Method for controlling laser power supply energy based on DSP (Digital Signal Processor)

A laser power supply and energy control technology, applied in excitation methods/devices, lasers, laser components, etc., can solve the problems of easily damaged laser power supply, power supply burnout, unstable laser energy output, etc., to avoid burning the power supply, avoid straight-through effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

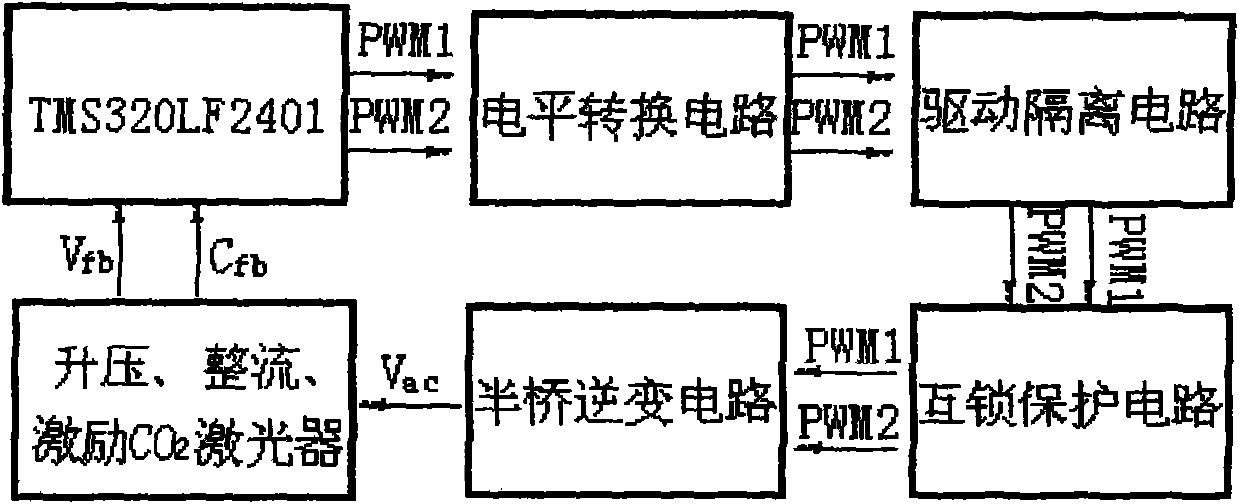

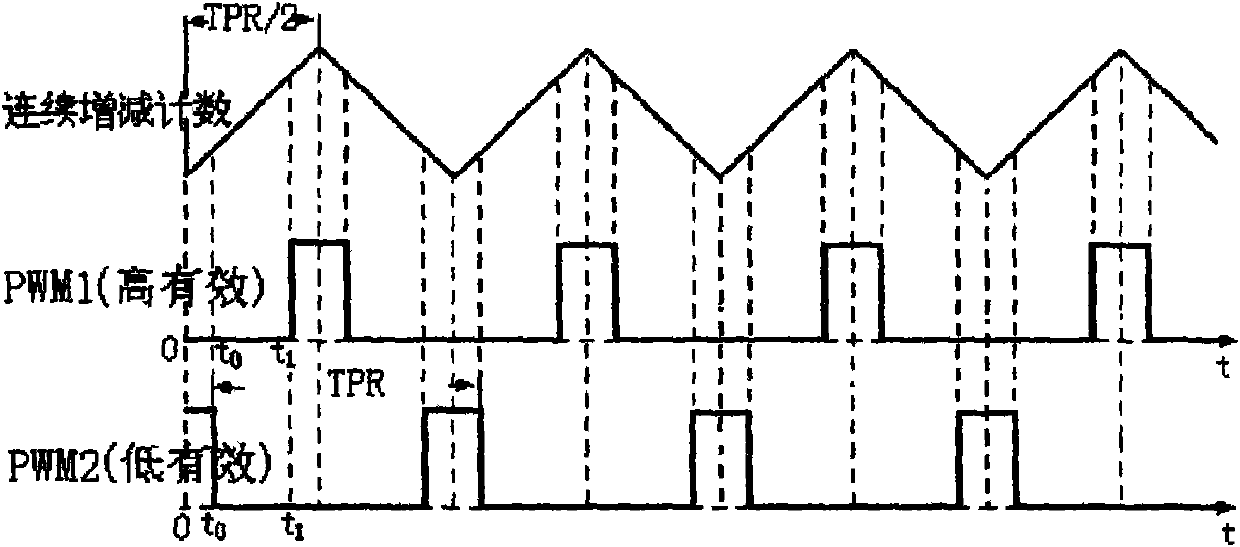

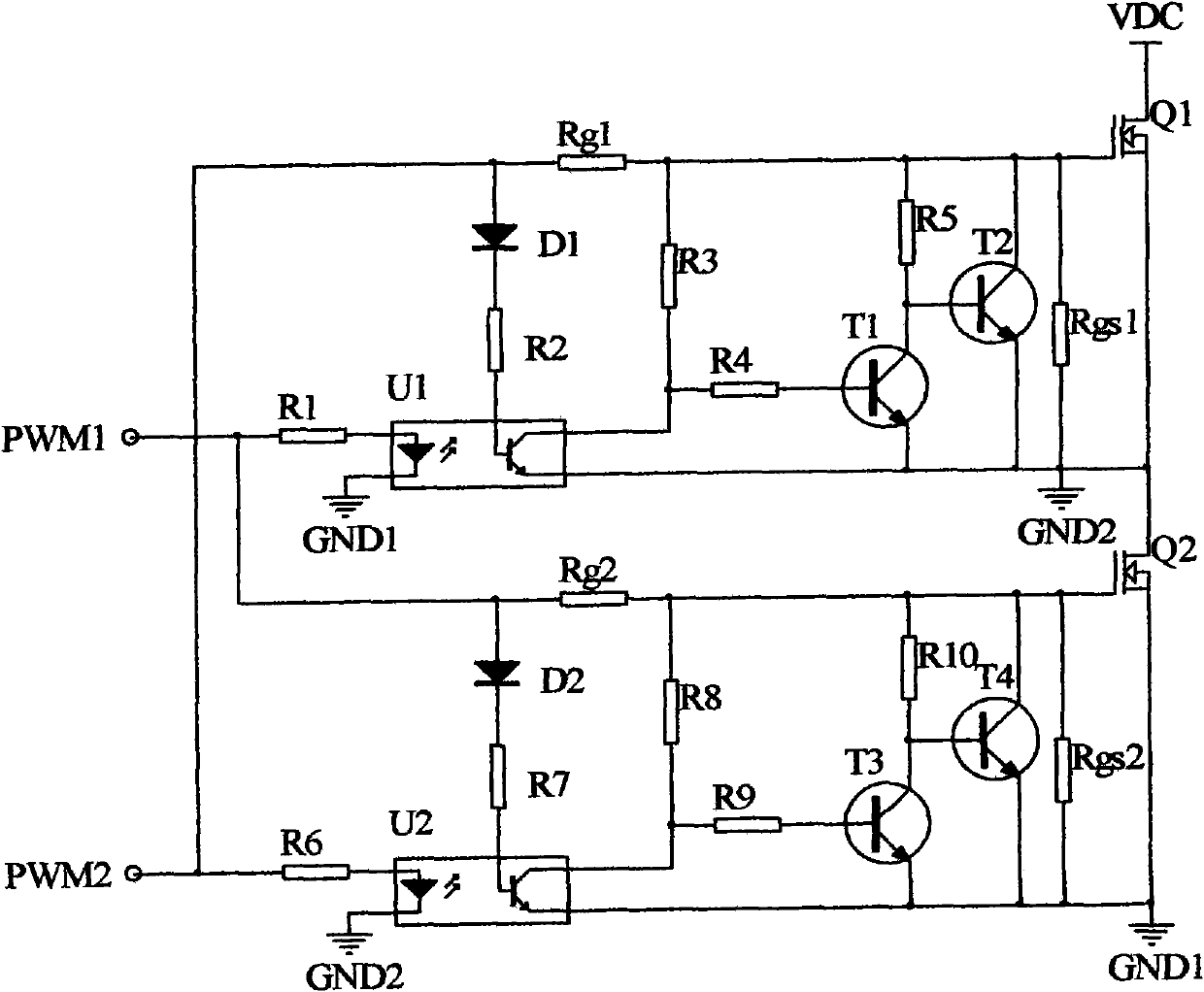

[0018] according to Figure 1-4 As shown, a DSP-based laser power supply energy control method: the on-chip integrated AD of the digital signal processor TMS320LF2401 is used to collect the feedback voltage generated by the high-voltage package and the voltage corresponding to the output current of the CO2 laser tube, according to the principle of constant voltage and constant current feedback control Calculate and update the duty cycle of the PWM wave in real time, and then generate high frequency and high voltage through the half bridge conversion circuit, use the high voltage package to boost the voltage, rectify and excite the CO2 laser tube to output laser. The PWM wave signal generated by the TMS320LF2401 digital signal processor is at TTL level, and then drives the half-bridge conversion circuit through a level conversion circuit, a signal isolation circuit and a signal interlock protection circuit. The method of online identification of abnormal conditions such as no-l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com