Biodegradable aliphatic polyester / aromatic polyester multi-block copolymer and preparation method and application thereof

A multi-block copolymer and aliphatic polyester technology, which is applied in the field of biodegradable aliphatic polyester/aromatic polyester multi-block copolymer and its preparation and application, can solve the problem of limited impact strength improvement, fat Problems such as limited impact strength of family polyester

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

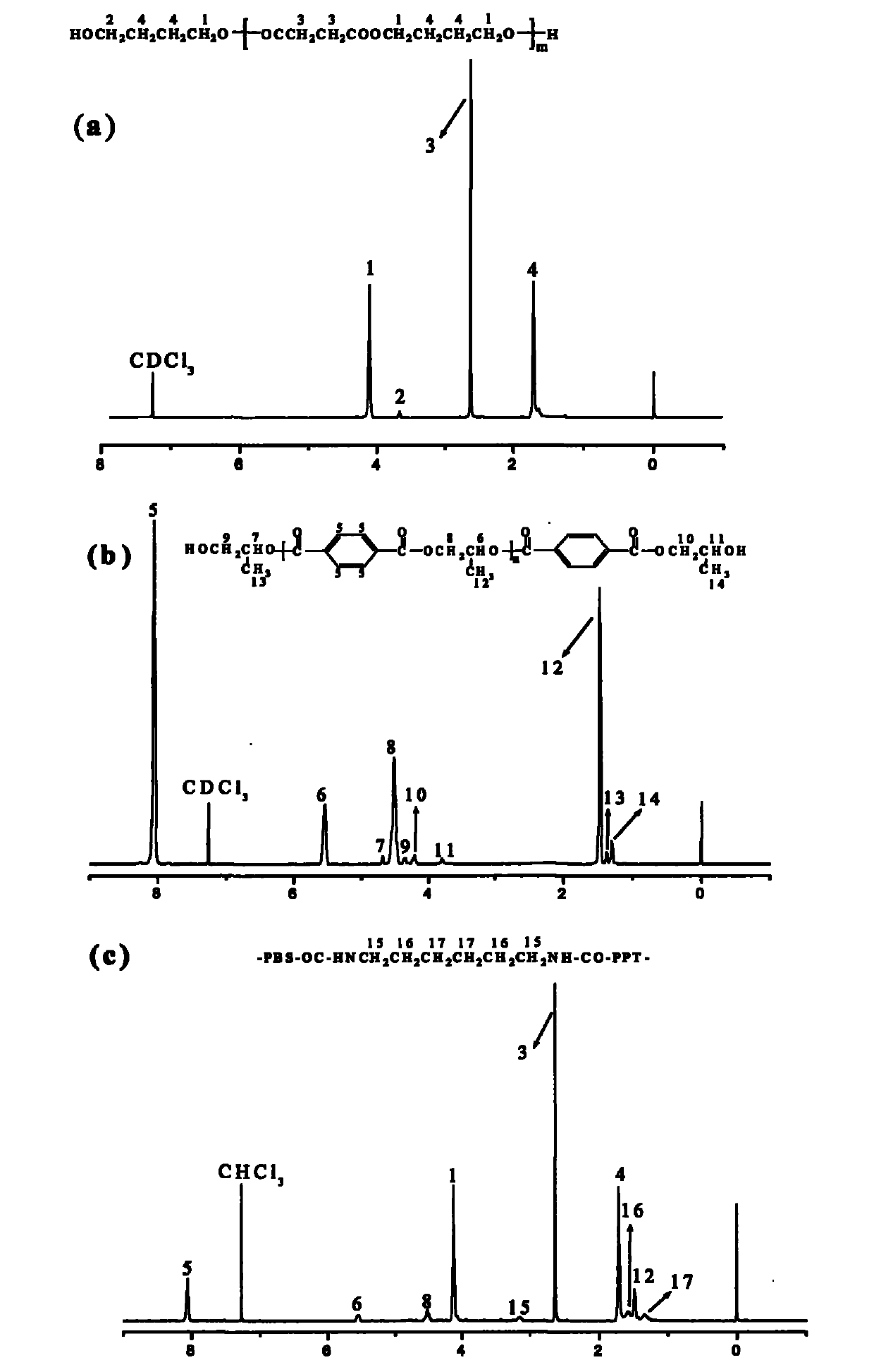

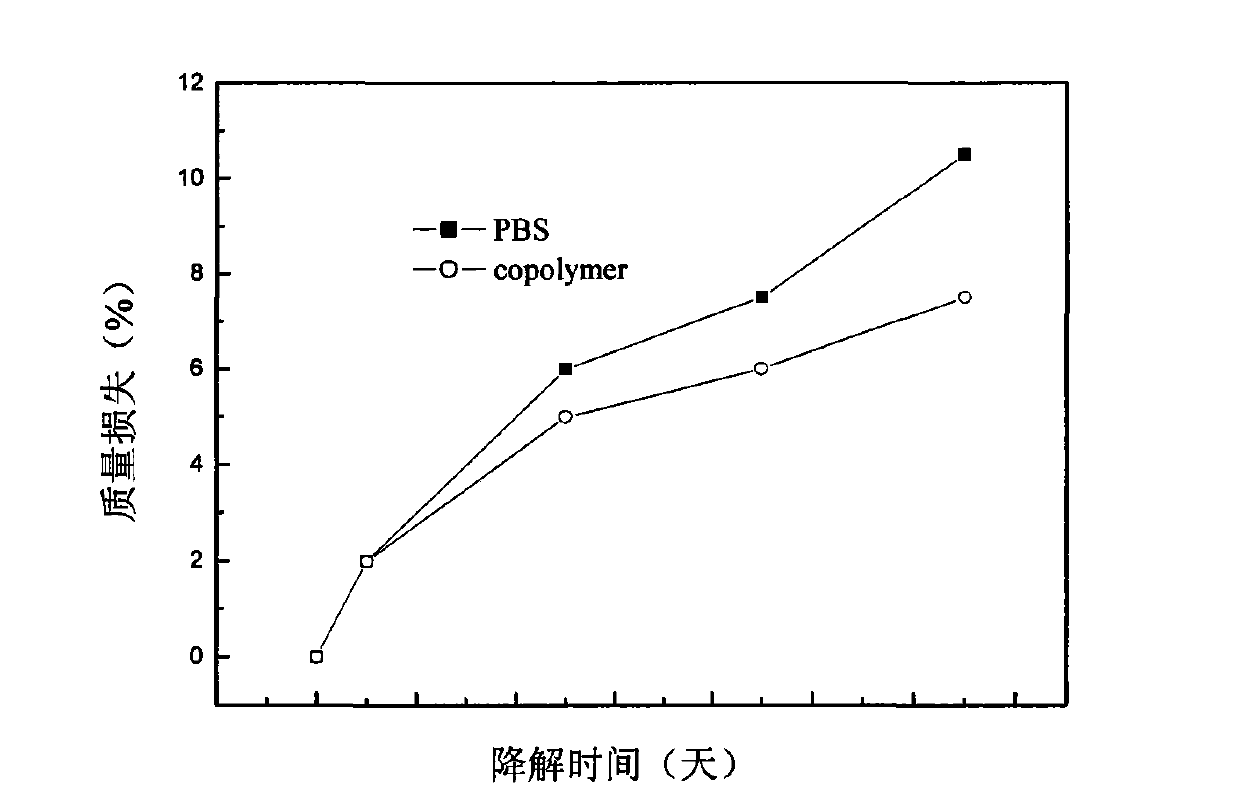

[0048] Embodiment 1, preparation high-performance biodegradable aliphatic polyester / aromatic polyester multi-block copolymer (PBS-b-PPT)

[0049] This embodiment prepares the method for high-performance biodegradable aliphatic polyester / aromatic polyester multi-block copolymer to comprise the steps:

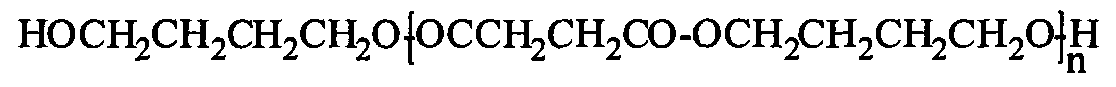

[0050] 1) Preparation of hydroxyl-terminated crystalline prepolymer A

[0051] At room temperature, 2500 g of succinic acid and 1,4-butanediol in a molar ratio of 1:1.5, and 2 g of isopropyl titanate were first added to a 5 L reaction kettle replaced with high-purity nitrogen. At the same time, the reactor is equipped with a high-purity nitrogen inlet, a mechanical stirrer, and a condenser. The above reaction system was controlled at 170°C, stirred and reacted with nitrogen gas until the water yield reached 95% of the theoretical water yield, then the temperature was raised to 230°C, the pressure was slowly lowered to 50 Pa, and polycondensation was continued for 9 hours. Obtai...

Embodiment 2

[0063] Embodiment 2, preparation high-performance biodegradable aliphatic polyester / aromatic polyester multi-block copolymer

[0064] 1) Preparation of hydroxyl-terminated crystalline prepolymer 1

