Impervious early strength organosilicon waterproof agent and preparation process thereof

A preparation process and technology of waterproofing agent, applied in the field of silicone waterproofing agent and preparation technology thereof, can solve the problems of difficulty in widespread use, poor impermeability, complicated construction, etc. simple craftsmanship

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

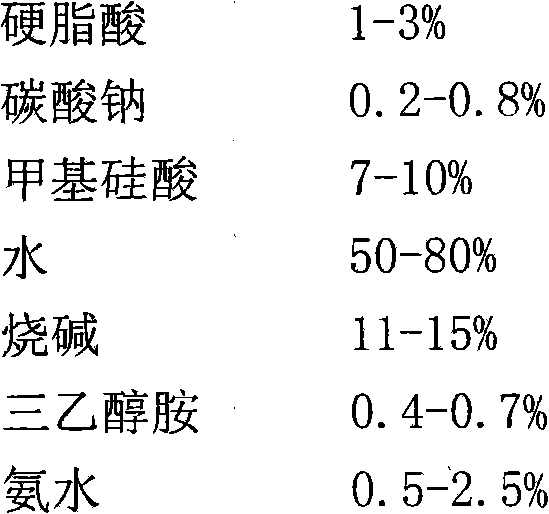

[0014] Embodiment 1 selects each raw material by following raw material and weight percentage proportioning

[0015]

[0016] The preparation process requirements are as follows:

[0017] Heat stearic acid, sodium carbonate, methyl silicic acid, water, and caustic soda in a reaction kettle at 80-95°C, stir for 2 hours, then add triethanolamine, ammonia water, and stir for 10 minutes, then use a 0.6mm mesh Filter through a sieve to remove lumps, and put the filtrate into a closed plastic bucket to obtain an impermeable early-strength silicone waterproofing agent.

Embodiment 2

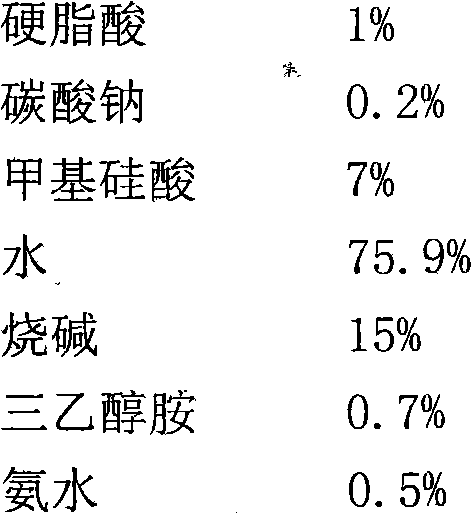

[0018] Embodiment 2 selects each raw material by following raw material and percentage by weight proportioning

[0019]

[0020] The preparation process requirements are as follows:

[0021] Heat stearic acid, sodium carbonate, methyl silicic acid, water, and caustic soda in a reaction kettle at 80-95°C, stir for 2 hours, then add triethanolamine, ammonia water, and stir for 10 minutes, then use a 0.6mm mesh Filter through a sieve to remove lumps, and put the filtrate into a closed plastic bucket to obtain an impermeable early-strength silicone waterproofing agent.

Embodiment 3

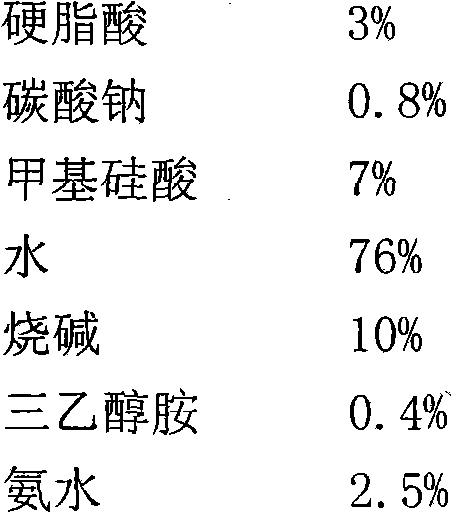

[0022] Embodiment 3 selects each raw material by following raw material and weight percentage proportioning

[0023]

[0024] The preparation process requirements are as follows:

[0025] Heat stearic acid, sodium carbonate, methyl silicic acid, water, and caustic soda in a reaction kettle at 80-95°C, stir for 2 hours, then add triethanolamine, ammonia water, and stir for 10 minutes, then use a 0.6mm mesh Filter through a sieve to remove lumps, and put the filtrate into a closed plastic bucket to obtain an impermeable early-strength silicone waterproofing agent.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com