Process for extracting potassium chloride from native sylvite ore

A technology of potassium halite and potassium chloride, which is applied in the field of extracting industrial and agricultural potassium chloride products that meet national standards, can solve the problems of inconvenient use of primary particles, poor product quality, and high energy consumption for grinding, and achieve large Large-scale industrial production, low production cost, and the effect of coarse grinding particle size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

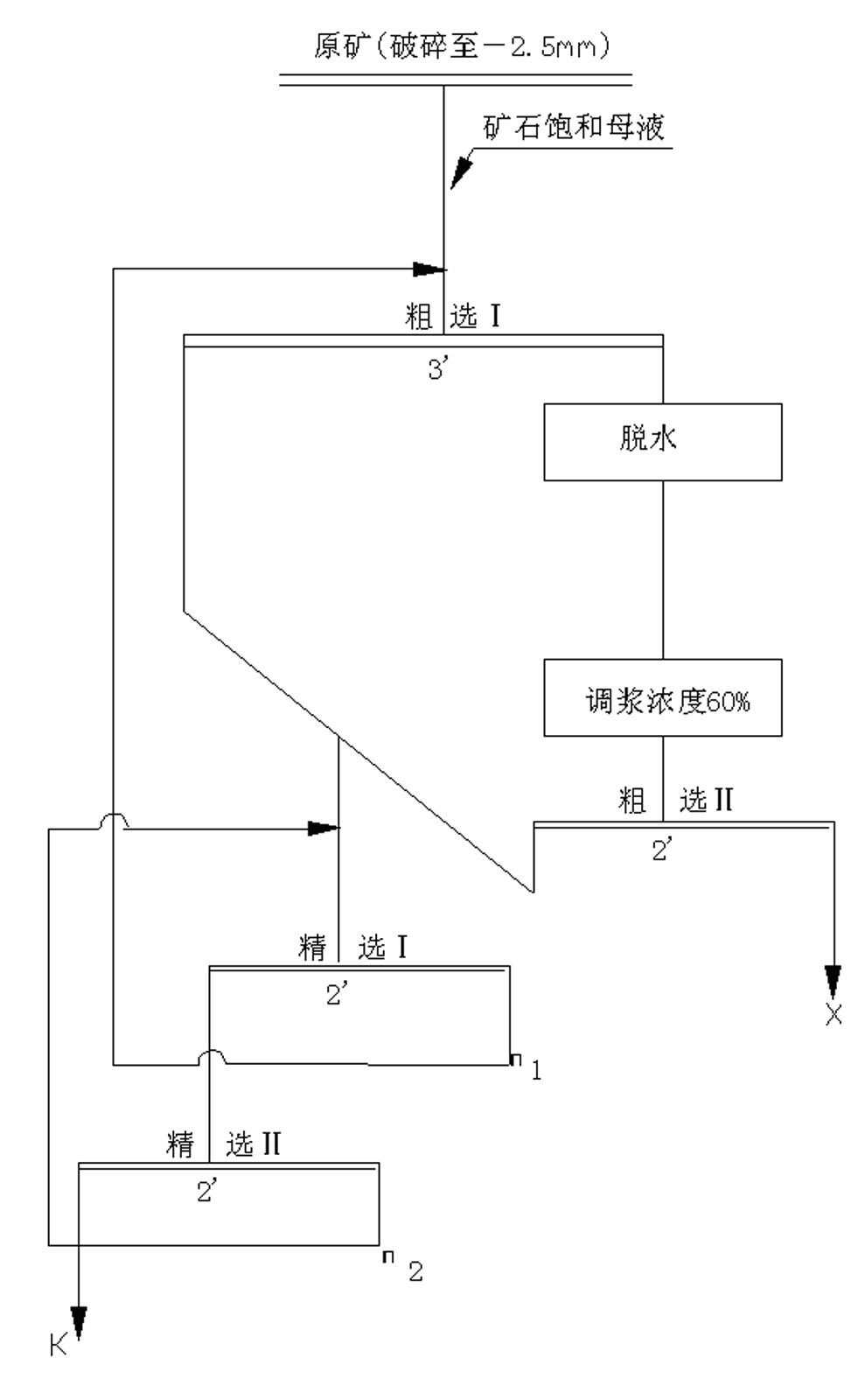

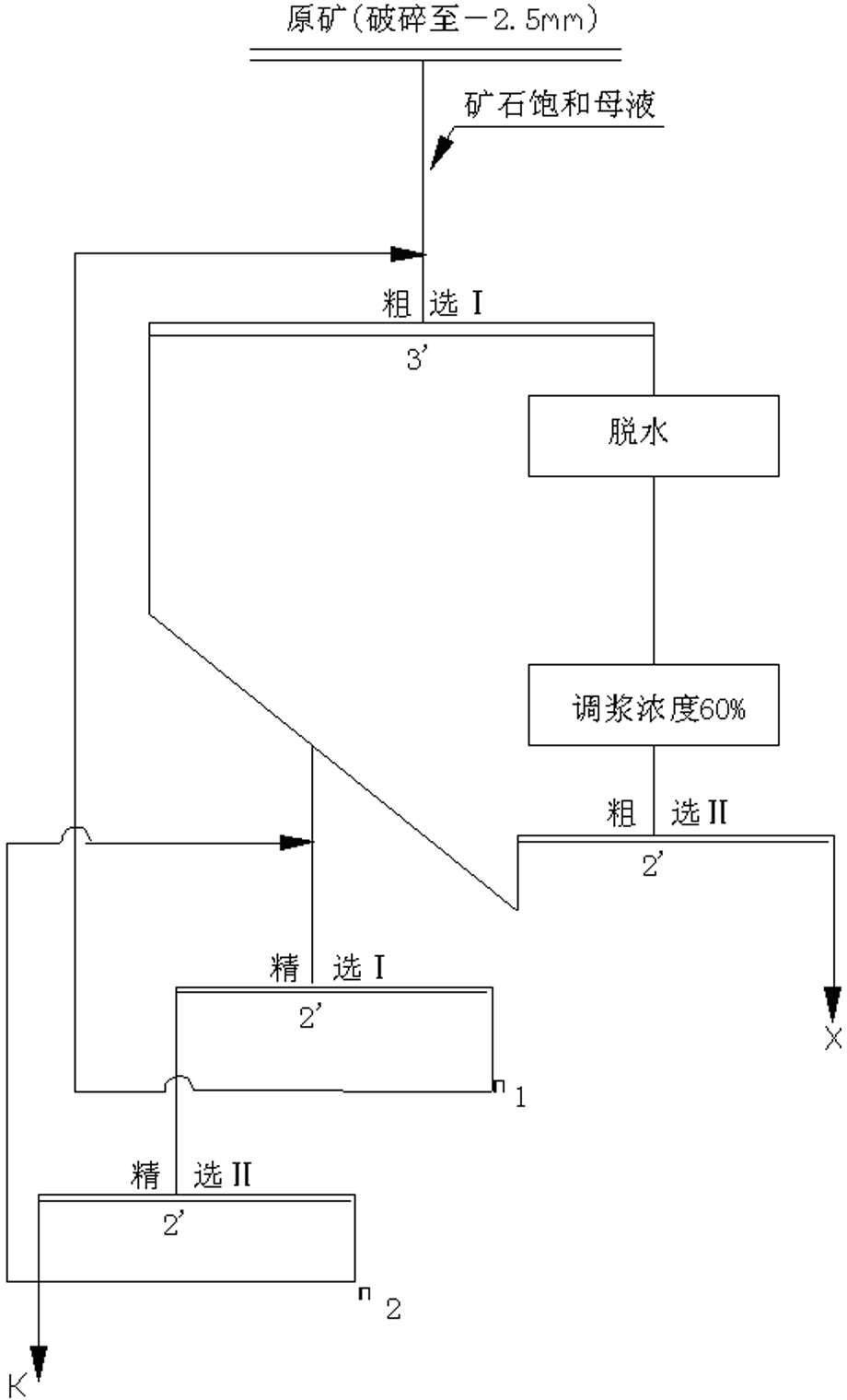

Image

Examples

Embodiment 1

[0018] (1) Grind potassium halite (containing 42.92% KCl) to below -8 mesh (-2.35mm); Add collector octadecyl fatty amine 150 g / ton, auxiliary collector unsaturated aliphatic hydrocarbon (C 16 ) 1000 g / ton, add inhibitor carboxymethyl cellulose 100 g / ton at the same time, flotation time 3 minutes; Octyl fatty amine 100 g / t, auxiliary collector unsaturated aliphatic hydrocarbon (C 16 ) 500 g / t for slurry flotation, the flotation time is 2 minutes; for the selection without adding chemicals, the flotation time for the two selections is 2 minutes, the KCl content of the flotation concentrate is 95.84%, and the recovery rate is 91.82%. (4) Concentrate washing, according to flotation concentrate: flotation mother liquor: water (mass ratio) is 8:10:1, add washing medium to wash and filter, test results: Potassium chloride concentrate can be obtained, KCl content 97.84 %,K + The recovery rate is 97.14%.

Embodiment 2

