Naphtha denitrification adsorbent and preparation method thereof

An adsorbent and naphtha technology, which is applied in the petroleum industry, chemical instruments and methods, and refined hydrocarbon oil, etc., can solve the problems of small adsorption capacity and poor selectivity, and achieve stable adsorption performance, simple preparation method, and adsorption selectivity. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

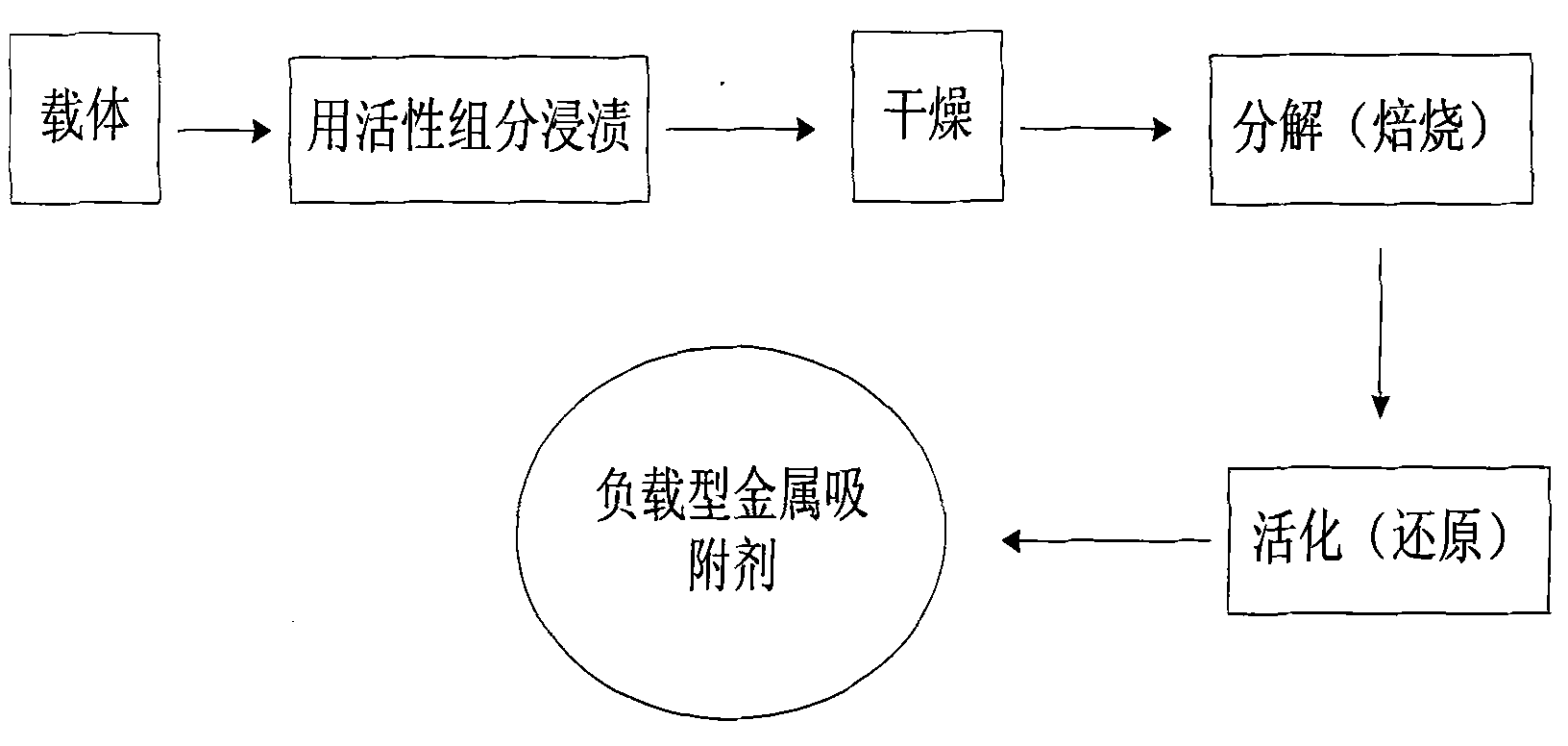

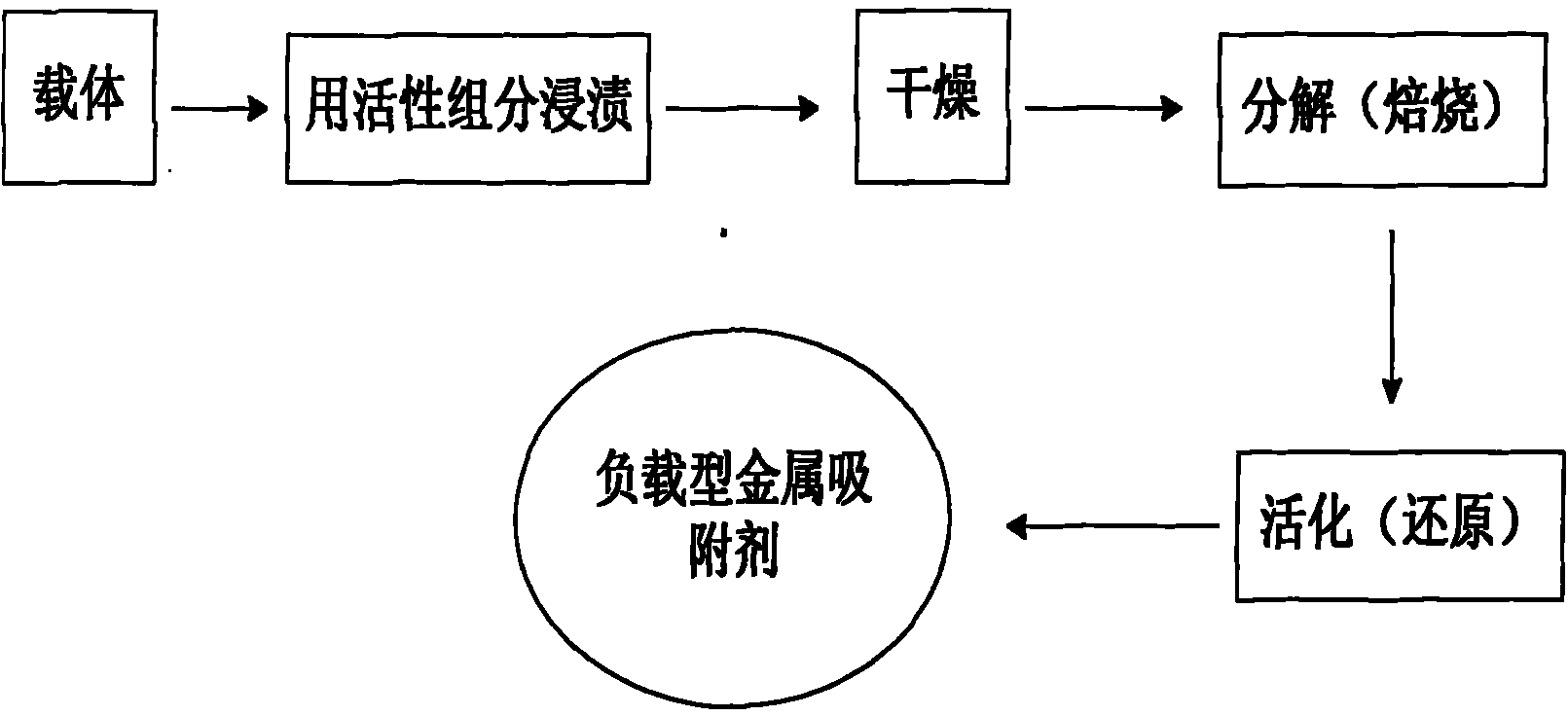

Method used

Image

Examples

Embodiment 1

[0028] (1) Prepare phosphoric acid with a concentration of 1mol / L as the impregnation solution.

[0029] (2) According to the carrier: impregnating solution = 1:4 (mass ratio), 13X molecular sieve packed in the form of fixed bed is added as an adsorption carrier into corresponding volume of phosphoric acid impregnating solution, and impregnated for 24 hours.

[0030] (3) The primary product of the adsorbent was dried in a constant temperature drier for 3 hours, then placed in a box-type resistance furnace, activated at 300°C for 3 hours, and cooled to room temperature to obtain a denitrification adsorbent.

[0031] The prepared granular acid-carrying 13X molecular sieve adsorbent can remove the organic nitrogen in straight-run naphtha of pipeline transportation crude oil. ppm. The initial adsorption removes organic nitrogen in naphtha, and the oil-to-solvent ratio (mass) can reach 190.3. The adsorbent can be reused after being purged with hot nitrogen gas; after being washed ...

Embodiment 2

[0033] (1) Prepare sulfuric acid with a concentration of 1mol / L as the impregnation solution.

