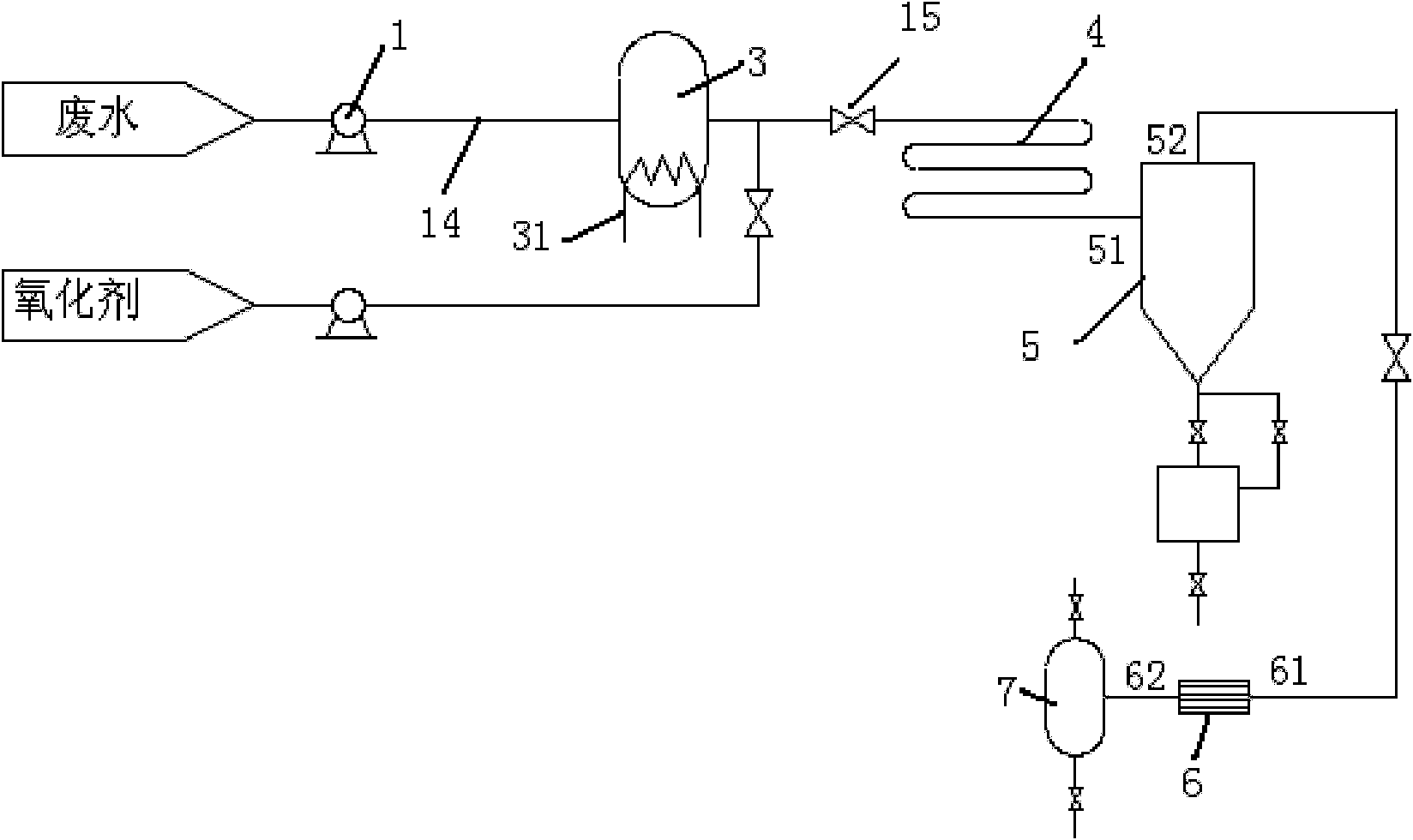

System and method for processing blue-green algae by using supercritical water oxidation (SCWO)

A supercritical water oxidation and supercritical technology, which is applied in the direction of oxidized water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of complex structure and high cost of wastewater treatment system, and achieve convenient treatment, fast response speed, and efficient treatment system and the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

