Hydrophobic inorganic fine particle and toner

An inorganic fine particle, hydrophobic technology, applied in the direction of developer, transportation and packaging, dyeing organosilicon compound treatment, etc., can solve the problems of toner fluidity and charging performance reduction, image quality deterioration, silicone oil is difficult to penetrate, etc., Achieve the effects of excellent charging performance, excellent fluidity and excellent durability

Active Publication Date: 2011-04-20

CANON KK

View PDF5 Cites 21 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0005] However, the hydrophobic groups introduced to the surface of inorganic fine particles by such treatment agents have a large molecular size, and the hydrophobic groups cannot reach adjacent hydroxyl groups due to steric hindrance.

As a result, the hydroxyl groups remain unreacted, whereby hydrophobization is not performed, so sufficient hydrophobicity cannot be imparted to inorganic fine particles in some cases

[0006] In addition, because silicone oil has a relatively high molecular weight and high viscosity, it is difficult to uniformly use silicone oil for surface treatment of the surface of inorganic fine particles

[0007] In particular, when the toner is stored in a high-temperature, high-humidity environment for a long time before use, external addition of inorganic fine particles that have not been sufficiently hydrophobized to the toner may involve a problem that since the inorganic fine particles absorb moisture, The fluidity and charging performance of the toner are lowered, and thus the quality of an image formed from the toner is deteriorated

However, most of the silicone oil is not fixed on the surface of the silica in the process, so there is a problem in some cases that when the toner is stored in a high-temperature, high-humidity environment with the silica externally added to the toner, the adjustment The toner tends to absorb moisture, so that it inhibits its charging

However, the amount of free silicone oil that is not fixed on the surface of the silica particles becomes extremely small, so problems such as contamination of the contact charging member due to adhesion of the silica powder to the member or conditioning of the silica powder containing The toner is melt-adhered to the photosensitive member

[0014] In this method, the abundance of free silicone oil on the surface of silica can be controlled, but because its molecular weight is greater than that of reaction treatment agents such as dimethyldichlorosilane or hexamethyldisilazane, it is difficult for silicone oil to penetrate into the silica Microscopic unevenness on the silicon surface

