Multistage continuous photocatalysis water purification reactor and water treatment method thereof

A photocatalyst and reactor technology, applied in the field of environmental purification, can solve the problems of photocatalyst shedding and loss, photocatalyst complexity, and failure to reach a practical scale.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

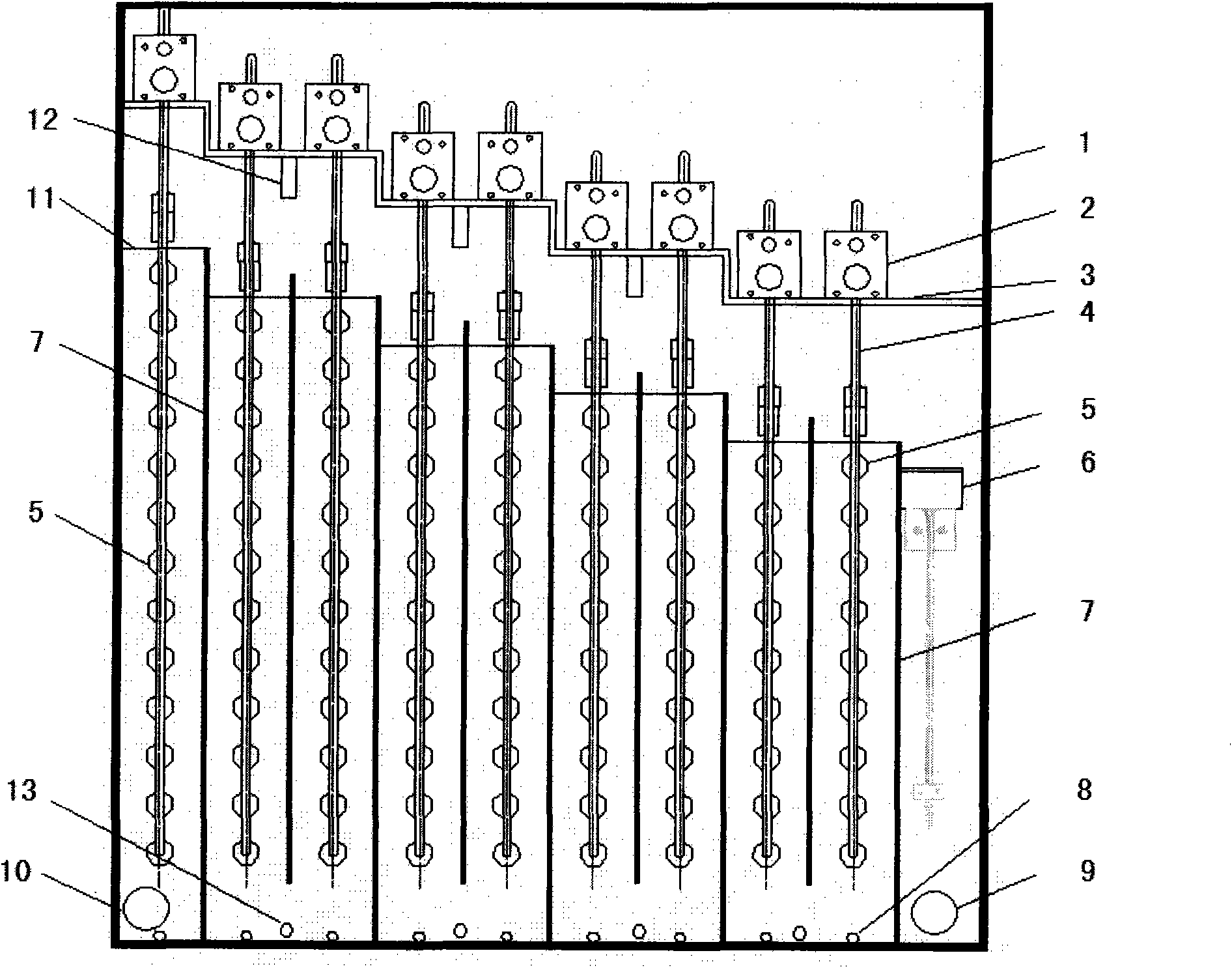

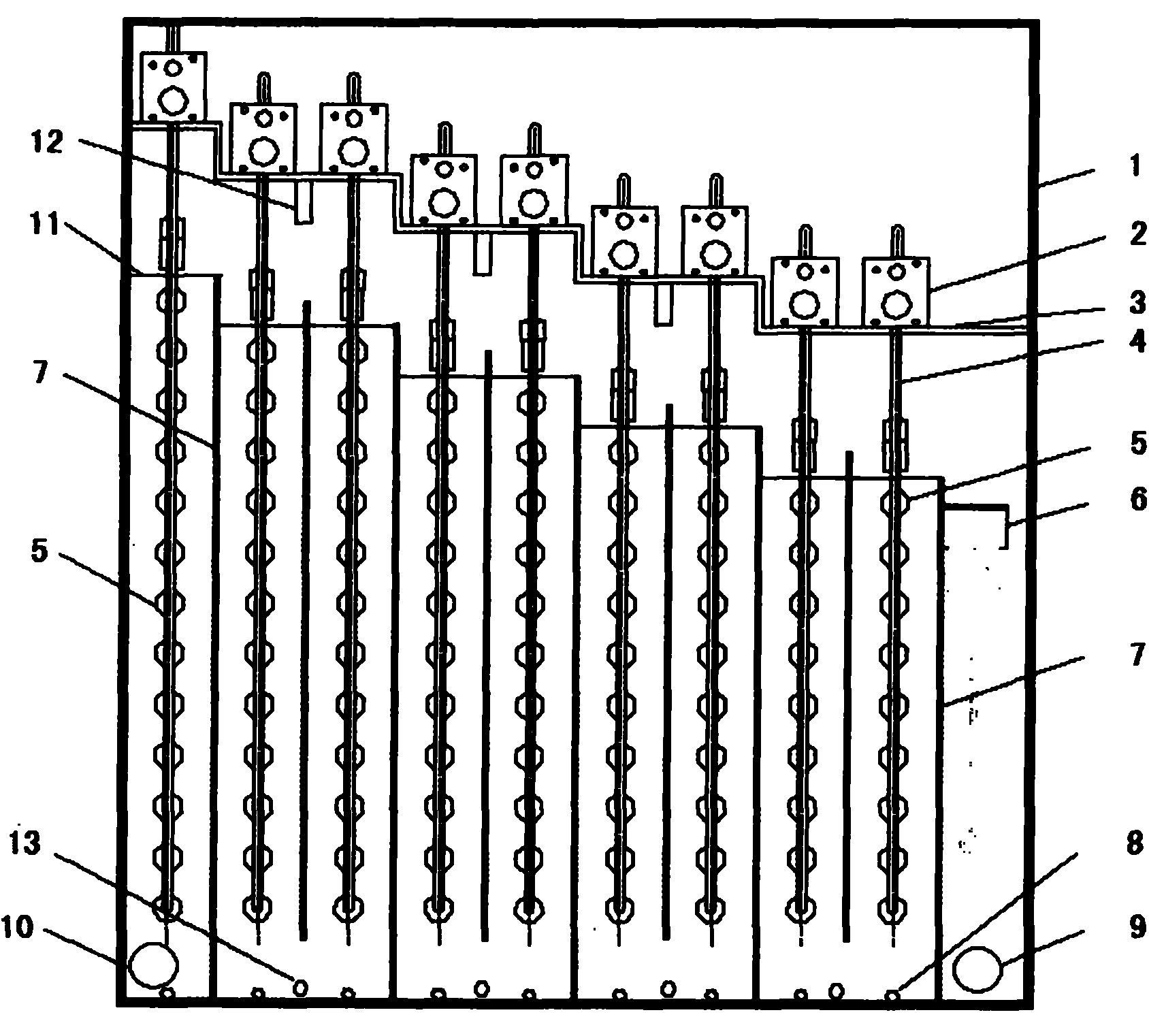

[0035] See figure 1 , the multi-stage continuous photocatalytic water purification reactor mainly includes three parts: contact pool, light source module, and switch control system;

[0036] Nine detachable partitions 7 made of polytetrafluoroethylene are fixedly installed in the nine slots of the inner pool wall of a rectangular contact pool made of stainless steel. The thickness of the detachable partition is Both are 3 cm, and the distance between the two adjacent detachable partitions 7 is 10 cm, and is defined as a single-stage processing system, with a total of 8-stage processing systems; the first detachable The space between the partition plate 7 and the pool wall of the contact pool is defined as the primary treatment system, and the space between the last removable partition plate 7 and the pool wall of the contact pool is defined as the final treatment system. system.

[0037] A water inlet 10 is provided at the bottom of the contact tank in the first-level treatm...

Embodiment 2

[0044] The basic structure of the multi-stage continuous photocatalytic water purification reactor is as in Example 1, which mainly includes three parts: the contact pool, the light source module, and the switch control system; only:

