Thick mash alcohol fermentation process for mixing tapioca by using molasses hydrolyzate

A technology for alcohol fermentation and tapioca flour is applied in the field of concentrated mash alcohol fermentation technology, and achieves the effects of reduced energy consumption for distillation, reduced production cost and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0017] Embodiment: (the total sugar content of molasses hydrolyzate accounts for 20% of the total sugar of powder slurry)

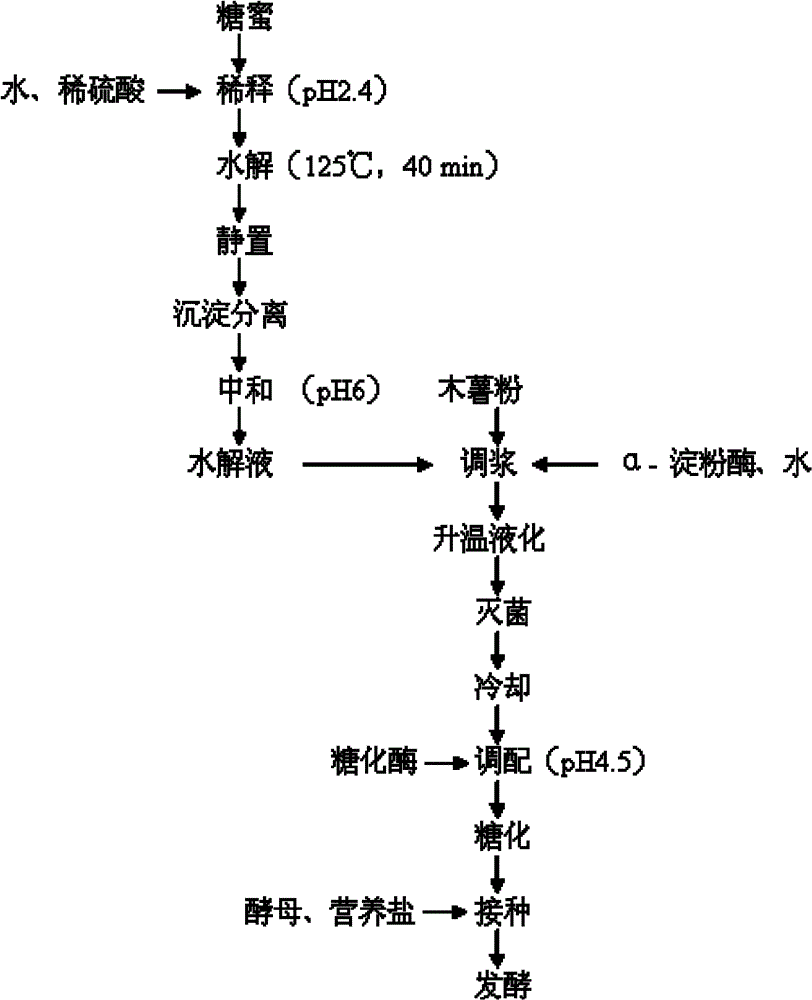

[0018] A kind of thick mash alcoholic fermentation process that utilizes molasses hydrolyzate to carry out cassava flour slurry adjustment, comprises the following steps:

[0019] (1) Hydrolysis of molasses: put molasses in a 1000mL beaker, add water to dilute until the Brix is 30°Bx, then adjust the pH to 2.4 with 20% sulfuric acid solution, keep it in a sterilizer at 125°C for 40min, take it out and let it stand for 1h. The precipitate was separated, and the separated supernatant was neutralized to pH 6.0 with 6 mol / L sodium hydroxide solution to obtain a molasses hydrolyzate with a sugar content of 19.2 g / 100 g.

[0020] (2) Using molasses hydrolyzate for cassava flour mixing: Weigh 18.38kg of absolute-dried cassava flour with a starch content of 70% and 18.59kg of molasses hydrolyzate prepared in step (1), and add 20 kg of water to mix. Put it in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com