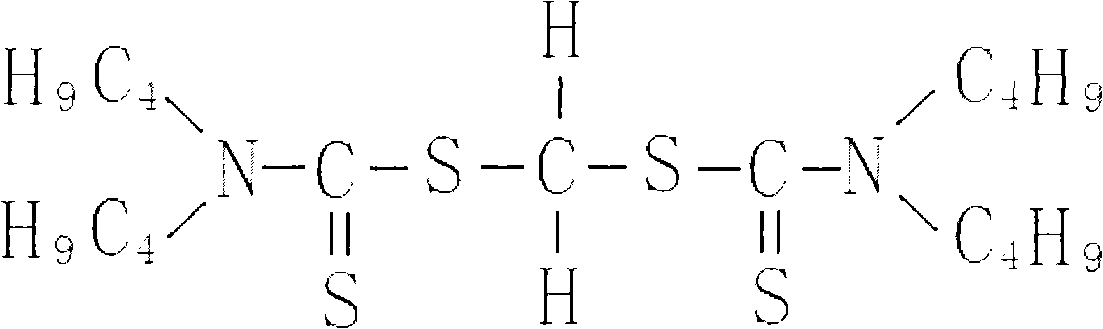

Application of methylne bis (bitutyl dithio carbamate)

A technology of dibutyldithiocarbamate and methylenebis is applied in the field of methylenebis as a flotation selective collector for copper-molybdenum ore, which can solve the influence of flotation index, influence on application and production The problem of high cost, to achieve the effect of low production cost, convenient operation and improved metal recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

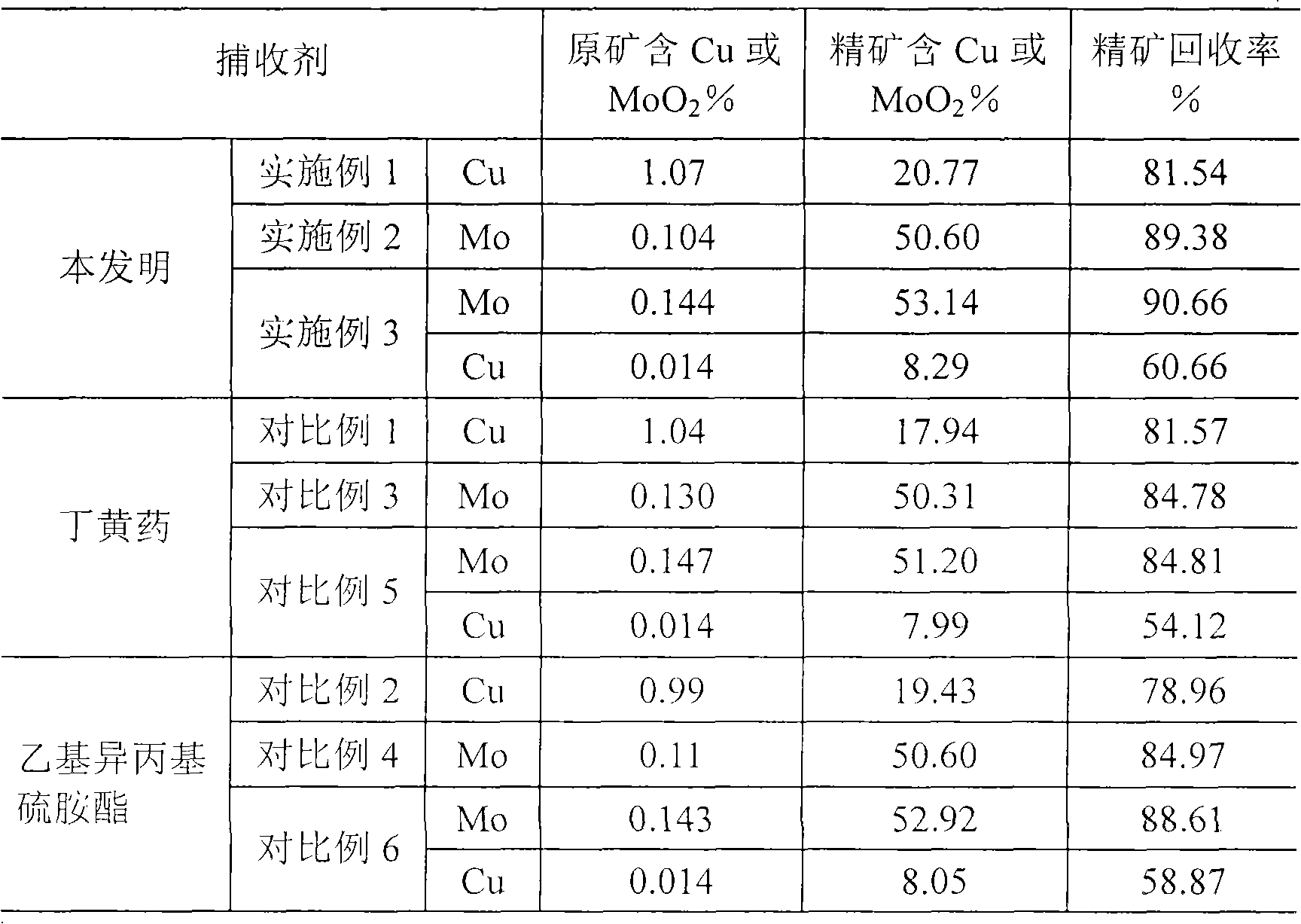

Embodiment 1

[0014] Crushing and grinding the sulfide ore containing 1.07% copper and 15.89% copper oxidation rate, adding water until the pulp contains 30% solid weight, adding 300 g / ton of activator sodium sulfide, 1000 g / ton of raw ore inhibitor, water glass, and adding sub Methyl bis (dibutyl dithiocarbamate) 10 grams per ton of raw ore, after one roughing, three times of sweeping and three times of beneficiation, the obtained copper concentrate contains 20.77% of Cu, and the recovery rate of Cu is 81.54%.

Embodiment 2

[0016] Crushing and grinding the sulfide ore containing 0.104% molybdenum, adding water until the slurry contains 33% solid weight, adding activator sodium sulfide 400 g / ton raw ore inhibitor water glass 1100 g / ton raw ore, and adding methylene bis(dibutyl Based on dithiocarbamate) 15 grams per ton of raw ore, after one roughing, three times of sweeping and three times of beneficiation, the molybdenum concentrate contains 50.60% molybdenum, and the recovery rate is 89.38%.

Embodiment 3

[0018] Crushing and grinding the molybdenum-copper sulfide ore containing 0.144% molybdenum and 0.014% copper, adding water until the pulp contains 35% solid weight, adding 500 grams / ton of activator sodium sulfide, 1800 grams / ton of water glass as an inhibitor, and Add 20 g / ton of methylene bis(dibutyldithiocarbamate) ore, and after one roughing, three times of sweeping and three times of beneficiation, the molybdenum concentrate contains 53.14% molybdenum, and the recovery rate is 90.66%. The copper mine contains 8.29% copper, and the copper recovery rate is 60.66%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com