Batch continuous production mode of fatty acid methyl ester transesterification reaction

A fatty acid methyl ester and transesterification technology, which is applied in fatty acid esterification, petroleum industry, biofuels, etc., can solve the problem of inability to achieve continuous batch operation at the same time, unable to effectively achieve the best yield, and not in line with economic benefits To achieve the effect of shortening the waiting time of operations, enhancing market competitiveness and prolonging the standing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

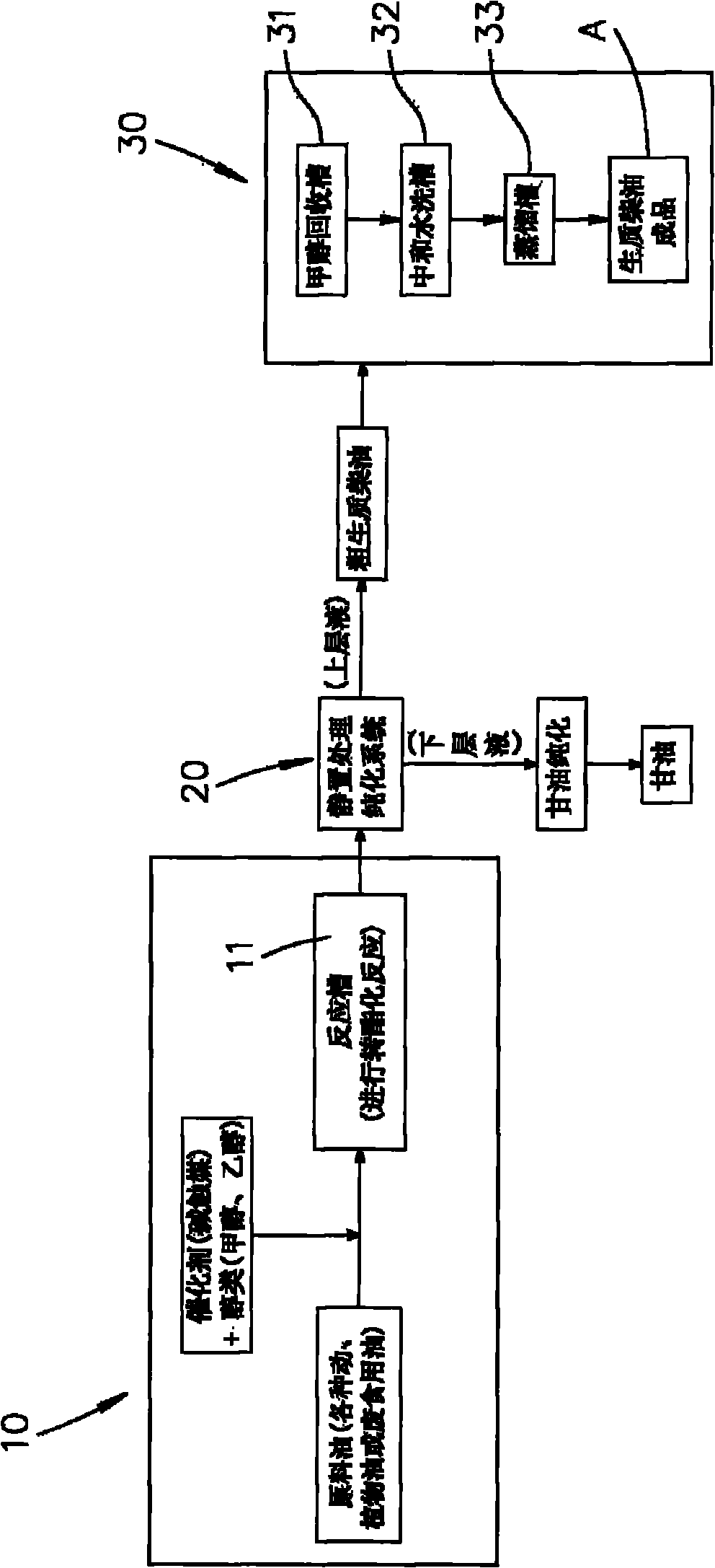

[0014] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings.