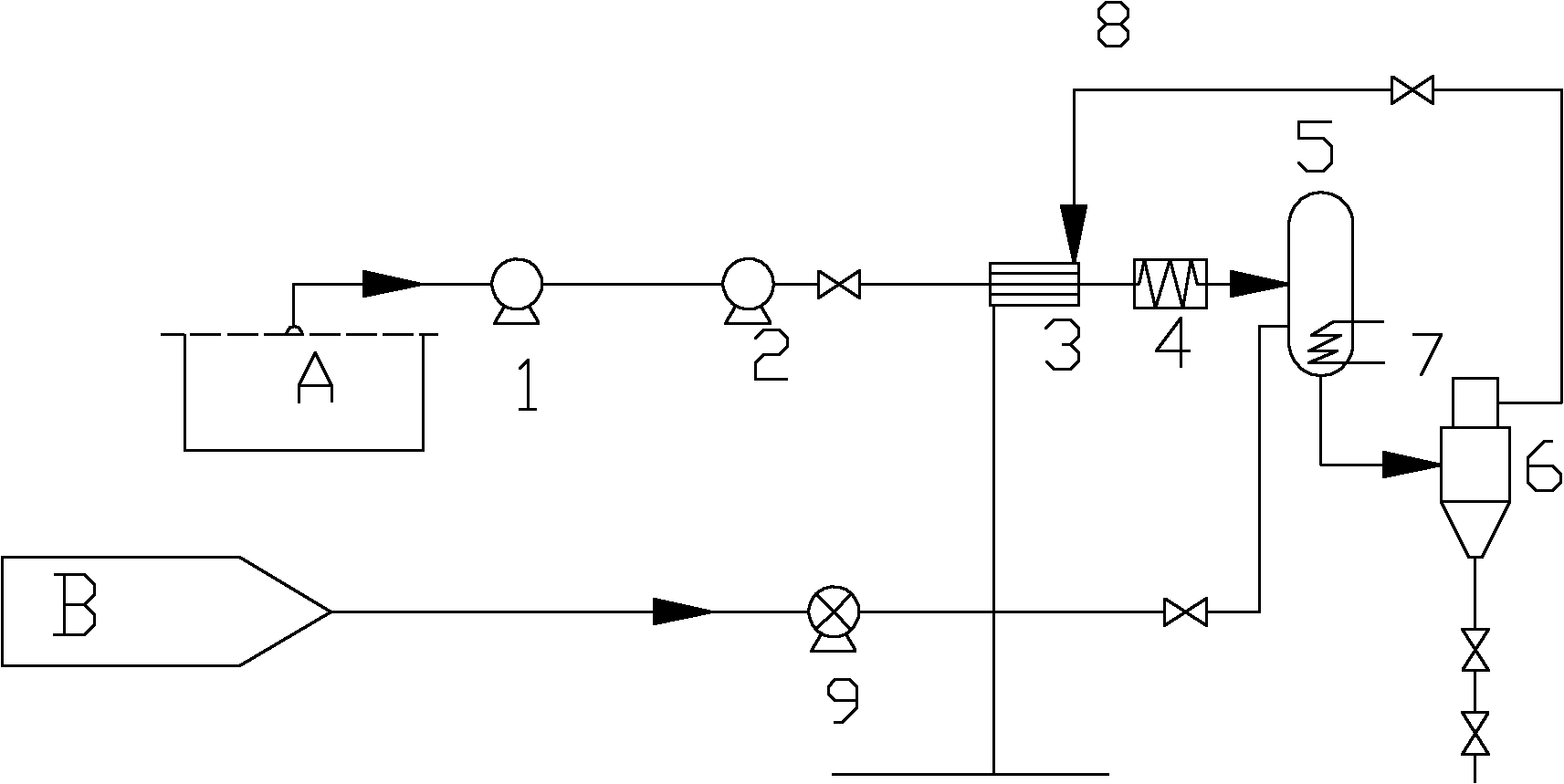

Embodiment 1

[0042] Such as figure 2 As shown, a system utilizing supercritical water oxidation method to treat cyanobacteria comprises a water pump 1, a high-pressure plunger pump 2, a heat exchanger 3, a preheater 4, a supercritical reactor 5 and a high-pressure hydrocyclone 6, each Parts are sequentially connected by delivery pipeline 8 . The supercritical reactor 5 is a pressure-resistant container with a heater 7 inside.

[0043] A heat exchanger 3 is also provided on the delivery pipeline between the high-pressure plunger pump 2 and the preheater 4 . The output port of the high-pressure plunger pump 2 is connected to the inlet of the heat exchanger 3, and the cyanobacteria-contaminated water output by the high-pressure plunger pump 2 is input into the heat exchanger 3 as a cold medium, and the cold medium after heat exchange is input into the preheater 4, and then Then enter the supercritical reactor 5; the outlet of the supercritical reactor 5 is connected to the inlet of the hig...

