Method for manufacturing lattice graded buffer layer

A technology of graded buffer layer and graded layer, applied in the field of semiconductor, can solve the problems such as the inability to eliminate mismatch, the high density of threading dislocations on the surface of the structure and the device, the influence of the interface material of the heterojunction material and the performance of the device, etc. Achieve the effect of reducing dependence, overcoming performance degradation, and controlling defect density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

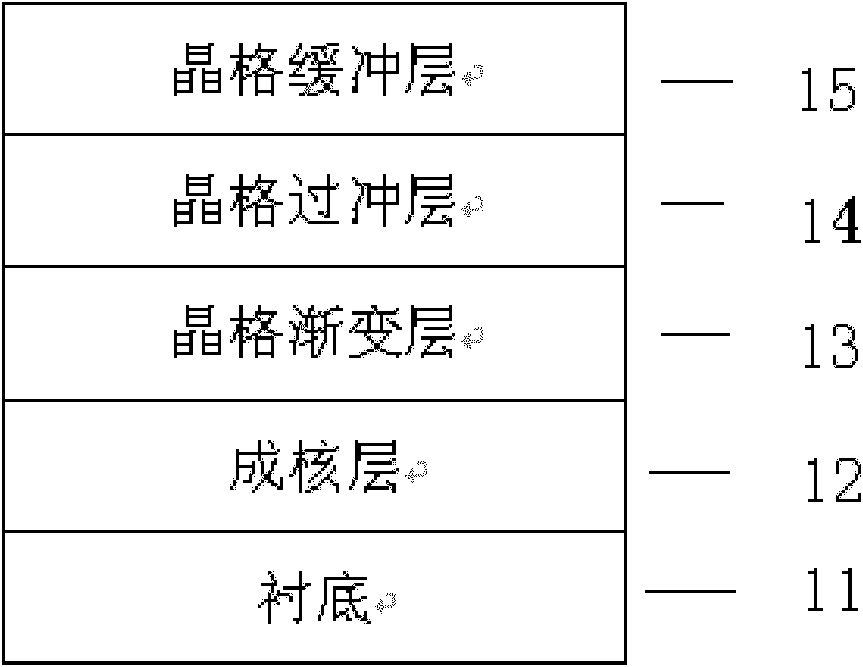

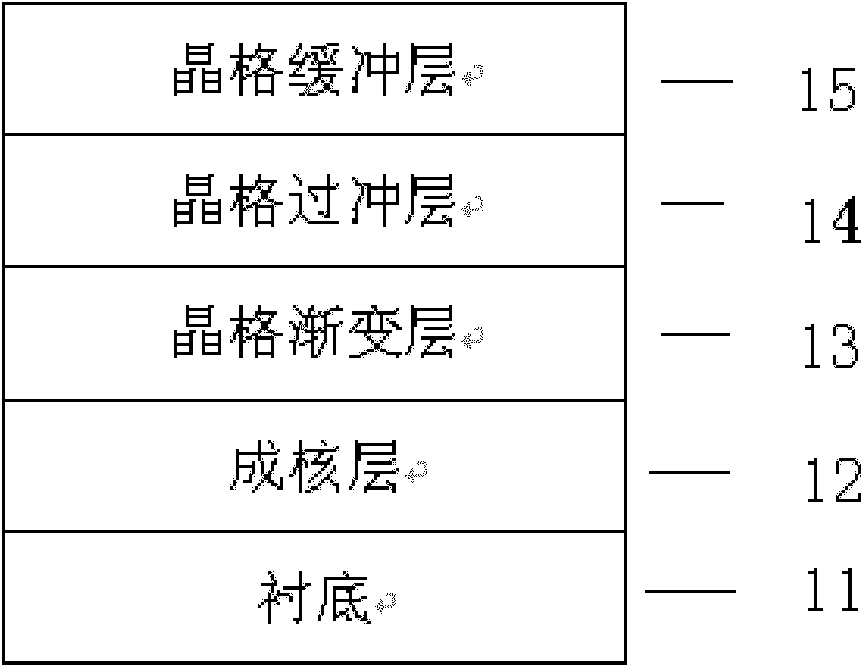

[0025] A preparation method of a lattice gradient buffer layer, the steps are:

[0026] Step (1): use germanium (Ge) single crystal as the substrate 11; the substrate material can be germanium, silicon, and III-V and II-VI group materials or their combination, including gallium arsenide, indium phosphide , gallium phosphide, gallium nitride, gallium antimonide, etc.; the substrate surface may have (100), (110) or (111) crystallographic directions, or other index plane directions, as well as directions in other directions including the above directions 0-15 degree deflection angle.

[0027] Step (2): Utilize existing epitaxy techniques such as metal organic chemical vapor deposition (MOCVD), molecular beam epitaxy (MBE) and liquid phase epitaxy (LPE), carry out the epitaxial growth of material; In order to make the core functional layer of the present invention application— —The structure of the lattice gradient buffer layer is not affected by the defects of the substrate. Fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com