[0034] (2) According to the carrier: impregnation solution = 1:5 (mass ratio), activated alumina packed in the form of a fixed bed is added as an adsorption carrier into a corresponding volume of sulfuric acid impregnation solution, and immersed for 17 hours.

[0035] (3) The primary product of the adsorbent was dried in a constant temperature drier for 4 hours, then placed in a box-type resistance furnace, activated at 200°C for 4 hours, and cooled to room temperature to obtain a denitrification adsorbent.

[0036] The adsorption strength of the obtained adsorbent fully meets the preparation requirements of the present invention through inspection, and the adsorbent can be reused after being purged with hot nitrogen; after being washed with sulfuric acid solvent, the adsorption capacity can be restored to more than 95% of the desorption capacity of the fresh adsorbent.

Embodiment 3

[0038] (1) Prepare nitric acid with a concentration of 1.5mol / L as the dipping solution.

[0039] (2) According to carrier: impregnating liquid = 1:2 (mass ratio), activated carbon packed in the form of fixed bed is added as an adsorption carrier into corresponding volume of sulfuric acid impregnating liquid, and impregnated for 10 hours.

[0040] (3) Put the primary product of the adsorbent in a constant temperature dryer to dry for 2 hours, put it into a box-type resistance furnace, activate it at 200°C for 2 hours, and cool it down to room temperature to obtain the denitrification adsorbent.

[0041] The adsorption strength of the obtained adsorbent fully meets the preparation requirements of the present invention through inspection, and the adsorbent can be reused after being purged with hot nitrogen; after being washed with nitric acid solvent, the adsorption capacity can be restored to more than 95% of the desorption capacity of the fresh adsorbent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com