Yellow wine production method with improved rice raw material treatment

A production method and technology for raw materials are applied in the field of rice wine production with improved raw rice processing technology, achieving the effects of comfortable and refreshing taste, high quality and reduced processing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

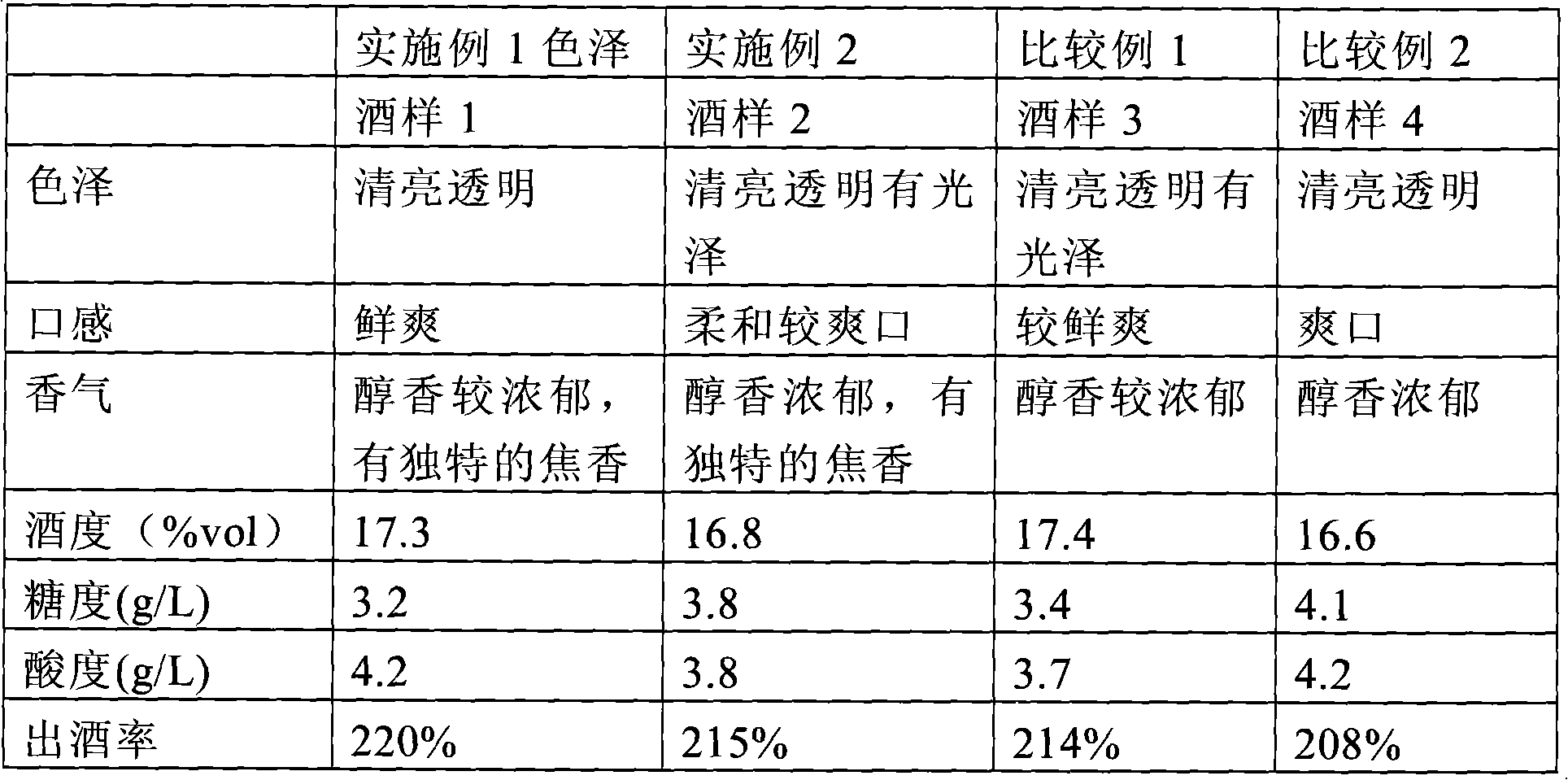

Examples

Embodiment 1

[0012] Roasting of Raw Rice

[0013] The raw material rice used is japonica rice, and the rice is transported to a roasting machine with a roasting temperature of 140°C, a roasting time of 45 min, and a steam pressure of 0.4 MPa, and is naturally cooled to room temperature.

[0014] absorb water

[0015] The baked rice is lifted to the rice collection hopper, and then the rice is evenly transported to the spraying circulation system through the conveyor belt, so that the rice can fully absorb water. The water absorption time is controlled at about 40 minutes, and the water absorption rate is controlled at 45-50%.

[0016] Pre-steam

[0017] The rice after fully absorbing water is conveyed to the rice steamer 1 through the conveyor belt. When steaming the rice, the height of the rice layer should be controlled to be about 30cm, the steam pressure should be 0.10-0.25Mpa, and the cooking time should be about 10min.

[0018] Secondary water absorption

[0019] After the ...

Embodiment 2

[0031] Roasting of Raw Rice

[0032] The rice used is glutinous rice, and the rice is transported to a roasting machine with a roasting temperature of 130°C, a roasting time of 35 minutes, and a steam pressure of 0.4 MPa, and is naturally cooled to room temperature.

[0033] absorb water

[0034] The baked rice is lifted to the rice collection hopper, and then the rice is evenly transported to the spraying circulation system through the conveyor belt, so that the rice can fully absorb water. The water absorption time is controlled at about 40 minutes, and the water absorption rate is controlled at 45-50%.

[0035] Pre-steam

[0036] The rice after fully absorbing water is transported to the rice steamer 1 through the conveyor belt. When steaming the rice, the height of the rice layer should be controlled to be about 30cm, the steam pressure should be 0.10-0.25Mpa, and the cooking time should be about 5min.

[0037] Secondary water absorption

[0038] After the rice s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com