Thermal analyzer for material pyrolysis behavior and flowing carrier gas-single-drop microextraction combined device and using method thereof

A thermal analyzer and material technology, which is applied in thermal analysis of materials, measuring devices, and analytical materials, etc., can solve the problems of difficulty in collecting escaping components from thermal analyzers, and difficulty in qualitative and semi-quantitative analysis of mixtures for escaping components. To achieve the effect of good extraction effect, convenient operation and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] Example 1: Using thermogravimetry-flowing carrier gas-single droplet microextraction device combined with gas chromatography-mass spectrometry to analyze the pyrolysis behavior of lutein

[0045] 1. Before the experiment, keep the thermogravimetric in the air atmosphere at 600°C for 10 minutes to remove impurities in the furnace. Accurately weigh 5.00±0.05mg of lutein and put it into a thermogravimetric platinum crucible. The heating program is The sensitivity of the thermobalance is 1 μg, the temperature control range of the furnace body is from room temperature to 1000 ° C, the carrier gas is air, the empty crucible is used as a reference object, and the flow rate of the carrier gas is 400 mL / min.

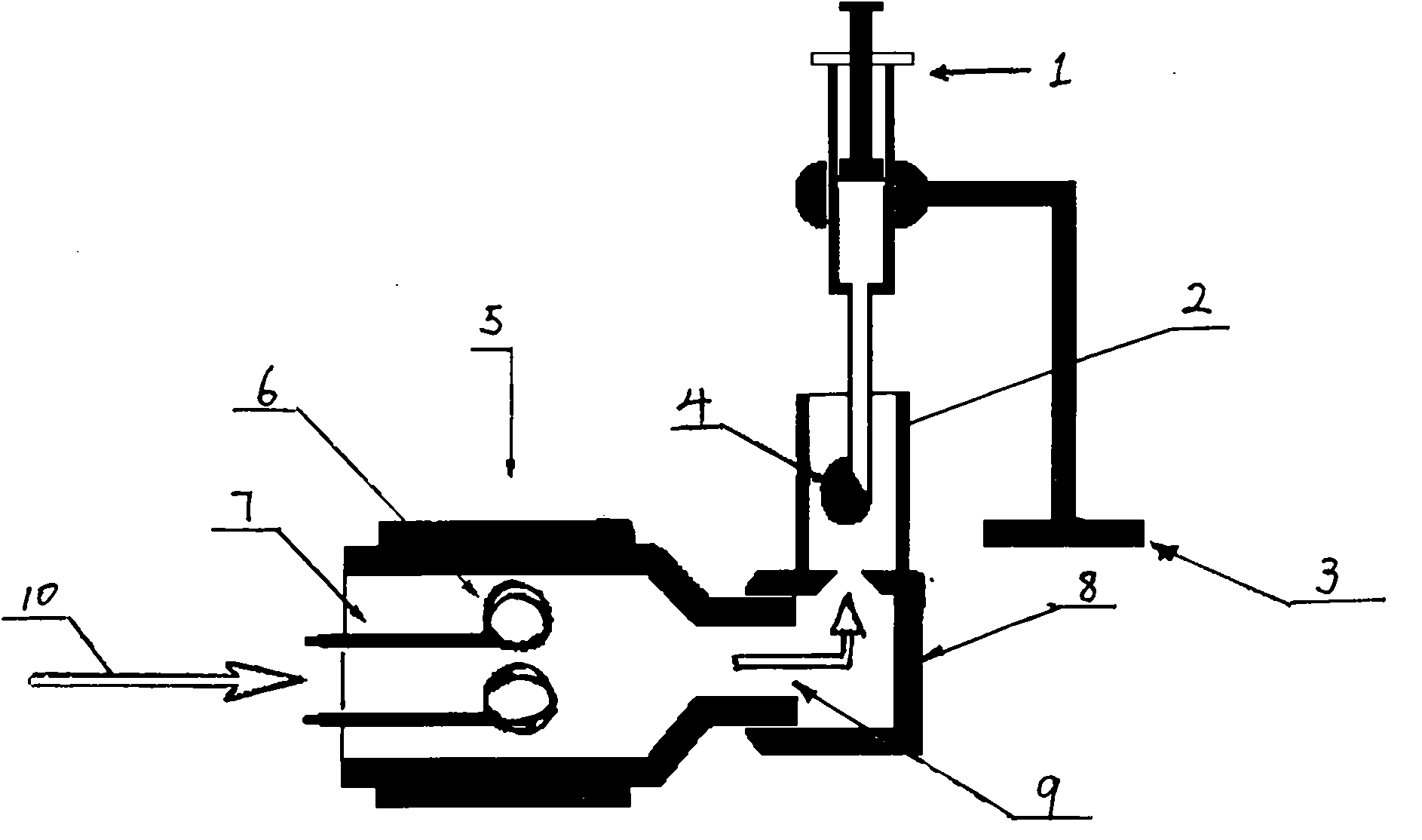

[0046] 2. The obtained thermal analysis data are as follows: figure 2 , combined with the thermogravimetric analysis data, the whole pyrolysis process is divided into 16 continuous temperature segments according to the temperature difference, using such as figure 1 Th...

