Method for preparing all-solid-state polymer electrolyte membrane and prepared electrolyte membrane

A technology of all-solid polymer and electrolyte membrane, which is applied in fuel cell components, circuits, fuel cells, etc., can solve problems such as electrolyte leakage and safety, and achieve increased compatibility, improved mechanical properties, and good ion conductivity rate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

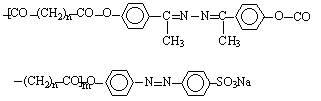

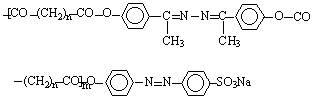

[0034] (1) Dissolve liquid crystal polymer E containing sulfonate ions at a concentration of 3 g / L in N-methylpyrrolidone and acetonitrile, and stir at a constant temperature of 75°C until completely dissolved to obtain solution G;

[0035] (2) Dissolve PEO with a concentration of 10 g / L (molecular weight of 500,000-600,000) in water and acetonitrile and stir until completely dissolved to obtain solution H;

[0036] (3) PMMA with a concentration of 10g / L (viscosity average molecular weight of 100,000-500,000) and LiClO with a concentration of 9g / L 4 Dissolve in acetone solution and stir until completely dissolved to obtain solution I;

[0037] (4) Mix the three solutions of G, H, and I at a volume ratio of 5:1:6. The viscosity after mixing is 10-300dl / g. Stir the mixture evenly, cast it in a polytetrafluoroethylene mold, and dry it in dry air. Volatile for 12 hours under the same conditions to form a film or use a spin coating mechanism to form a film, and then vacuum dry at ...

Embodiment 2

[0039] (1) Dissolve liquid crystal polymer F containing sulfonate ions at a concentration of 50 g / L in N-methylpyrrolidone and acetonitrile, stir at 80°C until completely dissolved, and obtain solution G;

[0040] (2) Dissolve PEO (with a molecular weight of 500,000-600,000) with a concentration of 20 g / L in water and acetonitrile and stir until completely dissolved to obtain solution H;

[0041] (3) PMMA with a concentration of 13g / L (viscosity average molecular weight of 100,000-500,000) and LiClO with a concentration of 10g / L 4 Dissolve in acetone solution and stir until completely dissolved to obtain solution I;

[0042] (4) Mix the three solutions of G, H, and I at a volume ratio of 5:1:6. The viscosity after mixing is 10-300dl / g. Stir the mixture evenly, cast it in a polytetrafluoroethylene mold, and dry it in dry air. Volatile under the conditions for 12h to form a film or use a spin coating mechanism to form a film, and then vacuum dry at 80°C for 72h to obtain a liqu...

Embodiment 3

[0044] (1) Dissolve liquid crystal polymer E containing sulfonate ions at a concentration of 25 g / L in N-methylpyrrolidone and acetonitrile, and stir at a constant temperature of 75°C until completely dissolved to obtain solution G;

[0045] (2) Dissolve PEO (molecular weight: 500,000-600,000) with a concentration of 15 g / L in water and acetonitrile and stir until completely dissolved to obtain solution H;

[0046] (3) PMMA with a concentration of 10g / L (viscosity average molecular weight of 100,000-500,000) and LiClO with a concentration of 10g / L 4 Dissolve in acetone solution and stir until completely dissolved to obtain solution I;

[0047] (4) Mix the three solutions of G, H, and I at a volume ratio of 5:1:6. The viscosity after mixing is 10-300dl / g. Stir the mixture evenly, cast it in a polytetrafluoroethylene mold, and dry it in dry air. Volatile under the conditions for 12h to form a film or use a spin coating mechanism to form a film, and then vacuum dry at 80°C for 7...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com