Method for preventing corrosion of tungsten plug

A manufacturing method and technology of metal wires, applied in the direction of electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve problems such as tungsten plug corrosion, and achieve the effect of short time and simple process method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

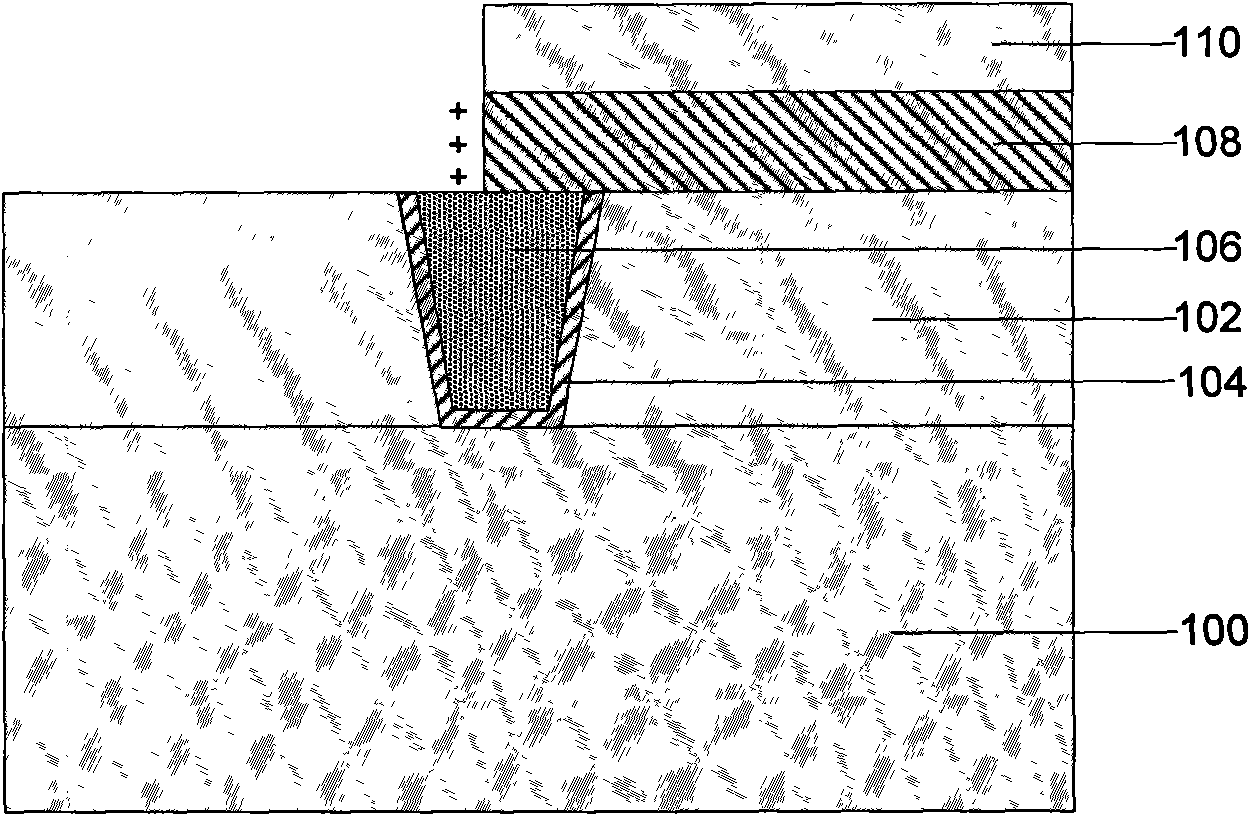

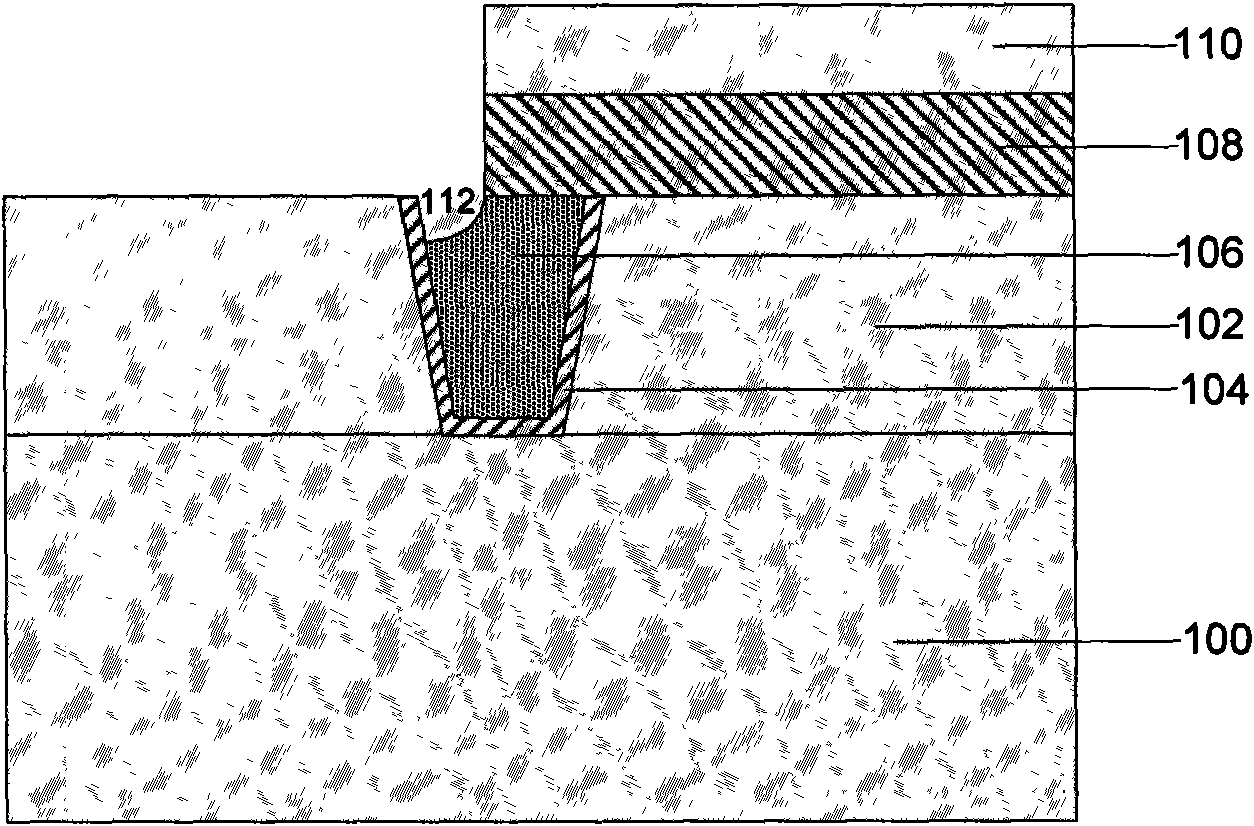

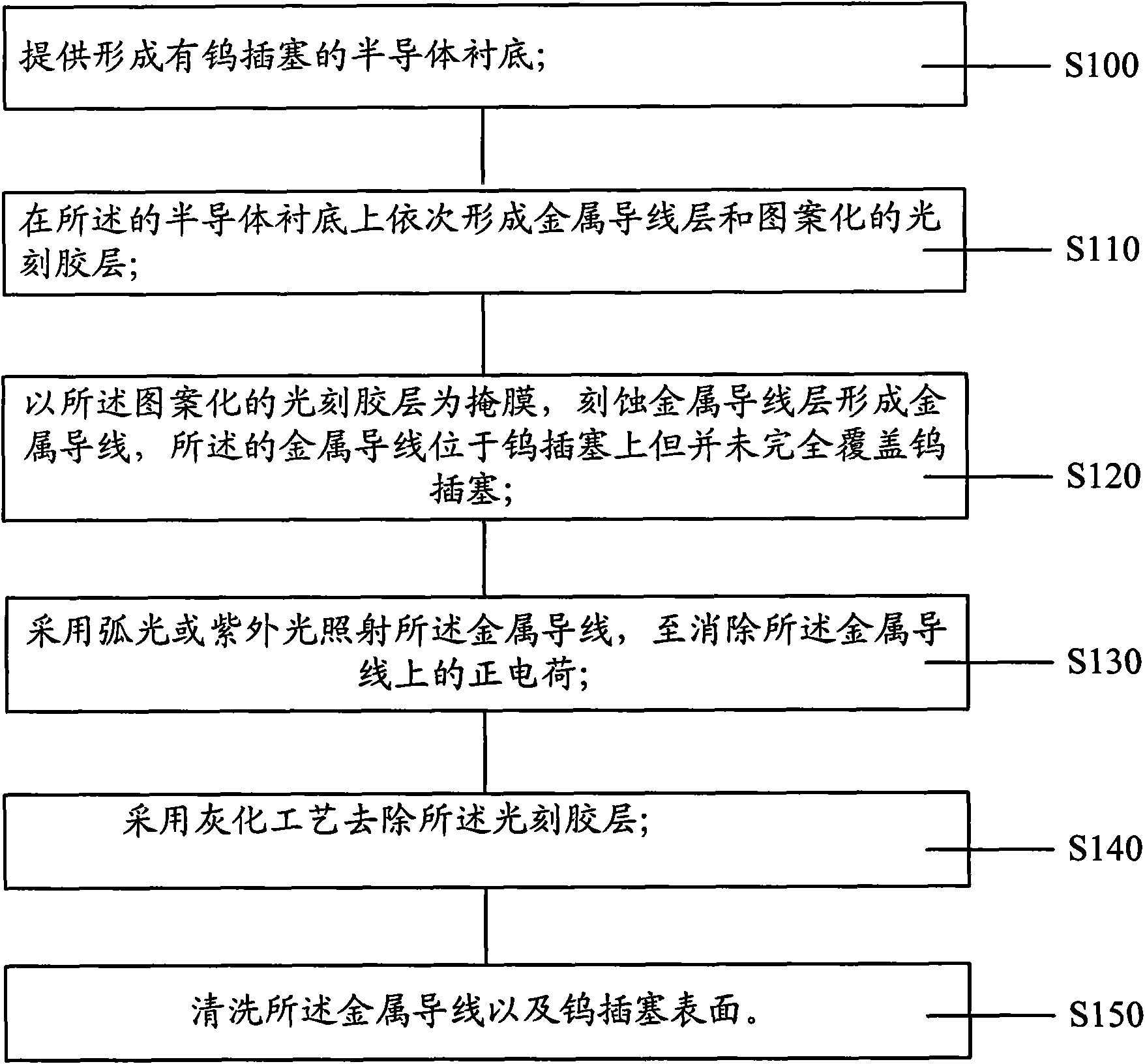

[0022] Reference attached figure 2 As shown, the manufacturing method of a semiconductor device provided by this embodiment includes: step S100, providing a semiconductor substrate with tungsten plugs formed thereon; step S110, sequentially forming a metal wire layer on the semiconductor substrate and a patterned photoresist layer; step S120, using the patterned