MBR wastewater treating system with double circular grooves

A wastewater treatment system and ring ditch technology, applied in the field of wastewater treatment, can solve the problems of denitrification, turbidity of effluent, poor phosphorus removal effect, etc., and achieve the effects of improving oxygen utilization, improving nitrogen removal efficiency, and reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

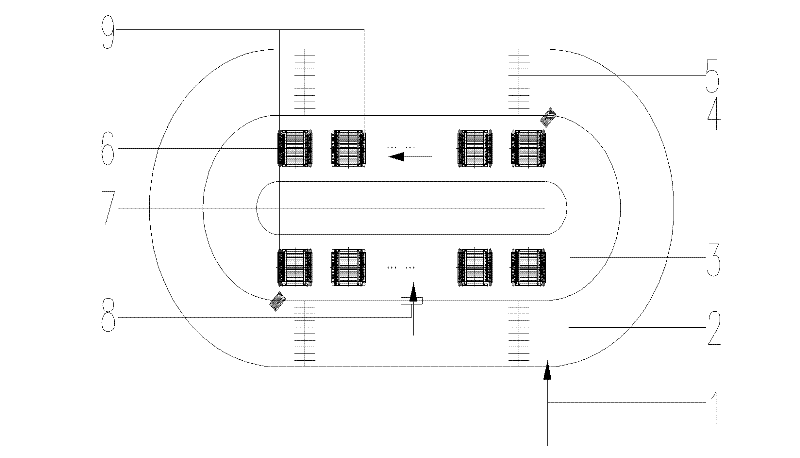

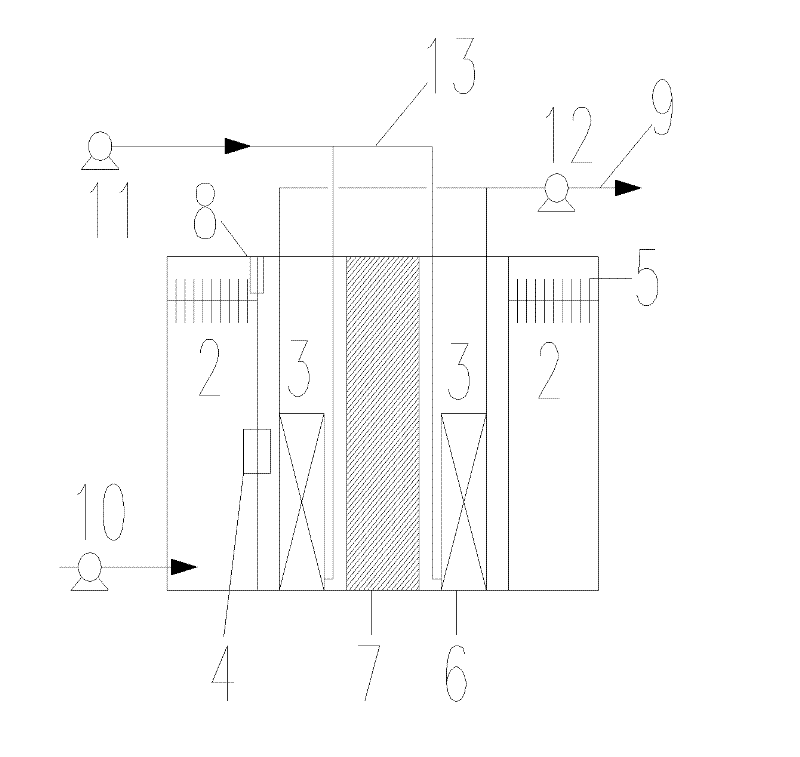

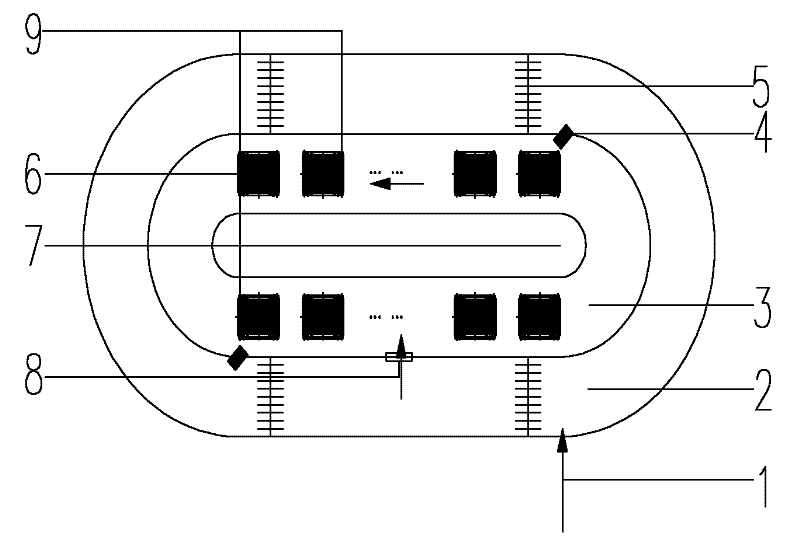

[0026] A set of Shuanghuangou MBR wastewater treatment system, such as figure 1 , 2 Shown, comprise water inlet pipe 1 (inlet water pump 10 is housed on pipeline), water outlet pipe 9 and the water treatment area that is provided with MBR membrane bioreactor 6, described water treatment area includes the external communication channel that is separated by pool wall 2 and the internal communication channel 3, the water inlet pipe 1 communicates with the external communication channel 2, and the outlet pipe 1 communicates with the internal communication channel 3; the MBR membrane bioreactor 6 is arranged in the internal communication channel 3, and the MBR membrane The bioreactor 6 is equipped with an aeration device. An overflow weir 8 is provided on the upper part of the pool wall between the external communication channel 2 and the internal communication channel 3, and four groups of pushers 4 and return ports are arranged symmetrically; There are 4 groups of aeration rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com