Conductive poly 3,4-ethylene dioxy thiophene film and preparation method thereof

A technology of ethylenedioxythiophene and conductive polymerization, which is applied in the direction of electrolytic components, electrolytic process, electrolytic organic production, etc., can solve the problems of unfavorable product separation, unsuitable for large-scale production, human body and environmental hazards, and achieve convenient polymerization speed Effects of regulation, ease of separation and purification, and improved polymerization efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1 carries out electrochemical polymerization at the liquid-liquid interface formed by dichloromethane and water

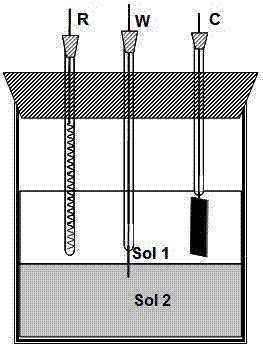

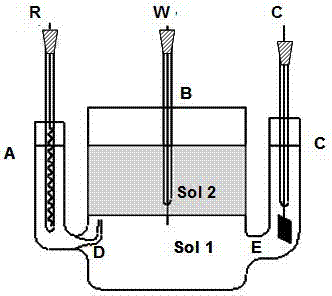

[0026] First take a certain amount of monomer ethylenedioxythiophene (EDOT) and supporting electrolyte lithium perchlorate (LiClO 4 ) were dissolved in the organic solvent chloroform and water respectively to prepare 0.01 mol / L EDOT chloroform solution and 0.1 mol / L LiClO 4 aqueous solution; sequentially take a certain volume of EDOT chloroform solution and LiClO 4 aqueous solution in figure 1 In the single-port polymerization device shown, a clear liquid-liquid interface is formed; then a certain length of platinum wire working electrode (0.5 mm in diameter) is vertically and slowly inserted into the liquid-liquid interface, and the platinum wire is ensured to slightly exceed the liquid-liquid interface and penetrate deep into the liquid-liquid interface. The oil phase is about 0.5 mm, and the platinum auxiliary electrode and saturated calomel ...

Embodiment 1 and comparative example 1

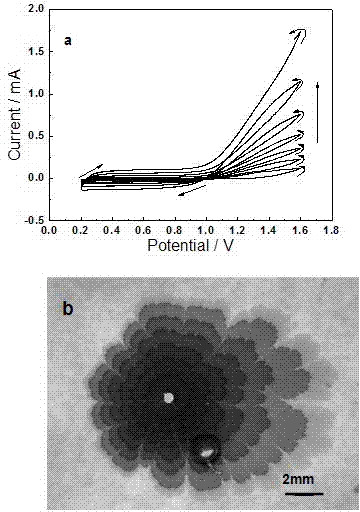

[0030] Embodiment 1 is in 0.01 mol / L EDOT trichloromethane solution and 0.1 mol / L LiClO 4 The liquid-liquid interface formed by the aqueous solution, in comparative example 1, was polymerized by cyclic voltammetry in 0.01 mol / L EDOT aqueous solution, the potential range: 0.2 V ~ 1.6 V, and the scanning speed: 20 mV / s. The cyclic voltammetry curve in the polymerization process of embodiment 1 and the macroscopic appearance of the conductive polymer film of generation see respectively image 3 a, b, the ring voltammetry curve of comparative example 1 polymerization process sees Figure 4 (The arrows in the figure indicate the direction and trend of current change).

[0031] Compared image 3 a and Figure 4It can be clearly seen that the cyclic voltammetry curve of the process of preparing the conductive polymer in the present invention shows a very different behavior from that of the polymerization in the traditional homogeneous system, especially in the oxidation potential ...

Embodiment 2

[0033] First take a certain amount of monomer ethylenedioxythiophene (EDOT) and supporting electrolyte perchloric acid (HClO 4 ) were dissolved in organic solvent dichloroethane and water respectively, and made into 1 mol / L EDOT dichloroethane solution and 2 mol / L HClO 4 aqueous solution; sequentially take a certain volume of EDOT dichloroethane solution and HClO 4 aqueous solution in figure 1 In the single-port polymerization device shown, a clear liquid-liquid interface is formed; then a certain length of platinum wire working electrode (0.5 mm in diameter) is vertically and slowly inserted into the liquid-liquid interface, and the platinum wire is ensured to slightly exceed the liquid-liquid interface and penetrate deep into the liquid-liquid interface. The oil phase is about 0.5 mm, and the platinum auxiliary electrode and saturated calomel (SCE) reference electrode are inserted into the upper layer of HClO 4 In aqueous solution; using a constant potential of 1.4V ( vs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com