Hollow carbon sphere and preparation method thereof

A technology of hollow spheres and cross-linked polystyrene, which is applied in the field of preparation of carbon hollow spheres, can solve the problems of complex process, poor control of product structure and morphology, and difficulty in industrial production, and achieve simple preparation process and easy industrial production Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

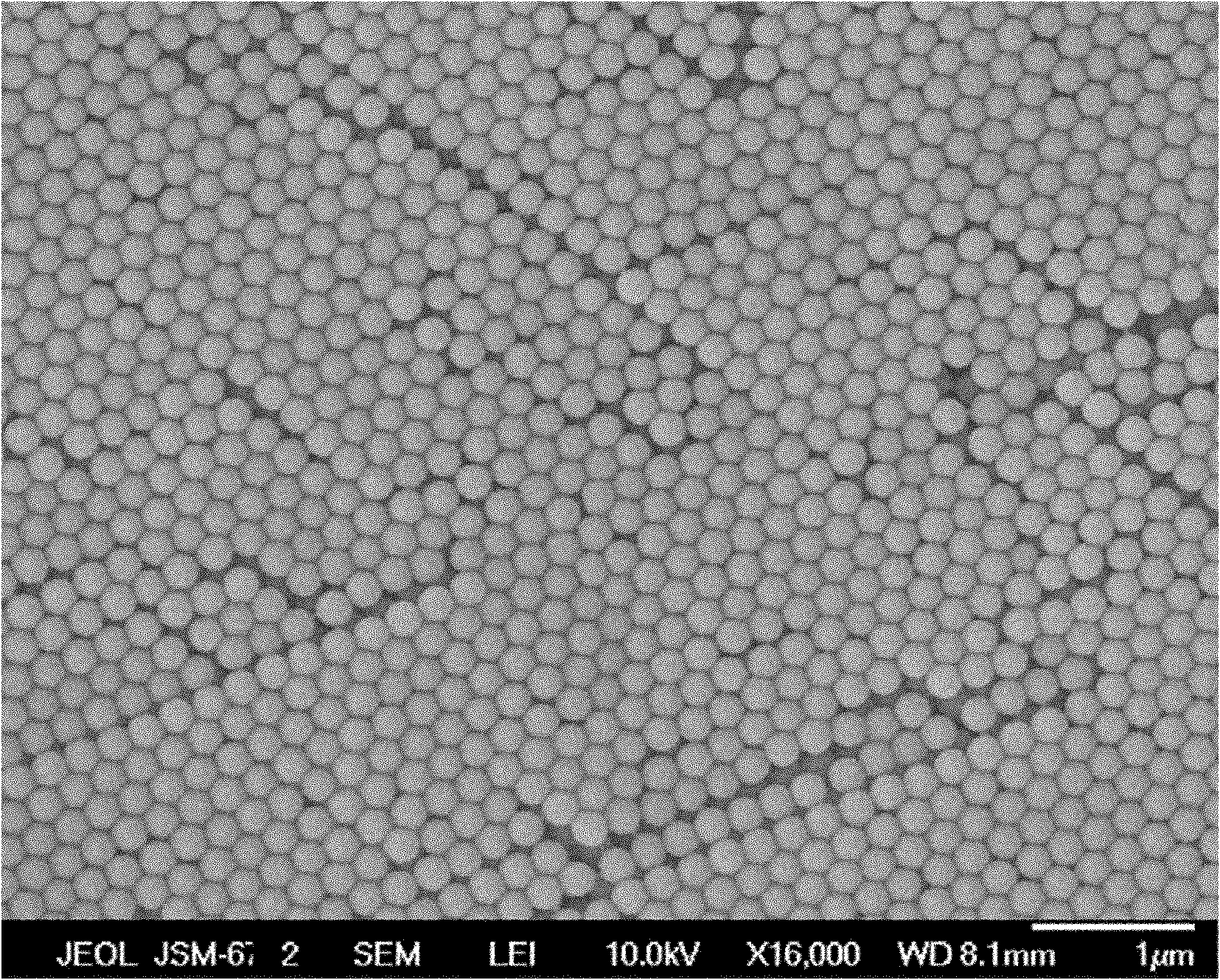

[0030] Embodiment 1, the preparation of carbon hollow sphere

[0031] (1) Preparation of cross-linked polystyrene spheres

[0032] 6g of polyvinylpyrrolidone (Mw=400,000g / mol) and 1.5g of 2,2'-azo[2-(2-imidazolin-2-yl)propane]dihydrochloride were dissolved in 250mL at 25°C. Add dropwise the mixture of 50g styrene and divinylbenzene monomer in deionized water (the mass percent composition of divinylbenzene in this mixture is 30%; In this system, 2,2'-azo[2-(2- Imidazolin-2-yl) propane] dihydrochloride, polyvinylpyrrolidone and the molar concentration of the mixture of styrene and divinylbenzene monomers are 22.12mmol / L, 0.048mmol / L and 1730mmol / L), the whole The dropwise addition process needs to be carried out under continuous stirring (stirring rate: 800r / min), then keep the stirring rate constant and raise the temperature to 80°C for 24 hours. After the reaction is completed, return to room temperature and centrifuge (centrifugal speed: min) washed 5 times with water to ob...

