuing to stir, the sol was aged at room temperature for about 3 hours to obtain a rose-red precursor solution; the solution was transferred to a stainless steel autoclave lined with polytetrafluoroethylene, and the autoclave was sealed Put it in a vacuum drying oven at 150°C for 24 hours to crystallize; take out the autoclave to cool to room temperature, then take out...

Embodiment 2

[0025] Preparation of precursor step is the same as in Example 1, wherein Pluronic P-123: 9.28g; Nitric acid (2 mol / liter): 100 milliliters; Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O): 24g; cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O): 0.87 g; calcination temperature 550°C. Recorded as sample 2#.

Embodiment 3

[0027] Precursor preparation step is the same as embodiment 1, wherein Pluronic P-123: 6.96g; Nitric acid (2 mol / liter): 100 milliliters; Bismuth nitrate pentahydrate (Bi(NO 3 ) 3 ·5H 2 O): 20.37g; cobalt nitrate (Co(NO 3 ) 2 ·6H 2 O): 0.87 g; calcination temperature 500°C. Recorded as sample 3#.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com