Embodiment 2

[0050] Example 2: Using thermogravimetry-flowing carrier gas-single droplet microextraction device combined with gas chromatography-mass spectrometry to analyze the pyrolysis behavior of caffeic acid

[0051] 1. Accurately weigh 10.0±0.05mg of caffeic acid sample into a thermogravimetric platinum crucible. The analysis conditions are: the heating program is (keep for 10 minutes). The carrier gas is high-purity nitrogen with a flow rate of 400 mL / min.

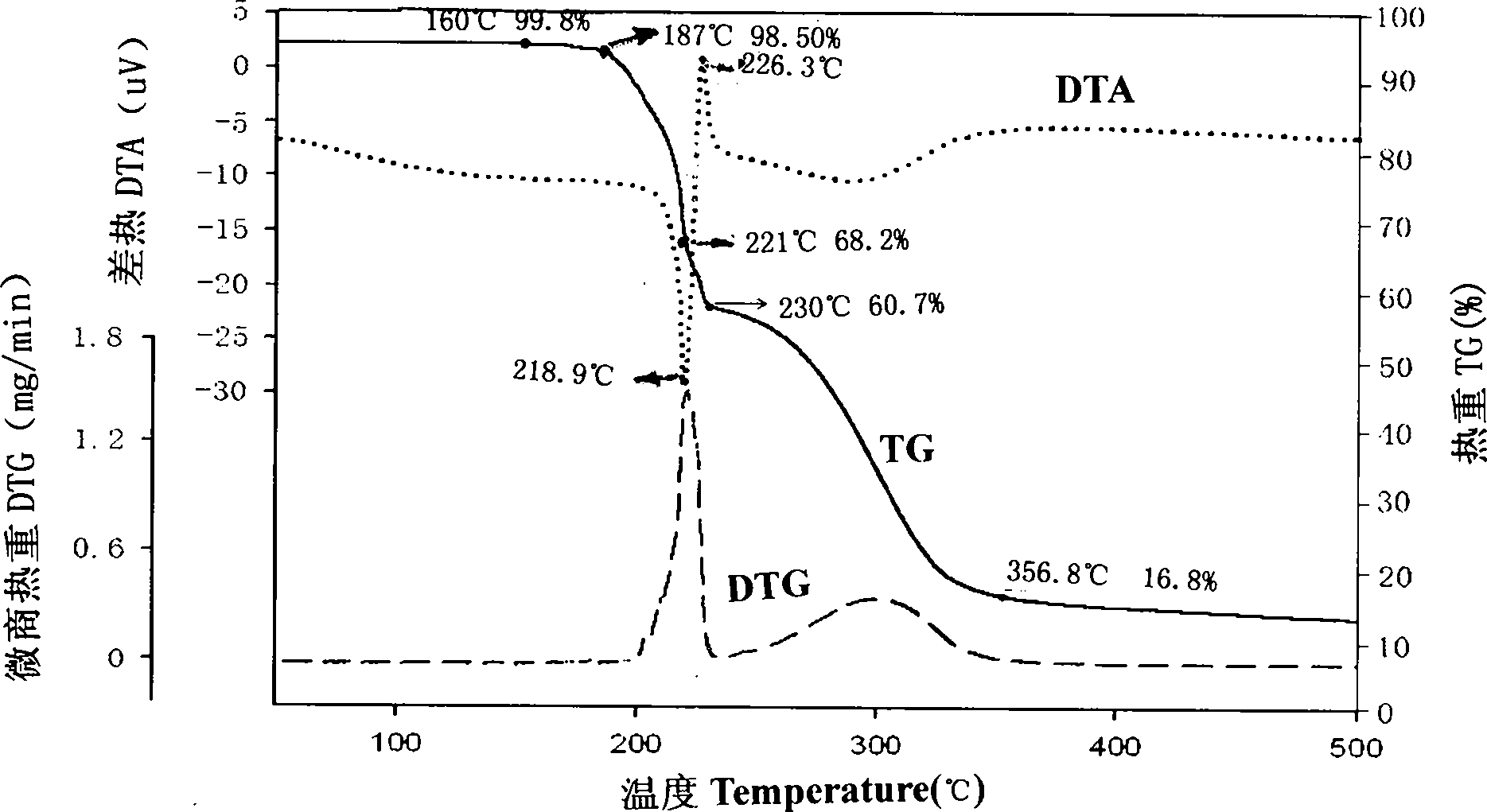

[0052] 2. The obtained thermal analysis data are as follows: Figure 5 , caffeic acid begins to lose mass at 160°C and ends at 360°C. The temperature range from 160°C to 360°C is evenly divided into 10 continuous temperature segments, and 10 extraction samples are obtained. , combined with thermogravimetric analysis data, using such as figure 1 The shown thermal analyzer and flowing carrier gas-single droplet micro-extraction device extract caffeic acid release products step by step.