[0020] (1) Grind potash halite (containing 40.75% KCl) to below -8 mesh (-2.35mm); Add collector cetyl fatty amine 150 g / ton, auxiliary collector unsaturated aliphatic hydrocarbon (C 14 ) 900 g / ton, and add inhibitor carboxyethyl cellulose 100 g / ton at the same time, and the flotation time is 3 minutes; Hexaalkyl fatty amine 100 g / t, auxiliary collector unsaturated aliphatic hydrocarbon (C 14 ) at 400 g / t for slurry flotation, the flotation time is 2 minutes; for selection without adding chemicals, the two selection flotation times are both 2 minutes, the KCl content of the flotation concentrate is 95.24%, and the recovery rate is 91.28%. (4) Concentrate washing, according to flotation concentrate: flotation mother liquor: water (mass ratio) is 8:10:1, add washing medium to wash and filter, test results: Potassium chloride concentrate can be obtained, KCl content 97.45 %,K + The recovery rate is 97.40%.

Embodiment 3

[0022] (1) Grind potash rock salt ore (containing 38.85% KCl) to below -8 mesh (-2.35mm); Add collector tetradecyl fatty amine 250 g / ton, auxiliary collector unsaturated aliphatic hydrocarbon (C 10 ) 1100 g / ton, add inhibitor hydroxymethyl cellulose 100 g / ton at the same time, flotation time 3 minutes; Dialkyl aliphatic amine 250 g / t, auxiliary collector unsaturated aliphatic hydrocarbon (C 8 ) 600 g / t for pulping flotation, the flotation time is 2 minutes; the selection does not add chemicals, the two selection flotation times are 2 minutes, the KCl content of the flotation concentrate is 96.10%, and the recovery rate is 90.98%. (4) Concentrate washing, according to flotation concentrate: flotation mother liquor: water (mass ratio) is 8:10:1, add washing medium to wash and filter, test results: Potassium chloride concentrate can be obtained, KCl content 97.95 %,K + The recovery rate is 97.23%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com