Corrosion inhibitor for preventing corrosion of oil-gas field steel equipment and preparation method thereof

A corrosion inhibitor, technology for oil and gas fields, applied in earth-moving drilling, wellbore/well components, etc., can solve problems such as worn rotors, and achieve the effects of improved polarization resistance, easy synthesis, and high corrosion inhibition rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0030] Example 1 is the synthesis and preparation of corrosion inhibitors and the evaluation of the corrosion inhibition performance of corrosion inhibitors by the laboratory hanging plate method. The laboratory coupon method is to prepare a corrosion solution in the laboratory to simulate the actual corrosion environment for corrosion coupon experiments. A3 steel (carbon structural steel) test pieces were selected for corrosion experiments, and the blank and corrosion inhibitor were used for comparison. According to the corrosion weight loss and corrosion status of the test pieces, the corrosion inhibition rate was calculated.

example 2

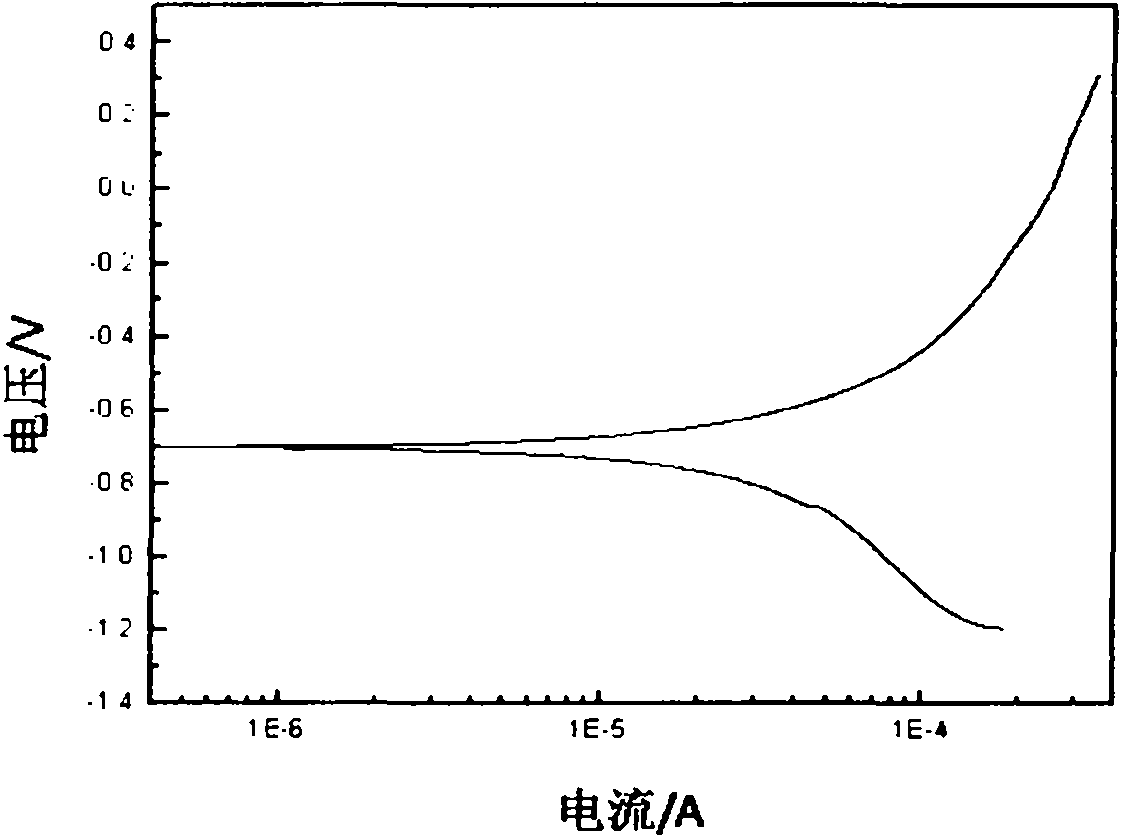

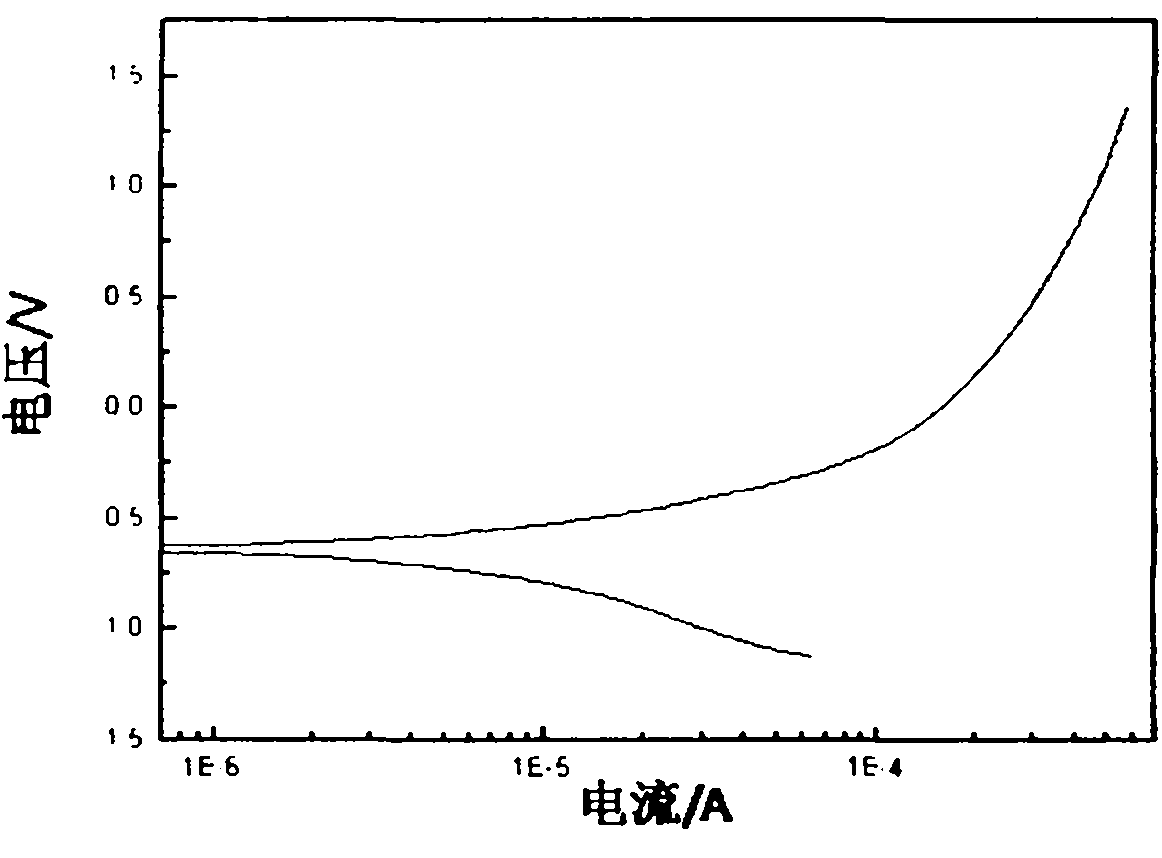

[0031] Example 2 is the evaluation of the corrosion inhibition performance of the corrosion inhibitor by electrochemical method. The three-electrode system of A3 steel sample-platinum electrode-saturated potassium chloride electric shock was used to measure its electrochemical behavior in saturated hydrogen sulfide aqueous solution with and without the addition of corrosion inhibitor.

