Manufacturing method of beta-cyclodextrin matrix solid-phase micro-extraction head

A technology of matrix solid phase and cyclodextrin, applied in chemical instruments and methods, material separation, instruments, etc., can solve the problems of narrow application range and few types of extraction heads, and achieve the effect of increasing adsorption capacity and expanding the selection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

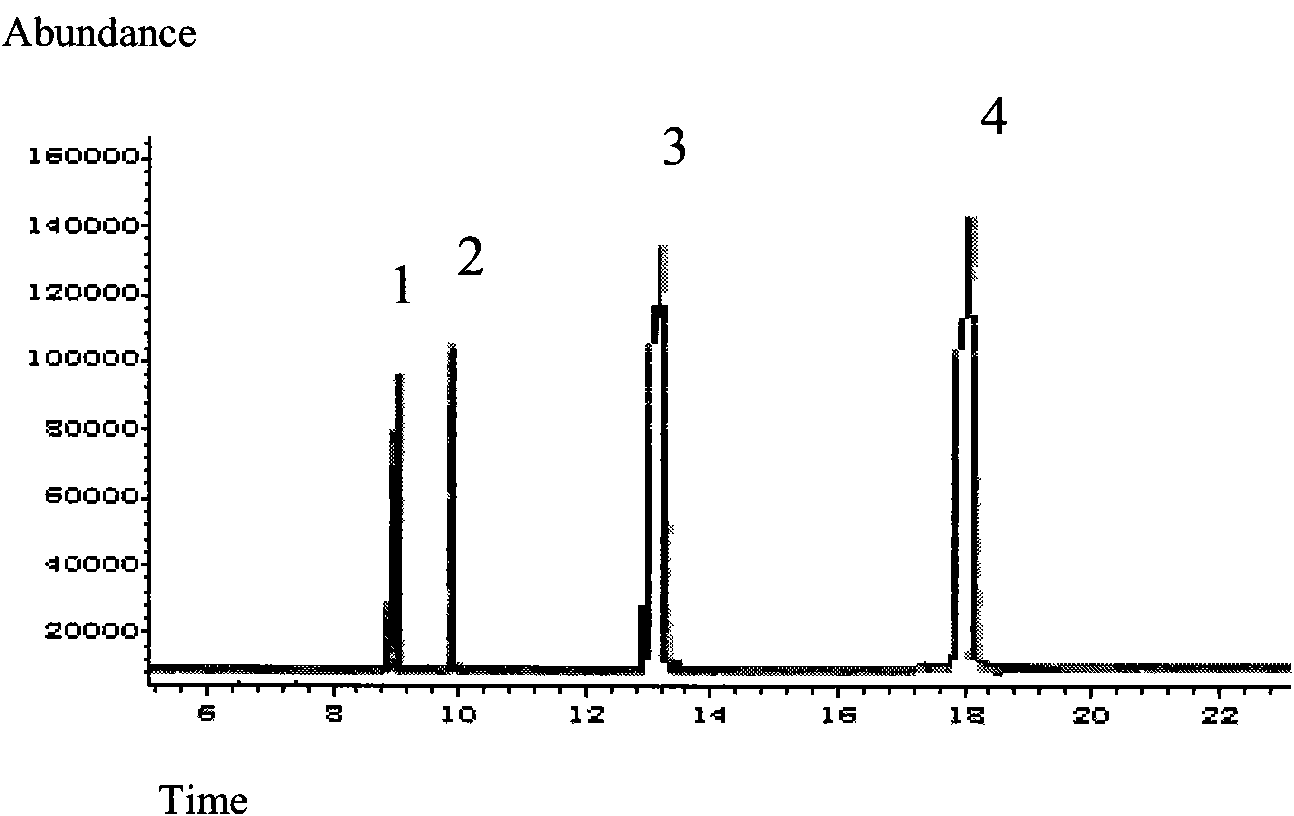

Embodiment 1

[0034] The preparation method of embodiment 1β-cyclodextrin matrix solid-phase microextraction extraction tip:

[0035] (1) Selection and pretreatment of quartz fibers:

[0036] Select a quartz fiber with a length of 20mm and a diameter of 0.1mm, soak it in dichloromethane solution to remove the polyamide protective layer, etch it with hydrogen fluoride for 10min, and finally wash it with deionized water until it is neutral. drying;

[0037] (2), production of solid-phase microextraction head:

[0038] Take 400 mg of hydroxyl-terminated polydimethylsiloxane, dilute it with 600 μl of dichloromethane, add 130 mg of β-cyclodextrin, 100 mg of hydrogen-containing silicone oil, 100 μl of methyltrimethoxysilane and 100 μl of trifluoroacetic acid, stir well, Prepare the sol, place the quartz fiber treated in step (1) in the sol for 30 minutes, take it out, form a gel at room temperature for 12 hours, and carry out temperature-programmed aging under the protection of nitrogen, keep a...

Embodiment 2

[0039] Example 2 The preparation method of β-cyclodextrin matrix solid-phase microextraction head:

[0040] (1) Selection and pretreatment of quartz fibers:

[0041] Select a quartz fiber with a length of 20mm and a diameter of 0.1mm, soak it in dichloromethane solution to remove the polyamide protective layer, then etch it with hydrogen fluoride for 10min, and finally rinse it with deionized water until it is neutral, and bake it under a nitrogen flow at 120°C Dry;

[0042] (2) Production of solid-phase microextraction head: Take 400 mg of hydroxyl-terminated polydimethylsiloxane, dilute it with 600 μl of dichloromethane, add 130 mg of β-cyclodextrin, 100 mg of hydrogen-containing silicone oil, and 50 μl of glycidyl oxide Propyltrimethylsilane, 50 μl of tetraethoxysilane and 100 μl of trifluoroacetic acid were fully stirred to obtain a sol, and the quartz fiber treated in step (1) was placed in the sol for 30 minutes, then taken out, and placed at room temperature The gel w...

Embodiment 3

[0043] Example 3 The preparation method of β-cyclodextrin matrix solid-phase microextraction head:

[0044](1) Selection and pretreatment of quartz fibers: select quartz fibers with a length of 20 mm and a diameter of 0.1 mm, soak them in dichloromethane solution to remove the polyamide protective layer, etch them with hydrogen fluoride for 10 minutes, and finally use deionized Rinse with water until neutral, and dry under nitrogen flow at 135°C;

[0045] (2) Production of solid-phase microextraction head: Take 400 mg of hydroxyl-terminated polydimethylsiloxane, dilute it with 600 μl of dichloromethane, add 170 mg of β-cyclodextrin, 120 mg of hydrogen-containing silicone oil, and 90 μl of methyltrimethoxy base silane and 110 μl trifluoroacetic acid, stir well to obtain a sol, place the quartz fiber treated in step (1) in the sol for 40 minutes, take it out, form a gel at room temperature for 12 hours, and carry out a temperature program under the protection of nitrogen Aging,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com