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1 to 8

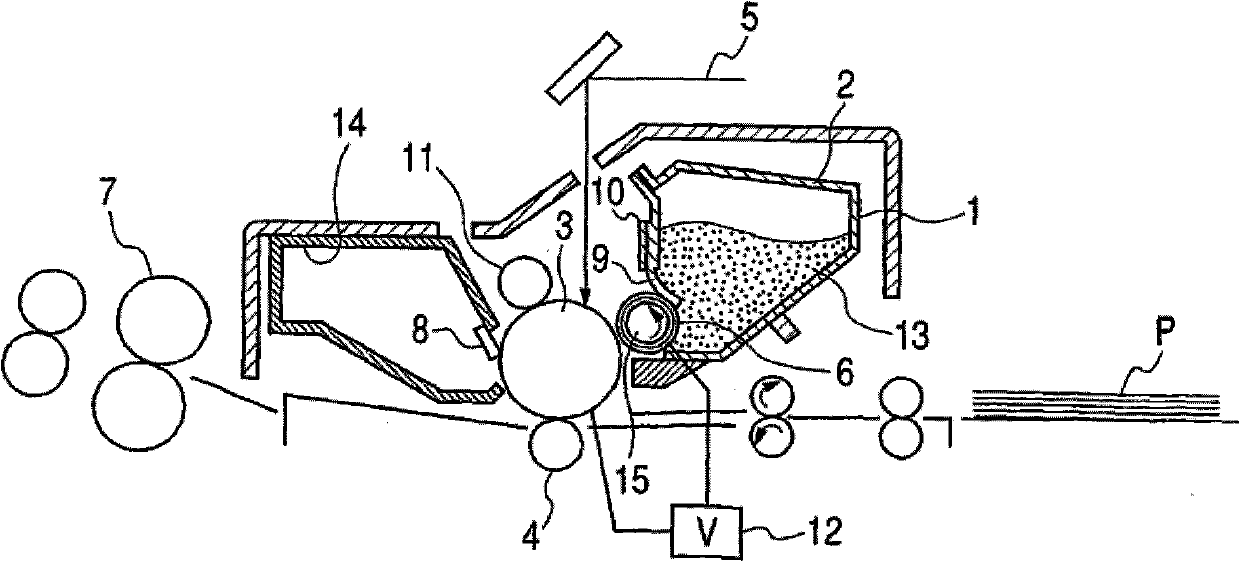

[0339] 1.0 part by mass of any one of the hydrophobic inorganic fine particles 1 to 8 was externally added to 100 parts by mass of the magnetic toner particles, mixed by means of a Henschel mixer, whereby toners 1 to 8 were obtained.

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| wettability | aaaaa | aaaaa |

Login to View More

Abstract

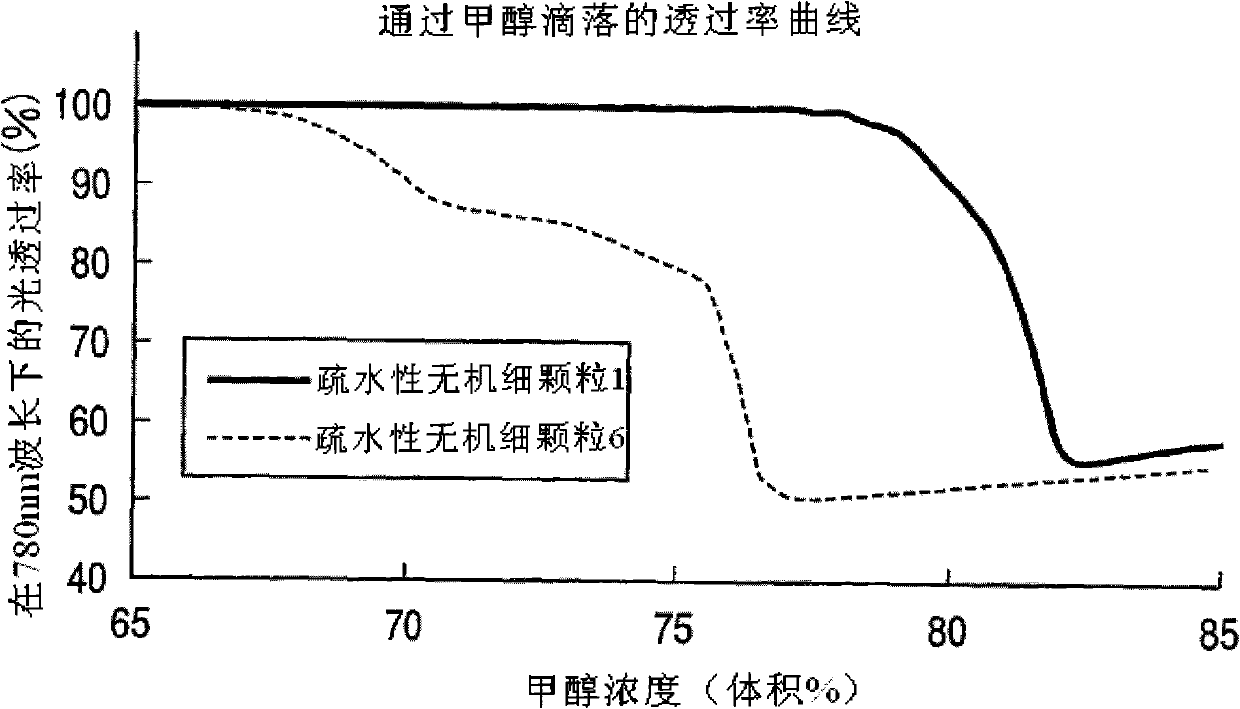

Hydrophobic inorganic fine particles are provided which prevent a toner from fusing to a photoreceptor or fouling a contact charging member and which enable the toner to be excellent in flowability, electrification characteristics, and durability even after long-term storage in a high-temperature high-humidity atmosphere. The fine particles prevent the toner from dropping or fouling the inside ofthe printer. The hydrophobic inorganic fine particles are obtained by: treating the surface of inorganic fine particles with a silicone oil and then with a silane compound and / or a silazane compound or treating the surface of inorganic fine particles with a silane compound and / or a silazane compound in the presence of a silicone oil; and further treating the treated inorganic fine particles with a silicone oil.