example 3

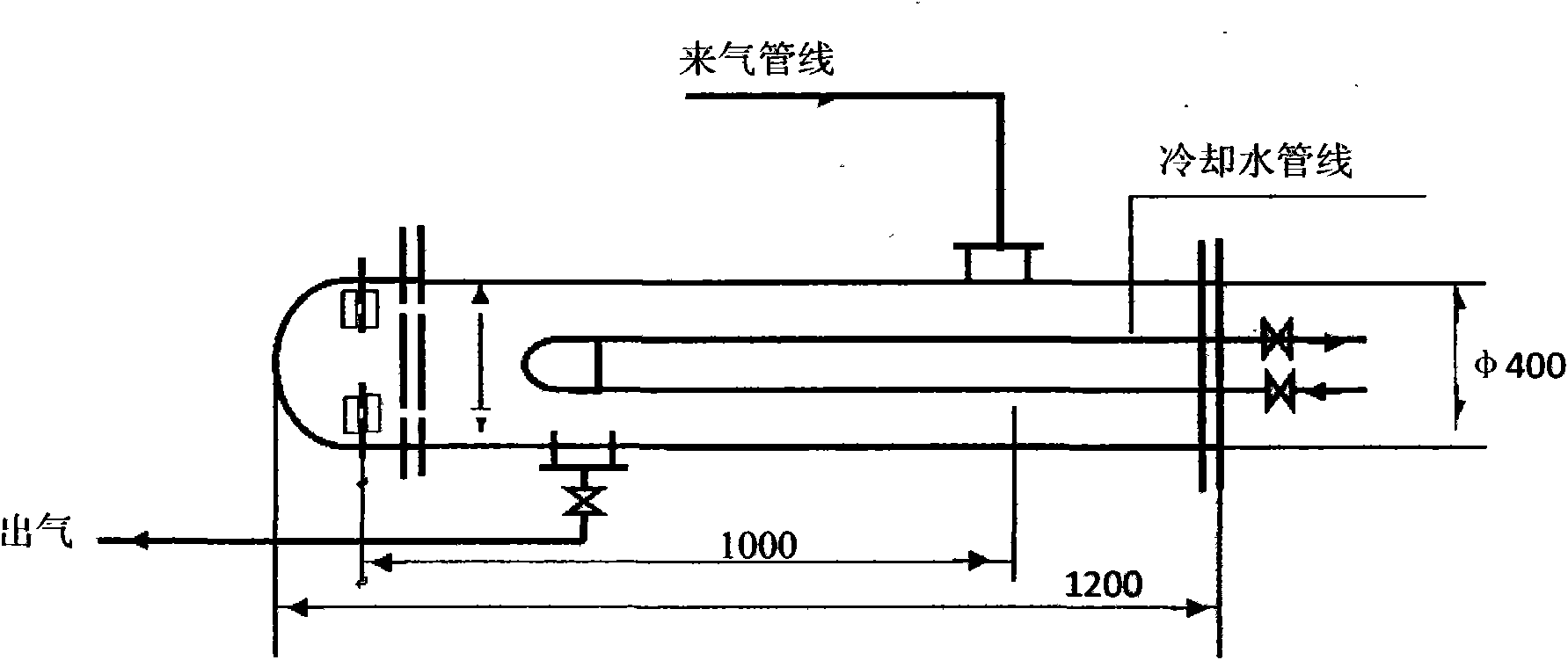

[0032] Example 3 is the synthesis and preparation of corrosion inhibitors and the evaluation of corrosion inhibition performance of corrosion inhibitors by on-site hanging method. The on-site coupon method is a corrosion coupon test carried out in a bypass device connected in parallel with a natural gas centrifuge. A3 steel (carbon structural steel) test pieces were selected for corrosion experiments, and the blank and corrosion inhibitors were used for comparison. According to the corrosion weight loss and corrosion status of the test pieces, the corrosion inhibition rate was calculated, and the microscopic shape of the surface of the hanging pieces was observed by scanning electron microscopy. appearance.

[0033] Example 1:

[0034] Proportion: crude quinoline base mixture 1kg

[0036] Monochlorooctane 0.5kg

[0037] Ethanol 4kg

[0038] Add potassium amide to the crude quinoline base mixture [its main components are methyl quinoline (abo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com