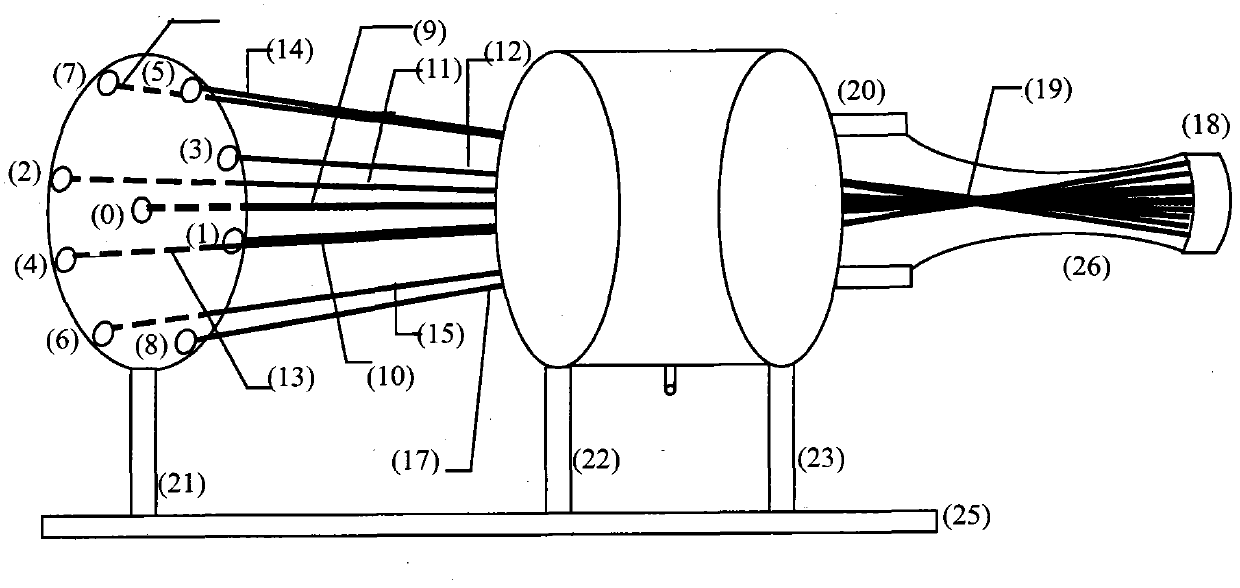

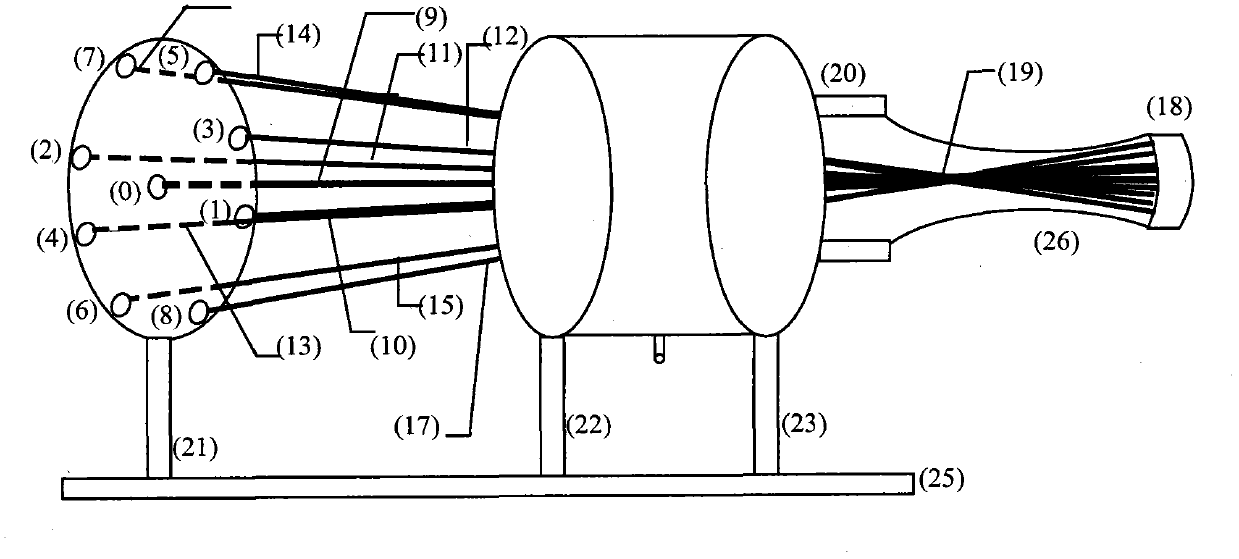

Method and device for constructing multiple CO2 laser system

A technology of laser system and construction method, applied in lasers, laser parts, phonon exciters, etc., can solve the problems of difficulty in improving the output, deformation of the output mirror, and the increase of the output power of the device that affects the performance of the device.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0006] The discharge tubes on the axis and the discharge tubes placed symmetrically on the same conical surface are all inserted into the one-to-one corresponding circular holes of the fixed disc supports 21, 22 and 23, and protrude about 1 cm at 23 toward the output mirror. The gap between the outer edge of each discharge tube and the corresponding round holes of 21 and 22 is about 0.2 mm, and the tube and the disc are fixed elastically. 23 is a disc support made of stainless steel substrate, each corresponding hole is connected with a Kovar tube, each Kovar tube is connected with a glass transition joint, and the discharge tube passes through the inside of the Kovar tube and is connected with the right end of the transition joint. The cathodes of each discharge tube are located at a section of the total reflection mirror and are connected to the high-voltage end of the negative high-voltage power supply; and the anodes have no special requirements for electrode materials, so ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com