Method and system for deep purification of drinking water by adopting oxidation-resistant film

A deep purification and oxidation-resistant technology, applied in chemical instruments and methods, oxidized water/sewage treatment, water/sewage multi-stage treatment, etc., can solve pollution and other problems, achieve the effects of reducing pollution, improving efficiency, and facilitating maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

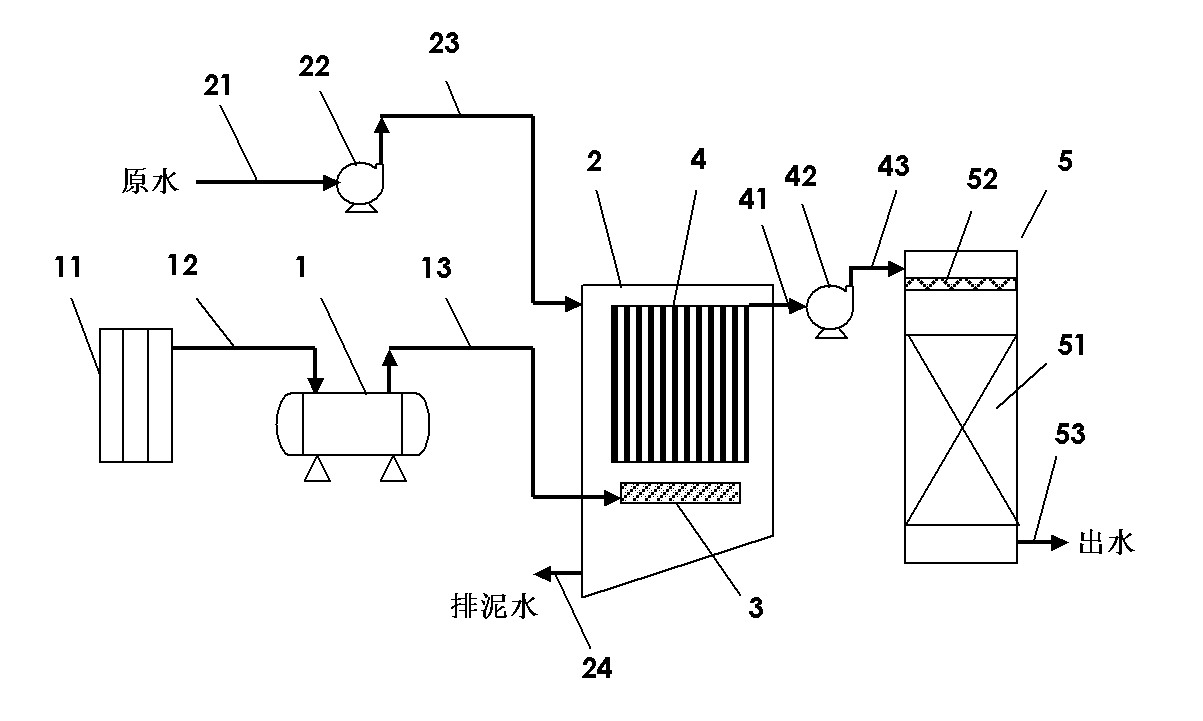

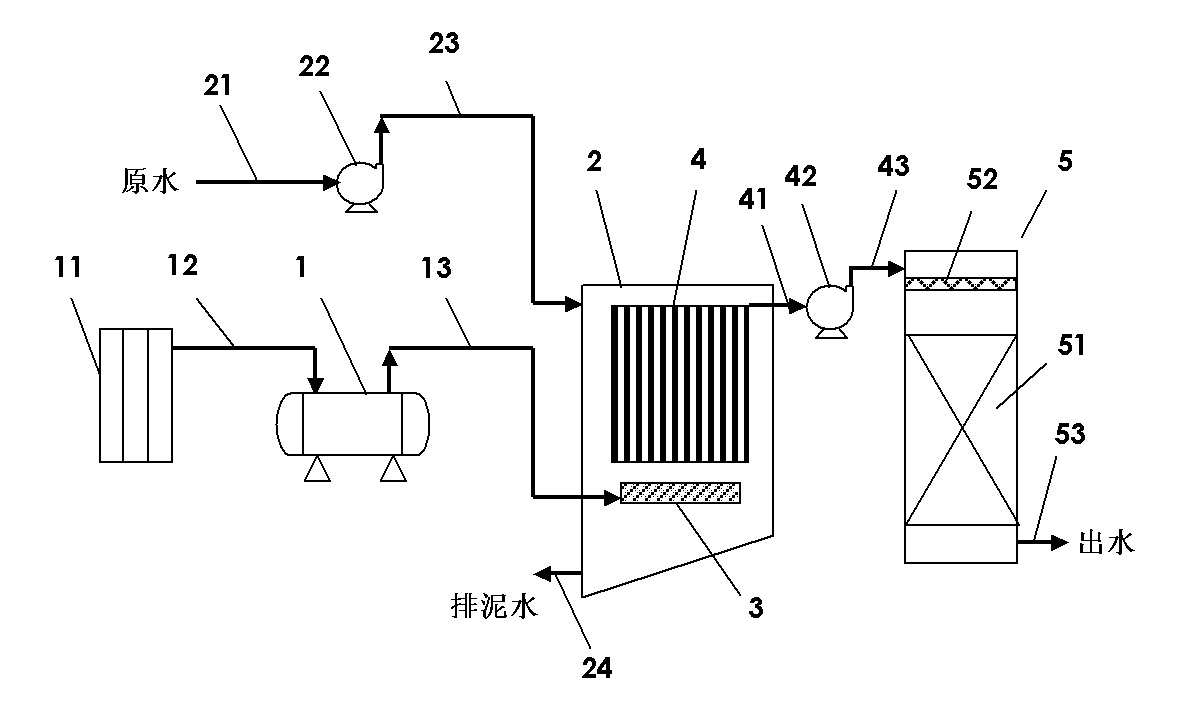

[0022] The present invention will be further explained below in conjunction with the drawings and specific tests.

[0023] figure 1 The shown system mainly includes: an ozone generator 1, a contact tank 2, a microporous aerator 3 and an oxidation-resistant membrane filter assembly 4 arranged in the contact tank 2, and a granular activated carbon filter bed 5, etc.

[0024] The ozone generator 1 includes an air source 11, an air inlet pipe 12 and an air outlet pipe 13. The air source 11 adopts dust-removed and dried air or pure oxygen. The pressure of the air source is 0.04-0.1MPa. After high-voltage discharge, ozone-containing gas is generated. Adjust the gas volume and the discharge power of the ozone generator, and the ozone concentration in the outgas can reach 4%-16%. The ozone generator can directly use the existing stereotyped products on the market, but the choice of gas source depends on the level of ammonia nitrogen concentration; when the ammonia nitrogen concentration i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com