Diaphragm for full-vanadium ionic liquid flow battery, preparation method and battery comprising diaphragm

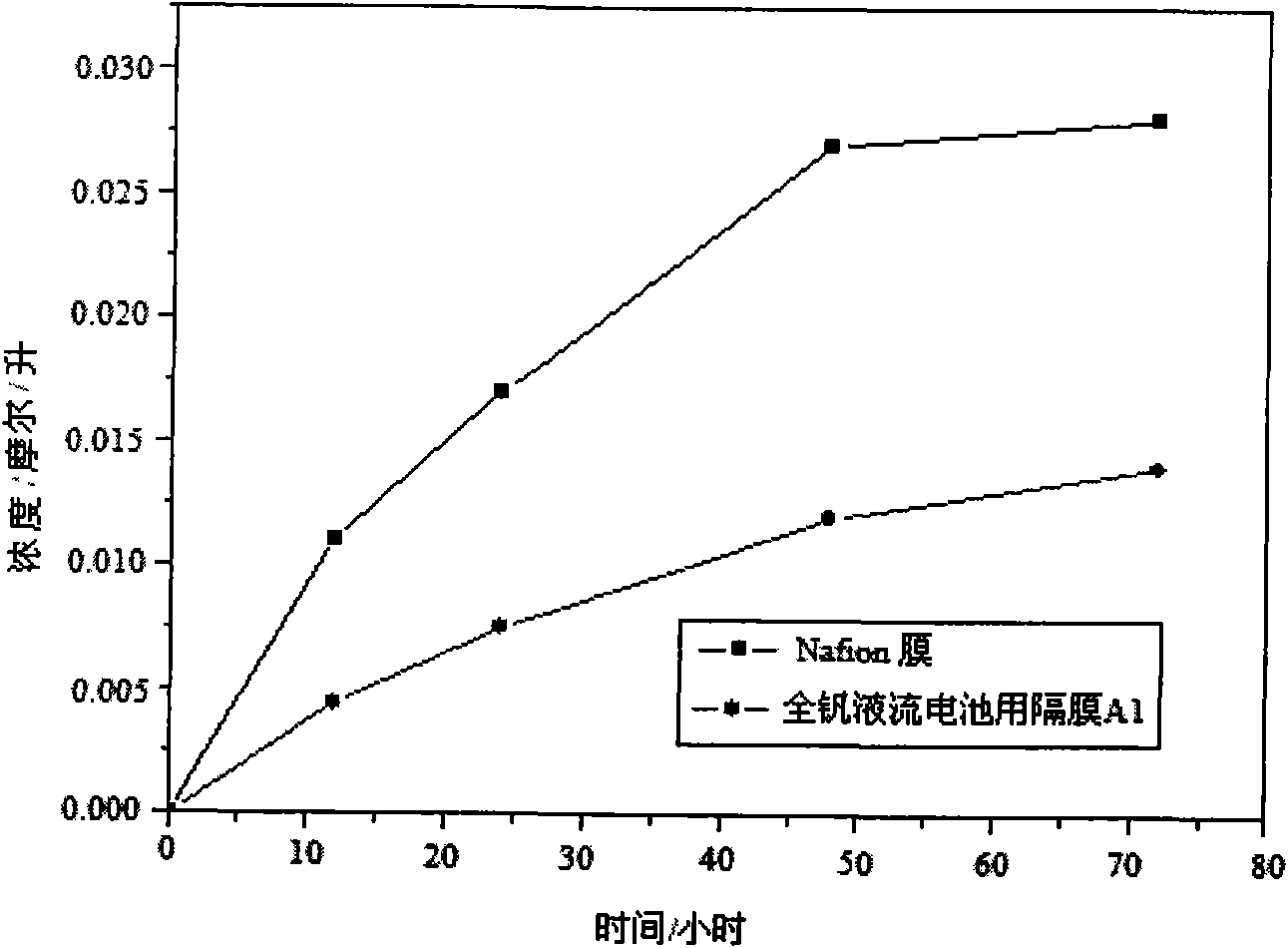

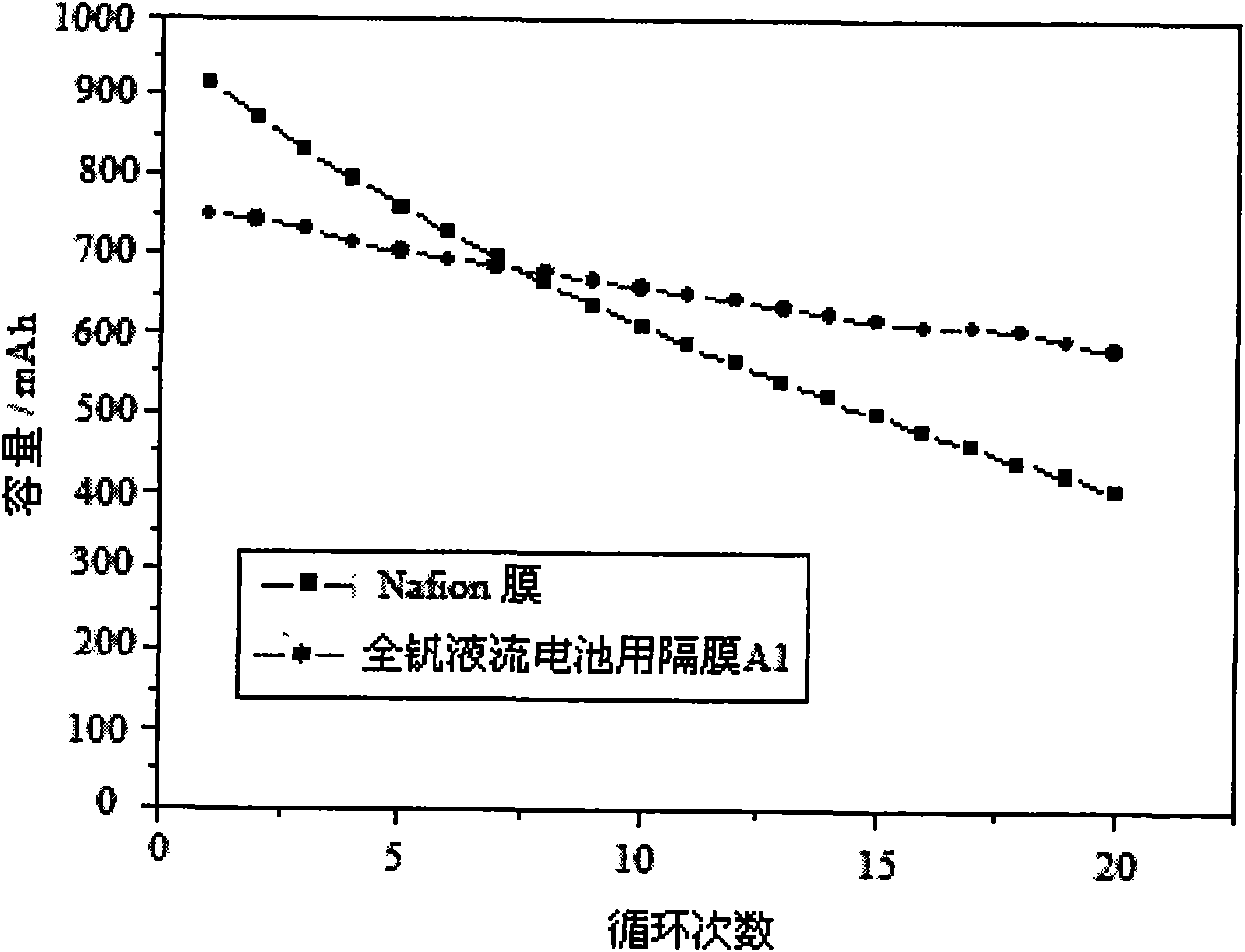

A liquid flow battery and vanadium ion technology, which is applied to fuel cell components, fuel cells, secondary batteries, etc., can solve the problem of large vanadium ion permeability and water mobility, low vanadium ion permeability and water mobility, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The separator for the all-vanadium ion flow battery prepared by the method provided by the invention can be directly used in the production of the all-vanadium ion flow battery. However, usually, the separator prepared by the method provided by the invention needs to be stored for a period of time. Time can be used in subsequent production. For the convenience of storage, it is preferable to include a drying step at 70-90° C. after the above preparation method.

[0033] In addition, the present invention also provides an all-vanadium ion flow battery, the all-vanadium ion flow battery includes two electrolyte pools and a diaphragm, and the electrolyte pools hold the anode vanadium ion electrolyte and the cathode vanadium ion respectively Electrolyte, the diaphragm separates the two electrolyte pools, wherein the diaphragm is the diaphragm for the all-vanadium ion flow battery provided by the present invention. In the present invention, the anolyte and catholyte are not ...