[0053] 3. Select ethanol as the extra...

Embodiment 3

[0055] Example 3: Analysis of formaldehyde produced by glucose pyrolysis using thermogravimetry-flowing carrier gas-single droplet microextraction combined device

[0056] 1. Accurately weigh 10.0±0.05mg of glucose sample into a thermogravimetric platinum crucible. The analysis conditions are: (keep for 10 minutes). The carrier gas is air with a flow rate of 200mL / min.

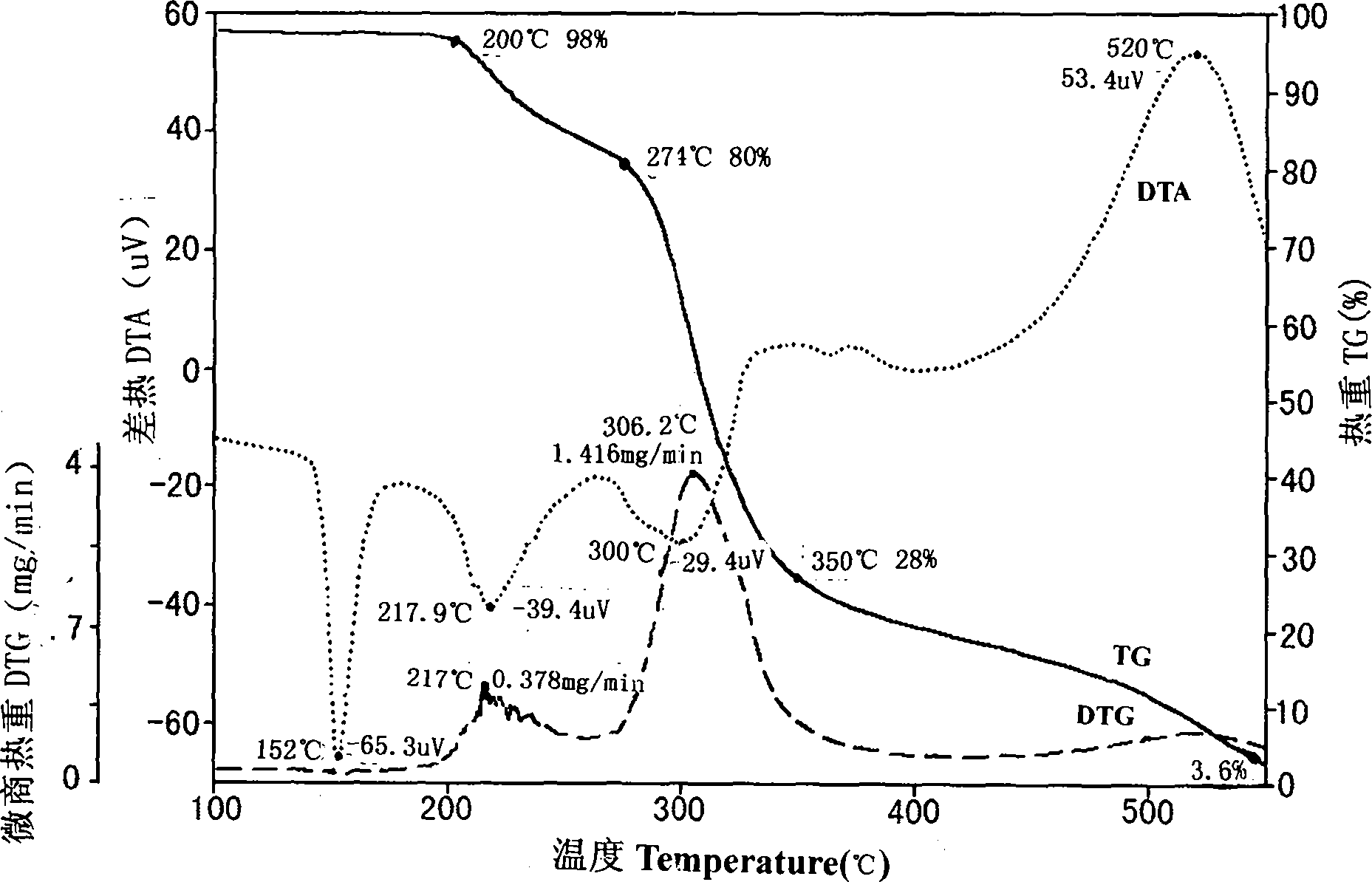

[0057] 2. The obtained thermal analysis data are as follows: Figure 7 , combined with thermogravimetric analysis data, the entire glucose pyrolysis process was performed from 200 °C to 500 °C for single droplet microextraction.

[0058] 3. Select the reaction solvent with formaldehyde characteristics: 2,4-dinitrophenylhydrazine derivatization reagent is used as the extraction solvent, and the droplet volume is kept at about 10 μL. The result of 4min extraction and sampling under the condition of thermogravimetric without adding sample was used as the blank control sample.

[0059] 4. The obtained extr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com