Description

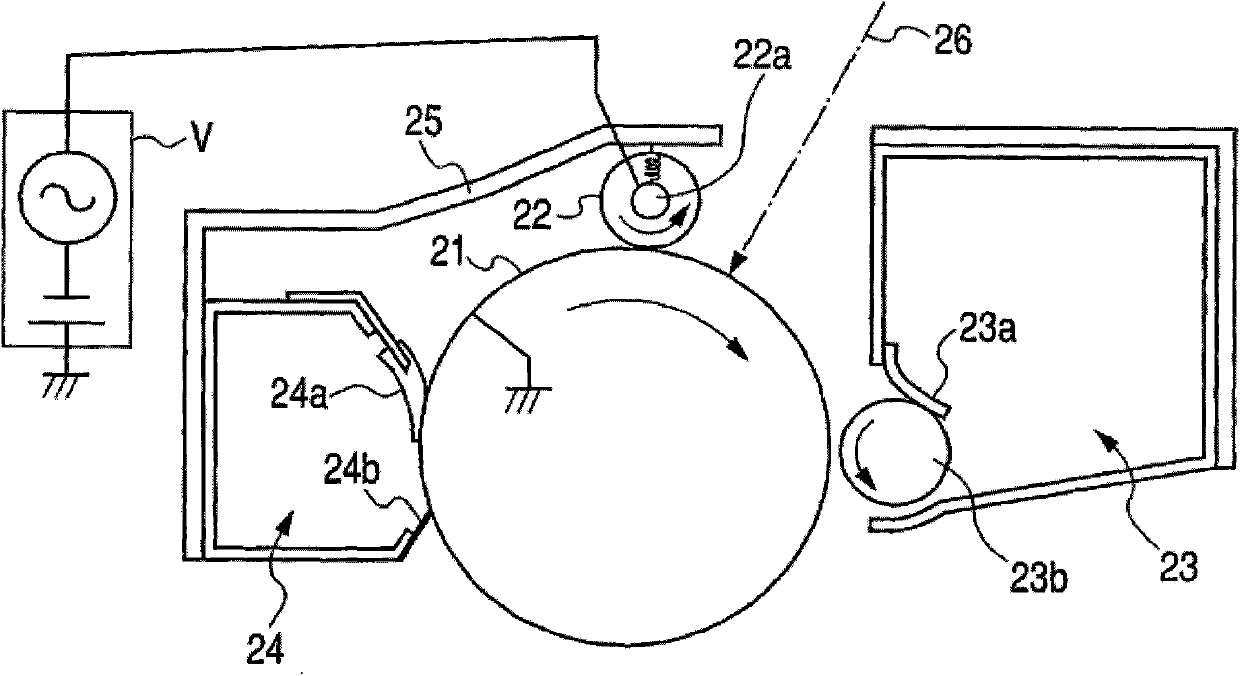

technical field [0001] The present invention relates to hydrophobic inorganic fine particles used in image forming methods such as electrophotography, electrostatic printing, or toner jetting, and toners containing the hydrophobic inorganic fine particles. Background technique [0002] It is generally known to externally add inorganic fine particles to toner particles for the purpose of adjusting charging performance, fluidity, and the like of toner so that good developability can be obtained. Wet-process silica, dry-process silica, titanium oxide, alumina, etc. are conventionally used as the hydrophobic fine inorganic particles, and it has been proposed to subject the fine inorganic particles to a hydrophobizing treatment in order that the environmental stability of toner charging can be improved. [0003] Surface treatment with, for example, a silane compound, a silazane compound, or silicone oil is performed as hydrophobization treatment for these inorganic fine particles...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C01B13/14C01B33/18C01G23/04G03G9/08

CPCC01P2006/12C09C1/3072C09C1/3081G03G9/09716G03G9/09725C01P2004/64C09C3/12C01P2004/62B82Y30/00Y10T428/2995

Inventor 小川吉宽长谷川雄介西川浩司冈崎美穗铃村祯崇粕谷贵重

Owner CANON KK

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com