Preparation method of high-purity zinc powder

A zinc powder and high-purity technology, which is applied in the field of preparation of high-purity zinc powder, can solve the problems of coal-burning environmental pollution, large fluctuations in furnace temperature, and unstable calorific value of gas, and achieve the effect of high purity and high combustion efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

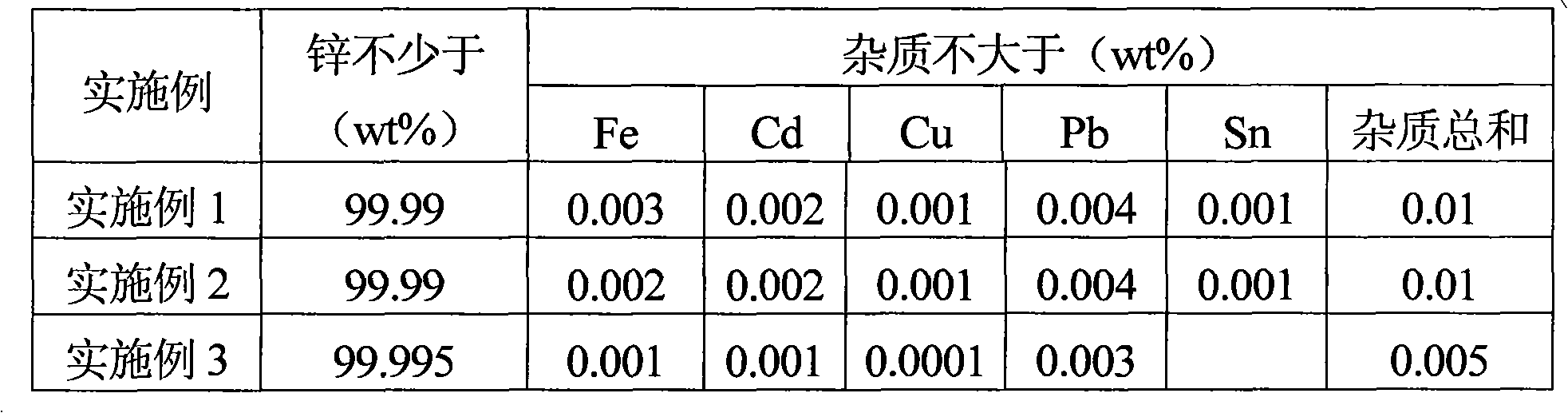

Embodiment 1

[0020] Turn on the natural gas heating source, preheat the zinc melting furnace, raise the furnace temperature to 450°C, put in zinc ingots, and continue heating the zinc melting furnace. When the furnace temperature rises to about 520°C, the zinc ingots will melt into zinc Water; then lead the zinc water into the reverberatory furnace, turn on the natural gas heating source, control the temperature of the molten pool at about 500°C, and let it stand for 24 hours to achieve the stratification of the melt, and the upper layer is the refined zinc from the melt; remove the floating water on the surface of the molten pool slag; put the melt refined zinc obtained by layering into the lead tower holding furnace for preservation, the temperature is controlled at 630°C, and keep warm for 5 hours; then the melt refined zinc is introduced into the lead tower, and the temperature of the lead tower combustion chamber is controlled at about 1200°C , so that the zinc and cadmium in it are se...

Embodiment 2

[0022] Turn on the natural gas heating source, preheat the zinc melting furnace, raise the furnace temperature to 500°C, put in zinc ingots, and continue heating the zinc melting furnace. When the furnace temperature rises to about 580°C, the zinc ingots will melt into zinc water; then lead the zinc water into the reverberatory furnace, turn on the natural gas heating source, control the temperature of the molten pool at about 460°C, and let it stand for 36 hours to achieve the stratification of the melt, and the upper layer is the refined zinc from the melt; remove the floating water on the surface of the molten pool slag; put the melted refined zinc obtained by layering into the lead tower holding furnace for preservation, the temperature is controlled at 600°C, and keep warm for 4 hours; then the melted refined zinc is introduced into the lead tower, and the temperature of the lead tower combustion chamber is about 1100°C. The zinc and cadmium in it are separated from the hi...

Embodiment 3

[0024] Turn on the natural gas heating source, preheat the zinc melting furnace, raise the furnace temperature to 480°C, put in zinc ingots, and continue heating the zinc melting furnace. When the furnace temperature rises to about 550°C, the zinc ingots will melt into zinc Then lead the zinc water into the refining furnace, turn on the natural gas heating source, control the temperature of the molten pool at about 480°C, and let it stand for 30 hours to achieve the stratification of the melt, and the upper layer is the refined zinc from the melt; remove the floating slag; put the melt refined zinc obtained by layering into the lead tower holding furnace for preservation, the temperature is controlled at 580°C, and keep warm for 3 hours; then the melt refined zinc is introduced into the lead tower, and the temperature of the lead tower combustion chamber is about 1150°C. The zinc and cadmium in it are separated from the high boiling point impurities lead and iron; the zinc and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com