[0065] At room temperature, 2500 g of adipic acid and 1,4-butanediol in a molar ratio of 1:2.8, and 1.5 g of butyl titanate were added to a 5 L reaction kettle replaced with high-purity nitrogen. At the same time, the reactor is equipped with a high-purity nitrogen inlet, a mechanical stirrer, and a condenser. The above reaction system was controlled at 180°C, stirred and reacted with nitrogen gas until the water yield reached 90% of the theoretical water yield, then the temperature was raised to 250°C, the pressure was slowly lowered to 5Pa, and then polycondensed for 3 hours. The obtained prepolymer A had a hydroxyl value of 106.74, an acid value of 3.46 and a number average molecular weight of 1,000.

[0066] 2) Preparation of rigid amorphous prepolymer B terminated by hydroxy...

Embodiment 3

[0070] Embodiment 3, preparation high-performance biodegradable aliphatic polyester / aromatic polyester multi-block copolymer

[0071] The prepolymer prepared in step 1) and step 2) of Example 2 was dried at 100° C. for 3 hours. The prepolymer A, prepolymer B, HDI according to the molar ratio of 8:1:17, a total of 1000g, 1500mL DMF and 25g of stannous octoate were sequentially added to the 5L reactor replaced by high-purity nitrogen. The above reaction system was heated to 200°C for 3 hours, and an excess of cold methanol was added to the obtained polymer solution. Obtain the biodegradable polyester-polyester block copolymer provided by the present invention through separation and drying, its number average molecular weight is 249,600, molecular weight distribution is 3.2, tensile strength is 43MPa, elongation at break is 190%, impact strength It is 160J / m.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Impact strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com