Embodiment 2

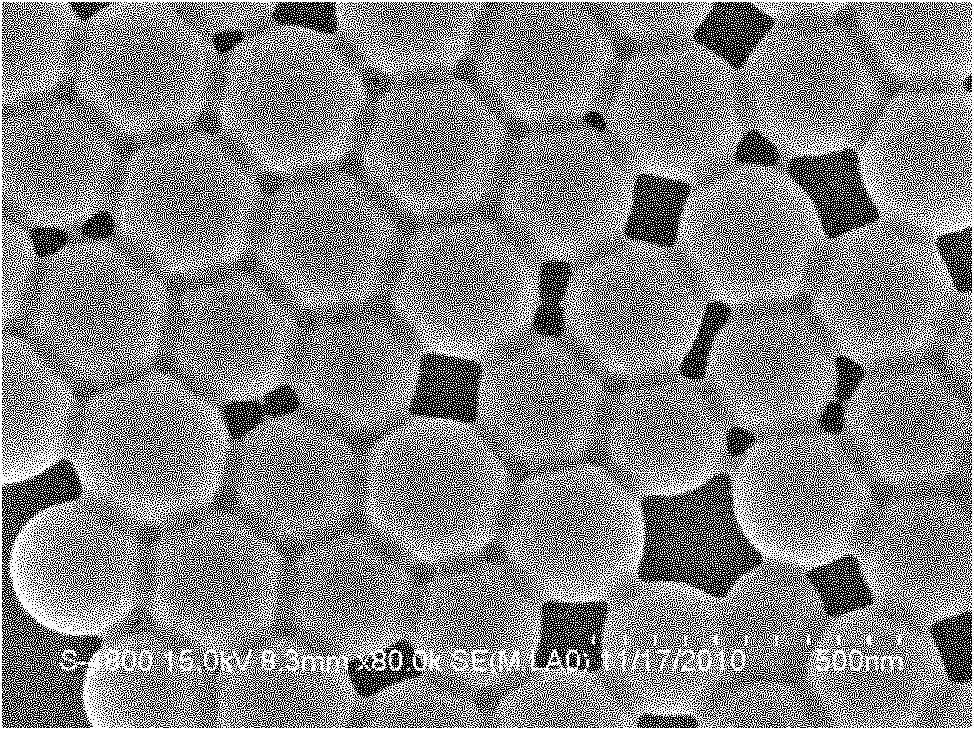

[0037] Embodiment 2, the preparation of carbon hollow sphere

[0038] (1) Preparation of cross-linked polystyrene spheres

[0039]Dissolve 2g of polyvinylpyrrolidone (Mw=500,000g / mol) and 350mg of 2,2'-azo[2-(2-imidazolin-2-yl)propane]dihydrochloride in 250mL at 25°C Add dropwise the mixture of 12.5g styrene and divinylbenzene monomer in water (the mass percent composition of divinylbenzene in this mixture is 50%; In this system, 2,2'-azo[2-(2- Imidazolin-2-yl) propane] dihydrochloride, polyvinylpyrrolidone and the molar concentration of the mixture of styrene and divinylbenzene monomers are 5.16mmol / L, 0.016mmol / L and 432mmol / L), the whole The dropwise addition process needs to be carried out under continuous stirring (stirring rate: 800r / min), then keep the stirring rate constant and raise the temperature to 65°C for 32 hours. After the reaction, return to room temperature and centrifuge (centrifugal speed: 10000r / min min) and washed 5 times with water to obtain 12 g of cr...

Embodiment 3

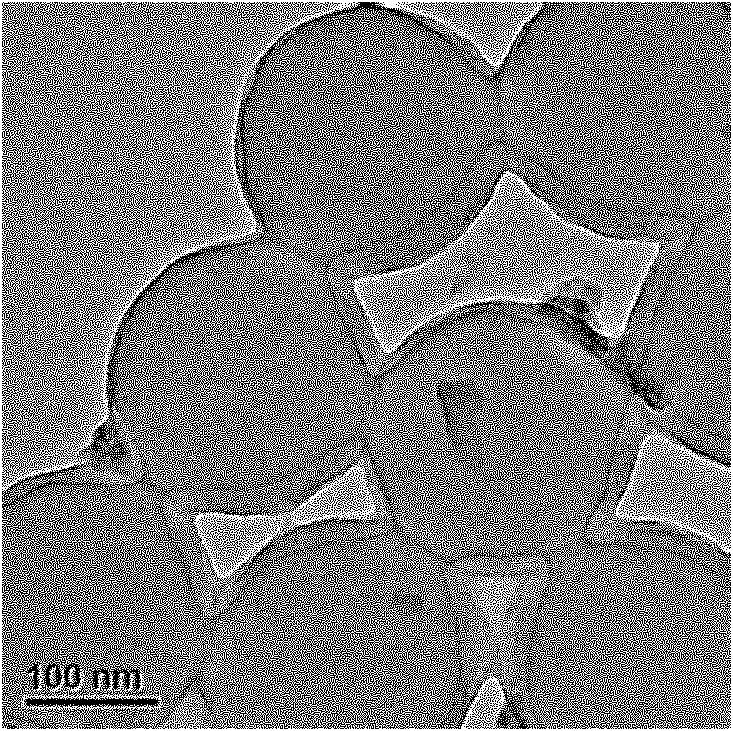

[0048] Embodiment 3, the preparation of carbon hollow sphere

[0049] (1) Preparation of cross-linked polystyrene spheres

[0050] Dissolve 6g of polyvinylpyrrolidone (Mw=600,000g / mol) and 3g of 2,2'-azo[2-(2-imidazolin-2-yl)propane]dihydrochloride in 250mL at 25°C Add dropwise the mixture of 80g styrene and divinylbenzene monomer in water (the mass percent composition of divinylbenzene in this mixture is 80%; In this system, 2,2'-azo[2-(2-imidazole The molar concentration of the mixture of phen-2-yl) propane] dihydrochloride, polyvinylpyrrolidone and styrene and divinylbenzene monomer is 44.24mmol / L, 0.04mmol / L and 1560mmol / L), the whole drop The addition process needs to be carried out under continuous stirring (stirring rate: 800r / min), then keep the stirring rate constant and raise the temperature to 80°C for 48 hours, then return to room temperature and centrifuge (centrifugal speed: 10000r / min) ) washed 5 times with water to obtain 75 g of cross-linked polystyrene ball...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Total pore volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com