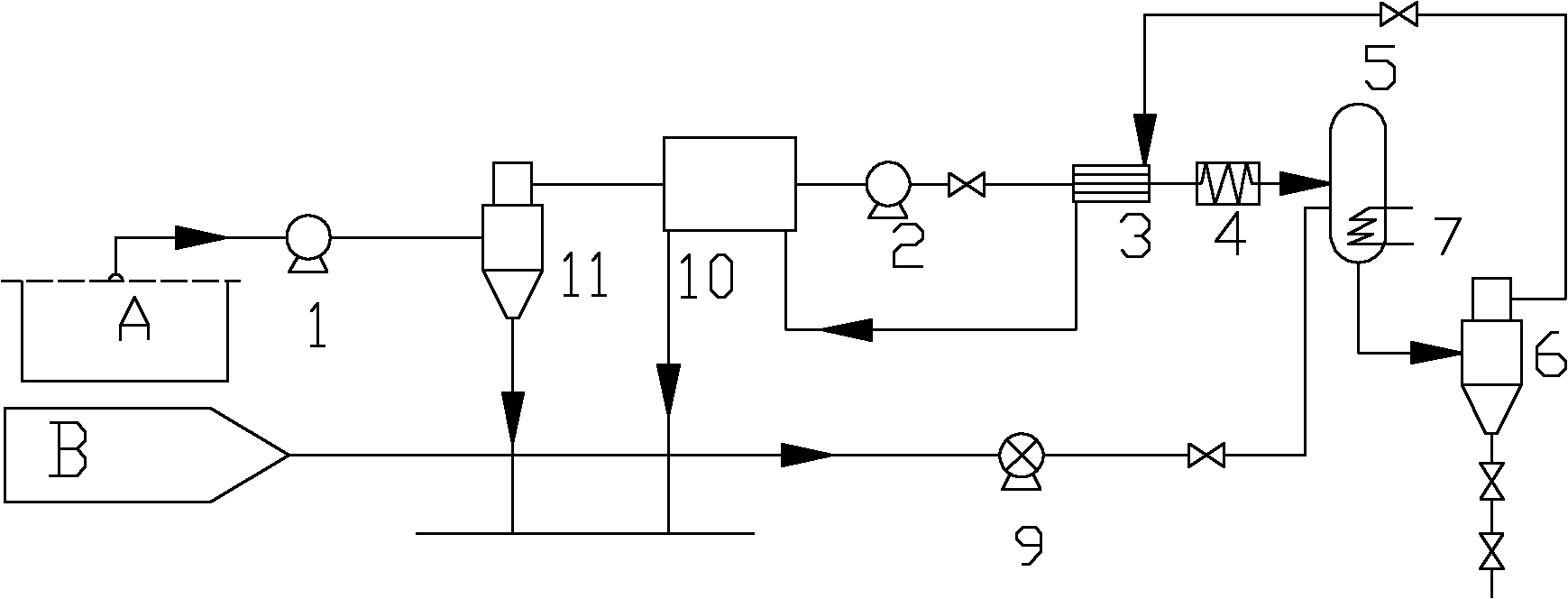

Embodiment 2

[0052] Such as image 3 As shown, this example is basically the same as Example 1, except that a filter 12 is provided between the water pump 1 and the high-pressure plunger pump 2 . A low-pressure hydrocyclone 11 and an evaporator 10 are arranged between the water pump 1 and the high-pressure plunger pump 2, and the non-decomposed cyanobacteria-contaminated water to be treated extracted by the water pump 1 is separated from a part of the water by the low-pressure hydrocyclone 2, passed through After the evaporator 10 further removes water, the COD concentration of the cyanobacteria polluted water to be treated is increased. Moreover, the speed of the hydrocyclone 2 can also be controlled, so that the delivery speed of the cyanobacteria-contaminated water to be treated can be adjusted as required.

[0053] A method utilizing supercritical water oxidation to process cyanobacteria, comprising the following steps:

[0054] (1) After the cyanobacteria-contaminated water to be tr...

Embodiment 3

[0062] Such as Figure 4 As shown, this example is basically the same as Example 1, except that a filter 12 is provided between the water pump 1 and the high-pressure plunger pump 2 . The undecomposed cyanobacteria-contaminated water to be treated pumped out by the water pump 1 is dehydrated through the filter 12, thereby increasing the concentration of total organic carbon in the cyanobacteria-contaminated water to be treated.

[0063] A method for processing cyanobacteria by supercritical water oxidation, comprising the following steps:

[0064] (1) After the cyanobacteria-contaminated water to be treated is pumped out from the lake with the water pump 1, the water is removed by the filter 12, pressurized by the high-pressure plunger pump 2, preheated by the heat exchanger 3 and the preheater 4, and enters supercritical Reactor 5;

[0065] (2) After filling part of the cyanobacteria-contaminated water to be treated in the supercritical reactor 5, close the outlet valve of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com