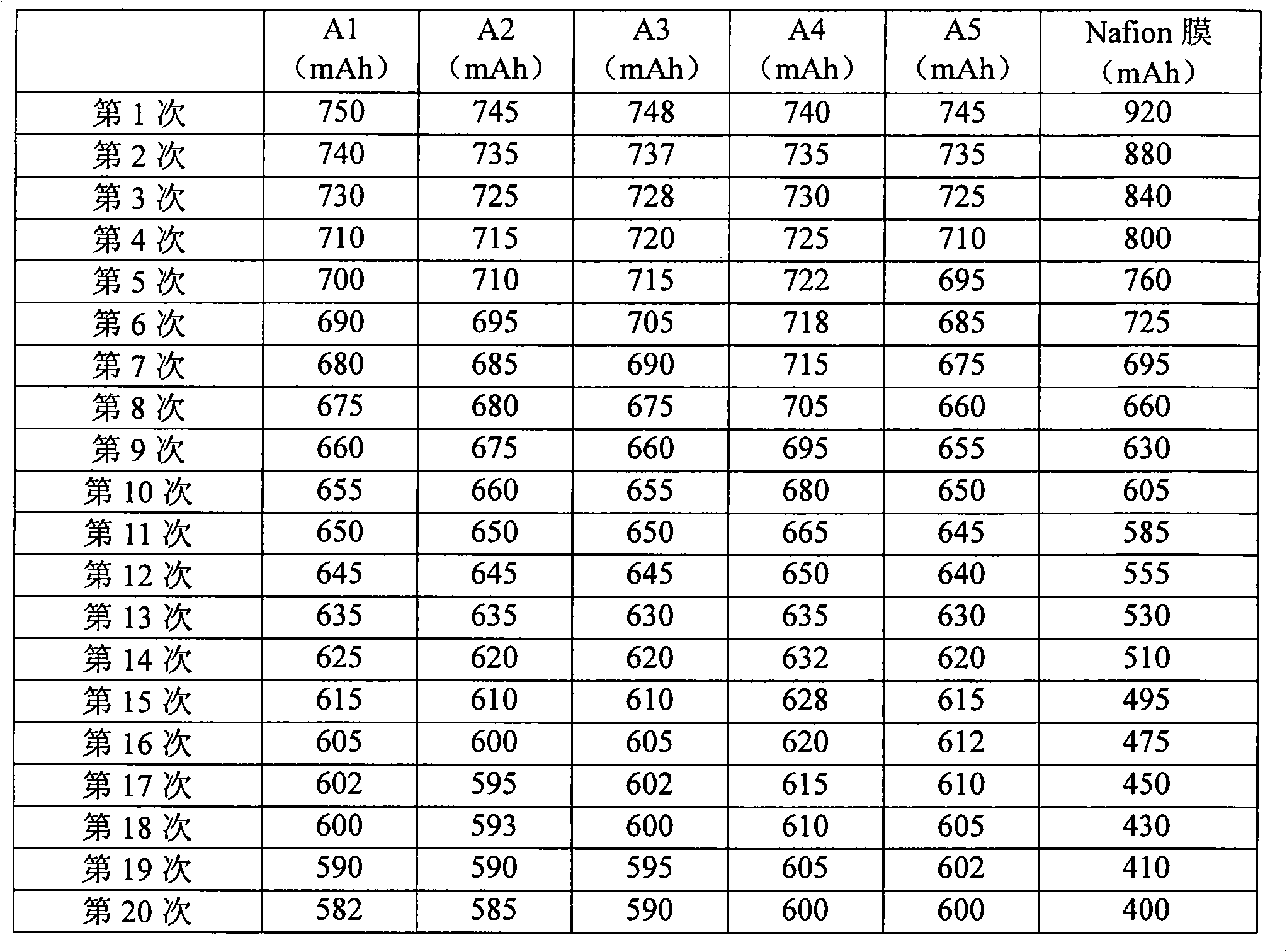

Embodiment 1

[0037] This example is used to illustrate the separator for an all-vanadium ion flow battery provided by the present invention and its preparation method.

[0038] Select a polyaniline homogeneous membrane with a porosity of 50% (the degree of polymerization is 1000, the pore diameter is 160 nanometers, and the ion exchange capacity is 0.4 mmol H) with a size of 10 cm × 10 cm × 0.3 mm. + / g, thickness is 0.25mm), and make it successively with 4% by weight of H of 400 milliliters 2 o 2 The solution was contacted with 400 ml of 0.3 mol / l dilute sulfuric acid solution for 1.5 hours and then with 400 ml of 99.5% by weight acetone solution at 55° C. for 1 hour. The above-mentioned pretreated porous cationic membrane matrix is contacted with the Nafion solution of 5% by weight at a concentration of 150 milliliters, then dried at 80° C. for 10 minutes, and the porous cationic membrane matrix is contacted with the Nafion solution and the subsequent drying step Repeat for 5 times...

Embodiment 2

[0040] This example is used to illustrate the separator for an all-vanadium ion flow battery provided by the present invention and its preparation method.

[0041] Select a polytetrafluoroethylene homogeneous membrane with a porosity of 60% (the degree of polymerization is 800, the pore diameter is 160 nanometers, and the ion exchange capacity is 0.3 mmol H) with a size of 10 cm × 10 cm × 0.3 mm. + / g, the thickness is 0.2 mm), and make it sequentially with 400 ml of 3% H 2 o 2The solution was contacted with 400 ml of 0.1 mol / l dilute sulfuric acid solution for 3 hours and then with 400 ml of 99.5% by weight acetone solution at 50° C. for 2 hours. The porous cationic membrane matrix through above-mentioned pretreatment is contacted with the Nafion solution of 5% by weight with the concentration of 500 milliliters, dried 15 minutes at 70 ℃ afterwards, and makes described porous cationic membrane matrix contact with Nafion solution and the subsequent drying step Repeat for 4 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com