Power system for mechanical-electrical-liquid hybrid-driven vehicle and control method thereof

A hybrid drive and vehicle power technology, applied in the field of hybrid drive vehicle transmission system, can solve the problems of increasing battery and motor load and impact, shortening the mileage of electric vehicles, reducing the service life of batteries, etc., so as to improve power performance and improve work Performance and service life, effect of prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

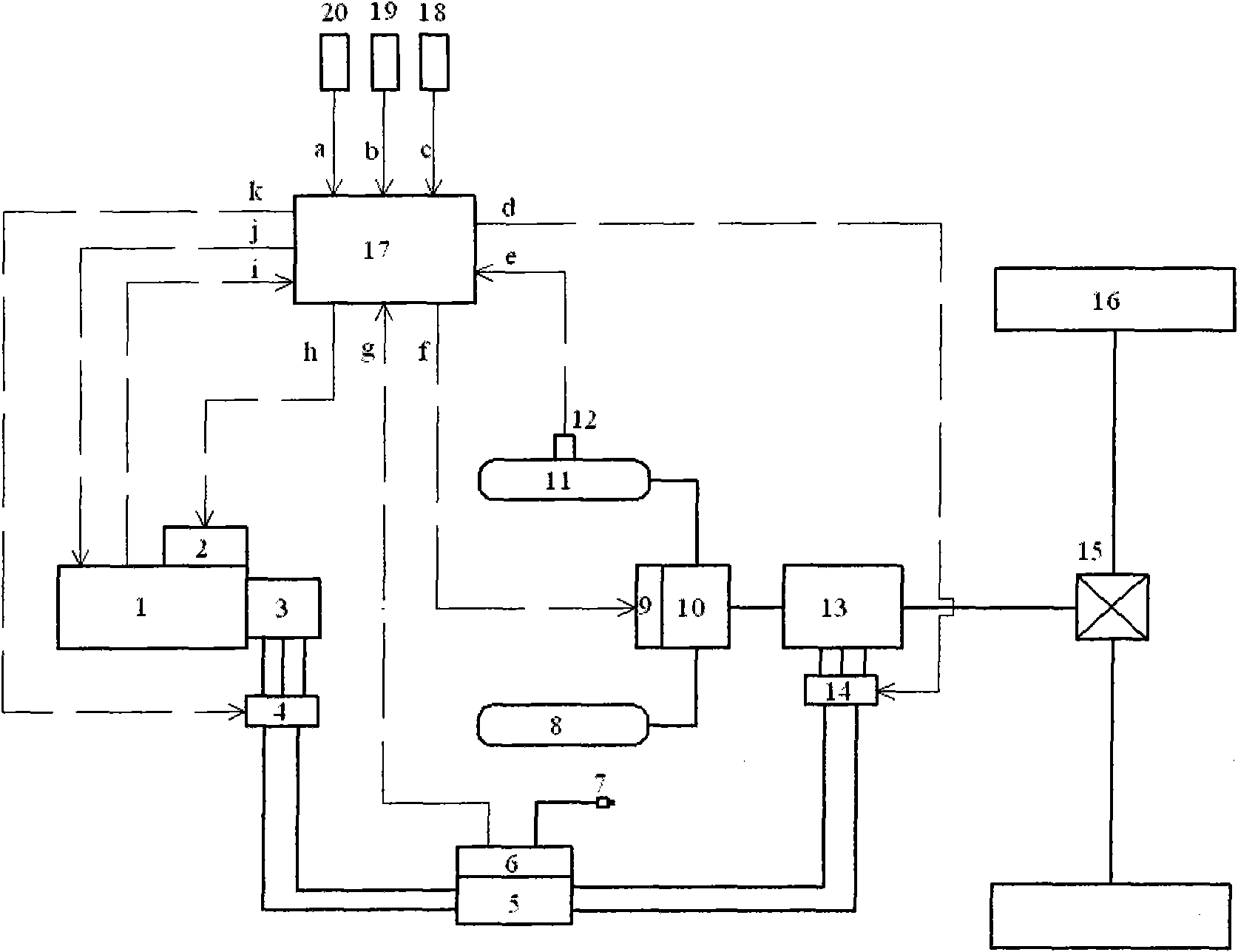

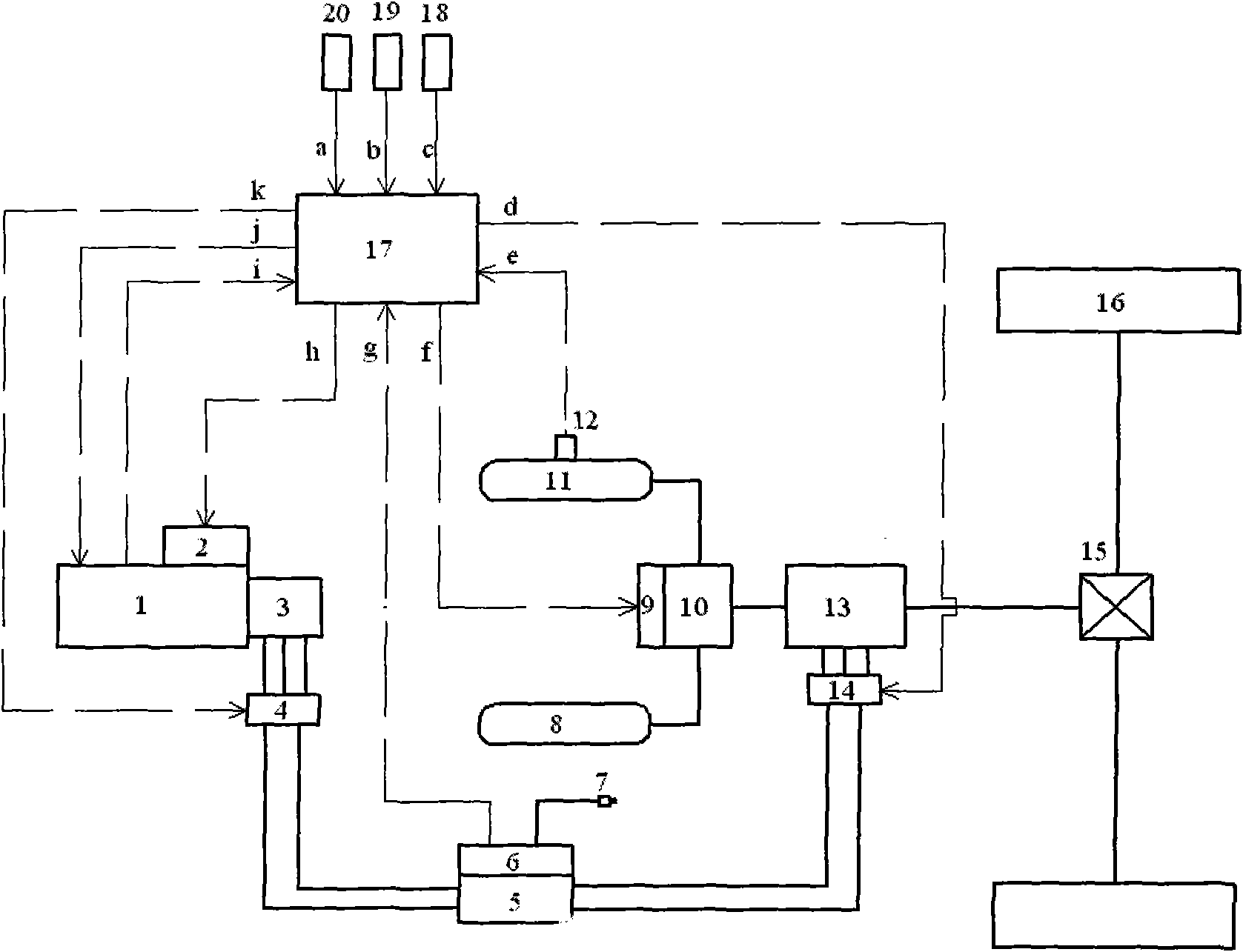

[0017] refer to figure 1 , internal combustion engine 1, internal combustion engine control unit 2, generator 3, generator control unit 4, battery 5, battery energy management unit 6, external charging interface 7, low-voltage accumulator 8, pump / motor variable mechanism 9, hydraulic pump / motor 10. High-pressure accumulator 11, pressure sensor 12, motor 13, motor control unit 14, main reducer and differential 15, drive wheel 16, system control unit 17, vehicle speed sensor 18, brake pedal position sensor 19, accelerator pedal Position sensor 20, accelerator pedal position signal a from accelerator pedal position sensor 20, brake pedal position signal b from brake pedal position sensor 19, vehicle speed signal c from vehicle speed sensor 18, motor control signal d, pressure sensor 12 The high-pressure accumulator pressure signal e, the variable control signal f of the hydraulic pump / motor 10, the battery status signal g from the battery energy management unit 6, the trigger sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com