photoresist layer as a mask, etching the metal wire layer to form a metal wire, and the metal wire is located on the tungsten plug but not completely covered Tungsten plug; Step S130, using arc light or ultraviolet light to irradiate the metal wire to eliminate the positive charge on the metal wire; Step S140, using an ashing process to remove the photoresist layer; Step S150, cleaning the metal leads and tungsten plug surfaces.

[0023] Reference attached Figure 3a As shown, a semiconductor substrate 200 is provided, and a tungsten plug 201 is formed in the semiconductor substrate. The structure of the semiconduct...

Embodiment 2

[0035] This embodiment provides a method for preventing corrosion of tungsten plugs, comprising: providing a semiconductor substrate with tungsten plugs formed, the tungsten plugs and the tungsten plugs formed on the tungsten plugs but not completely covering the tungsten plugs The metal wires are interconnected; the metal wires are irradiated with arc light or ultraviolet light to eliminate the positive charges on the metal wires.

[0036] The structure of the semiconductor substrate and the manufacturing method of the metal wire layer refer to Embodiment 1, which will not be repeated here.

[0037] Using the method for preventing corrosion of tungsten plugs, due to the use of arc light or ultraviolet light irradiation, the positive charges on the metal wires are removed. Therefore, in the subsequent cleaning process, corrosion on the metal wires and the tungsten plugs is avoided. The potential difference avoids the occurrence of electrochemical reaction and prevents the tung...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com