Metal zinc coating blackening agent and preparation method thereof

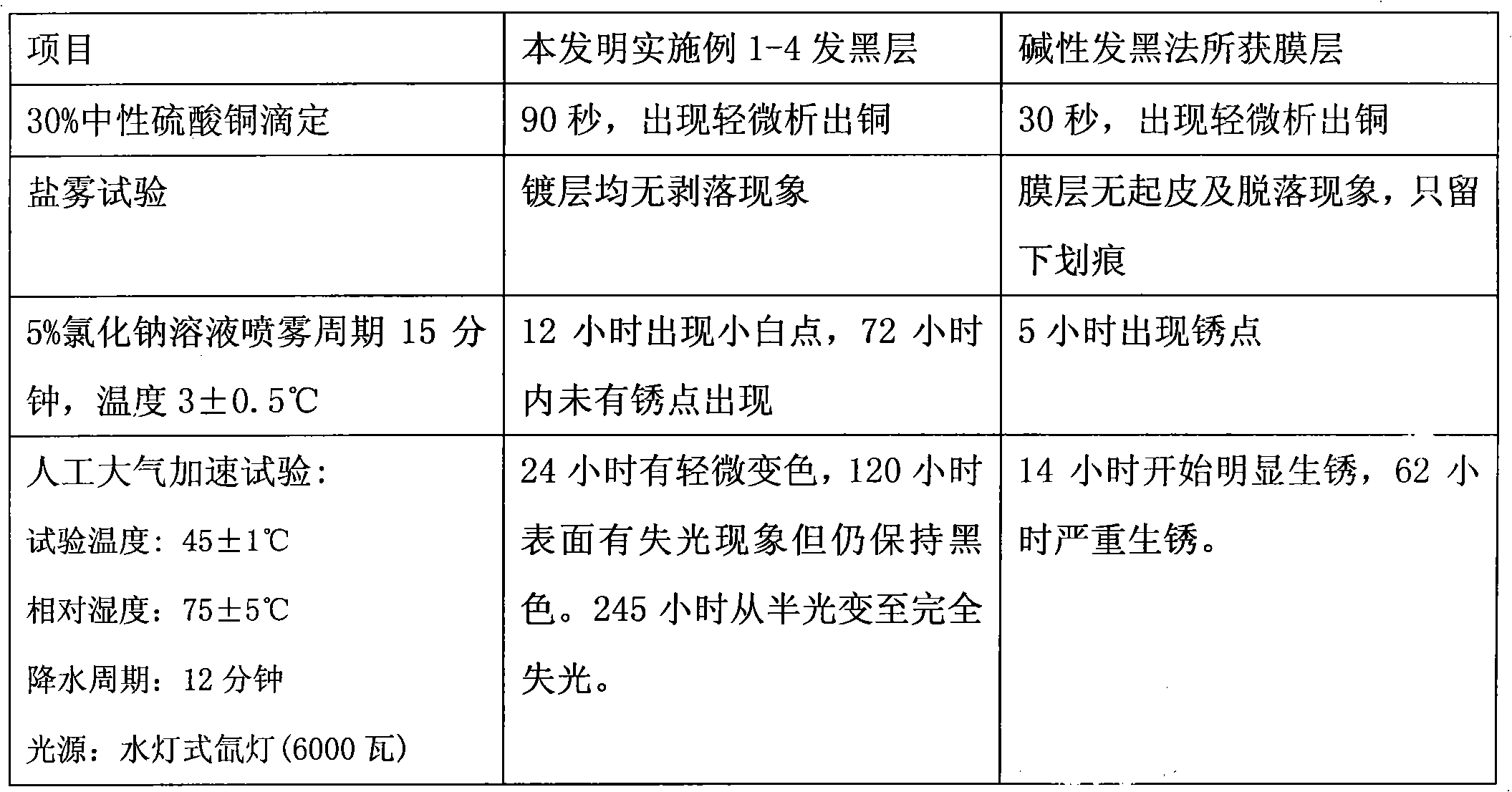

A technology of galvanized layer and blackening agent, which is applied in the coating process of metal materials, etc., can solve the problems of poor adhesion and wear resistance, high energy consumption, and high pretreatment requirements, and achieve good adhesion, simple process, and durability Corrosive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) Add 40 parts of water in the reaction vessel, then add 20 parts of the main film-forming substance ammonium molybdate and 0.7 part of copper sulfate, stir to make it dissolve completely, and prepare the semi-finished product treatment liquid;

[0027] (2) Add 2.5 parts of nickel sulfate, 1 part of sodium sulfite, 2.5 parts of sodium thiosulfate, 4 parts of aluminum chloride, 3.5 parts of zinc chloride, 7.5 parts of potassium chloride in step (1) semi-finished product treatment liquid again, stir to make It is completely dissolved to obtain a semi-finished product treatment liquid;

[0028] (3) add 0.3 part of complexing agent ascorbic acid in step (2) semi-finished product treatment liquid again, stir and make it dissolve completely, then adjust its pH value at 1.5 with acetic acid, both obtained blackening agent of the present invention.

Embodiment 2

[0030] (1) Add 60 parts of water in the reaction vessel, then add 25 parts of the main film-forming substance ammonium molybdate and 0.5 part of copper sulfate, stir to make it dissolve completely, and prepare the semi-finished product treatment liquid;

[0031] (2) Add 3 parts of nickel sulfate, 3 parts of sodium sulfite, 3.5 parts of sodium thiosulfate, 3.5 parts of aluminum chloride, 3 parts of zinc chloride, 8 parts of potassium chloride in step (1) semi-finished product treatment liquid again, stir to make It is completely dissolved to obtain a semi-finished product treatment liquid;

[0032] (3) Add 0.5 part of complexing agent citric acid in step (2) semi-finished product treatment liquid again, stir to all dissolvings, then adjust its pH value at 1.0 with acetic acid, both obtained blackening agent of the present invention.

Embodiment 3

[0034] (1) Add 50 parts of water in the reaction vessel, then add 22 parts of the main film-forming substance ammonium molybdate and 0.6 part of copper sulfate, stir to make it dissolve completely, and prepare the semi-finished product treatment liquid;

[0035] (2) Add 2 parts of nickel sulfate, 2 parts of sodium sulfite, 3 parts of sodium thiosulfate, 4.5 parts of aluminum chloride, 4 parts of zinc chloride, 7 parts of potassium chloride successively in step (1) semi-finished product treatment liquid, stir Dissolve it completely to obtain a semi-finished treatment solution;

[0036] (3) add 0.4 part of complexing agent Hydroquinone to step (2) semi-finished product treatment liquid again, stir to all dissolvings, then adjust its pH value at 1.2 with acetic acid, both obtained blackening agent of the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com