[0045] In the 5 draw-in slots of the inner pool wall of the contact pool, 5 detachable partitions 7 made of plexiglass are fixedly installed respectively. The thickness of the detachable partitions is 1 cm, and the adjacent two The distance between the removable partitions 7 is 28 centimeters, and is defined as a single-stage treatment system, a total of 4 treatment systems; the first piece of the removable partition 7 and the pool wall of the contact pool The space between them is defined as the primary treatment system, and the space between the last removable partition 7 and the pool wall of the contact pool is defined as the final treatment system.

[0046] The horizontal height of the 5 detachable partitions 7 that have been installed is th...

Embodiment 3

[0050] The basic structure of the multi-stage continuous photocatalytic water purification reactor is as in Example 1, which mainly includes three parts: the contact pool, the light source module, and the switch control system; only:

[0051] In the 8 slots of the inner pool wall of the contact pool, 8 removable partitions 7 made of stainless steel are fixedly installed respectively. The thickness of the removable partitions is 0.5 cm, and the adjacent two The distance between the detachable partitions 7 is 15 centimeters, and is defined as a single-stage treatment system, a total of 7 treatment systems; the first piece of detachable partitions 7 and the pool wall of the contact pool The space between them is defined as the primary treatment system, and the space between the last removable partition 7 and the pool wall of the contact pool is defined as the final treatment system.

[0052] The horizontal height of the installed detachable partition is that the level of the two ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com