Method for decyanating coking wastewater

A coking wastewater and decyanation technology, which is applied in chemical instruments and methods, water/sewage treatment, water/sewage multi-stage treatment, etc., can solve the problems that affect the cyanide in wastewater and the removal of pollutants such as COD, and reduce the Load, less investment, simple operation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

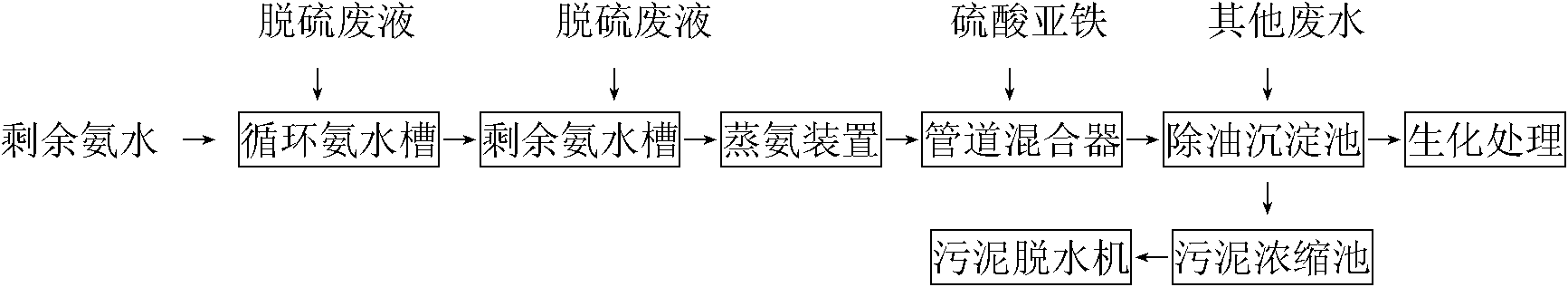

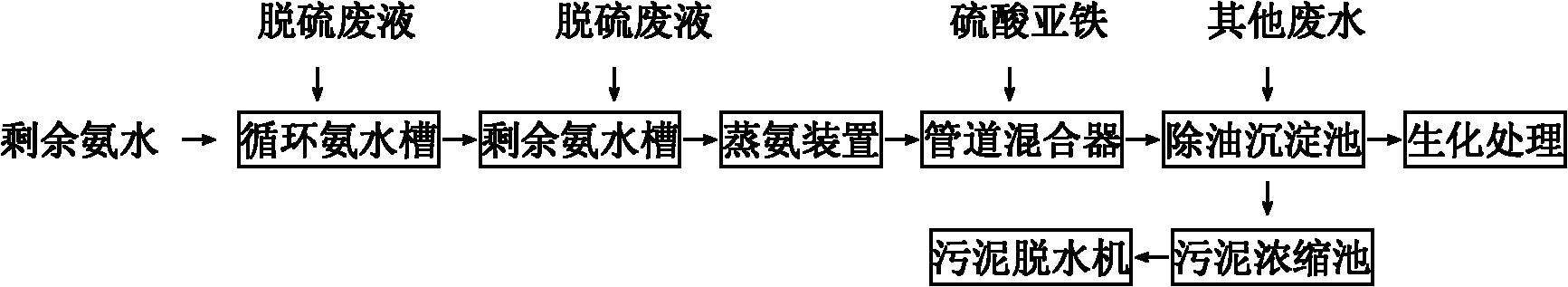

[0020] A method for decyanation of coking wastewater, which is used for decyanation of coking wastewater desulfurized by vacuum potassium carbonate method. The method uses ferrous sulfate complex decyanation to reduce the total cyanide content in raw sewage and reduce its impact on biochemical treatment. Lay the foundation for cyanide compliance. Its reaction principle is as following equation:

[0021] FeSO 4 +6KCN→K 4 Fe(CN) 6 +K 2 SO 4

[0022] 3K 4 Fe(CN) 6 +2Fe 2 (SO 4 ) 3 → Fe 4 [Fe(CN) 6 ] 3 ↓(Prussian blue)+6K 2 SO 4

[0023] Cyanide ions react with ferrous ions and iron ions to form water-insoluble ferrocyanide blue precipitate (Prussian blue), and then separate the precipitate from coking wastewater, so that cyanide in coking wastewater can be removed. After decyanation pretreatment, the wastewater enters the biochemical treatment system. The total cyanide in the wastewater should be controlled below 15mg / l, and the cyanide should be controlled below...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com