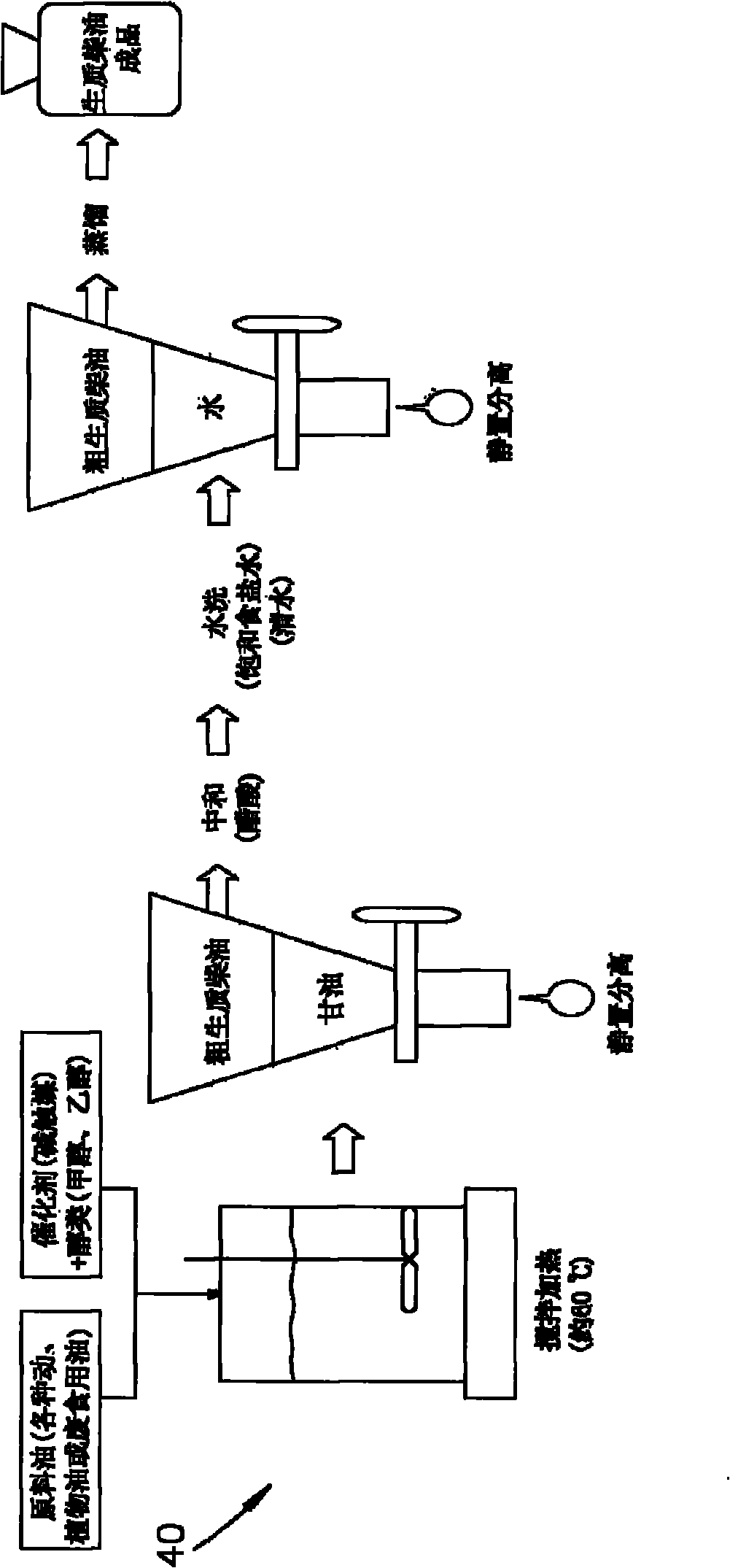

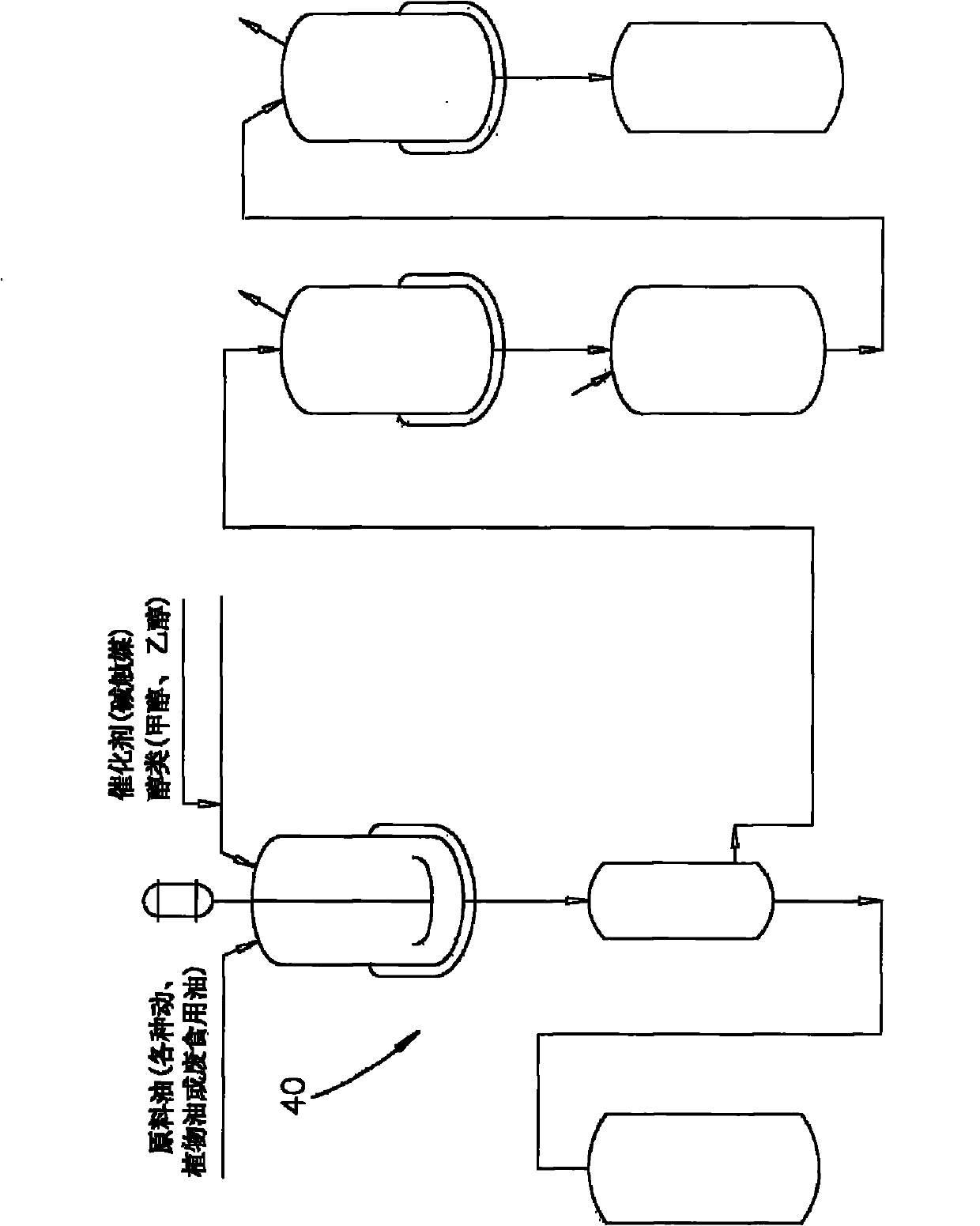

[0015] Such as image 3 Shown is the production flow chart of fatty acid methyl ester (biodiesel) of the present invention, and the preparation method of its biodiesel mainly consists of a feed oil (such as various animal and vegetable oils or waste cooking oil), alcohol The materials of class (such as methanol, ethanol) and catalyst (such as alkali catalyst), through a pretreatment procedure 10 phase transesterification reaction of a reaction tank 11, and cooperate with a static treatment purification system 20 (such as Figure 4 Shown), for the pretreatment program 10, the reaction product of the transesterification reaction in the reaction tank 11 can continue to be purified, and is output to a follow-up purification program of a methanol recovery tank 31, a neutralization washing tank 32 and a distillation tank 33 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com