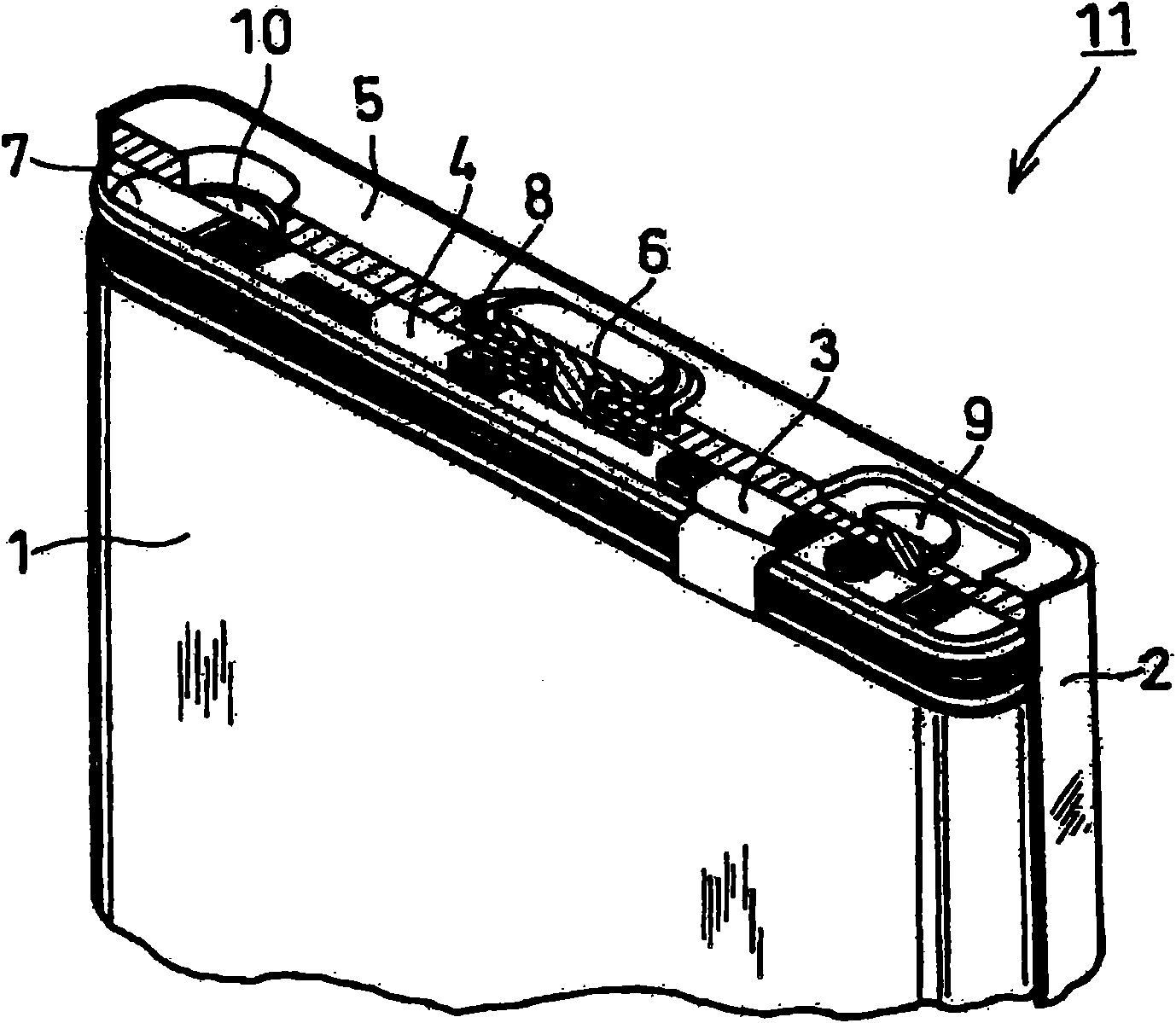

Method for producing positive electrode for lithium ion battery, positive electrode for lithium ion battery, and lithium ion battery using the positive electrode

A lithium-ion battery and a manufacturing method technology, applied in battery electrodes, secondary batteries, circuits, etc., can solve problems such as insufficient removal, and achieve the effect of excellent storage characteristics and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] (1) Preparation and cleaning of the positive electrode

[0083] 1kg of LiNi 0.80 co 0.15 al 0.05 o 2 powder, 0.5kg of NMP solution of polyvinylidene fluoride (#1320 produced by Kureha Chemical Co., Ltd., solid content concentration of 12% by mass), 40g of acetylene black, and an appropriate amount of NMP are thrown into a double-arm mixer together, and mixed at 30 The mixture was stirred for 30 minutes at °C to prepare a paste for forming a positive electrode active material layer. The obtained paste was applied to both surfaces of a 20 μm thick aluminum foil serving as a positive electrode current collector, and dried at 120° C. for 15 minutes to form a positive electrode active material layer. Then, the total thickness of the positive electrode current collector and the positive electrode active material layer was adjusted to 160 μm by pressing with a roll press, thereby obtaining a positive electrode. The obtained positive electrode was cut into a size that can ...

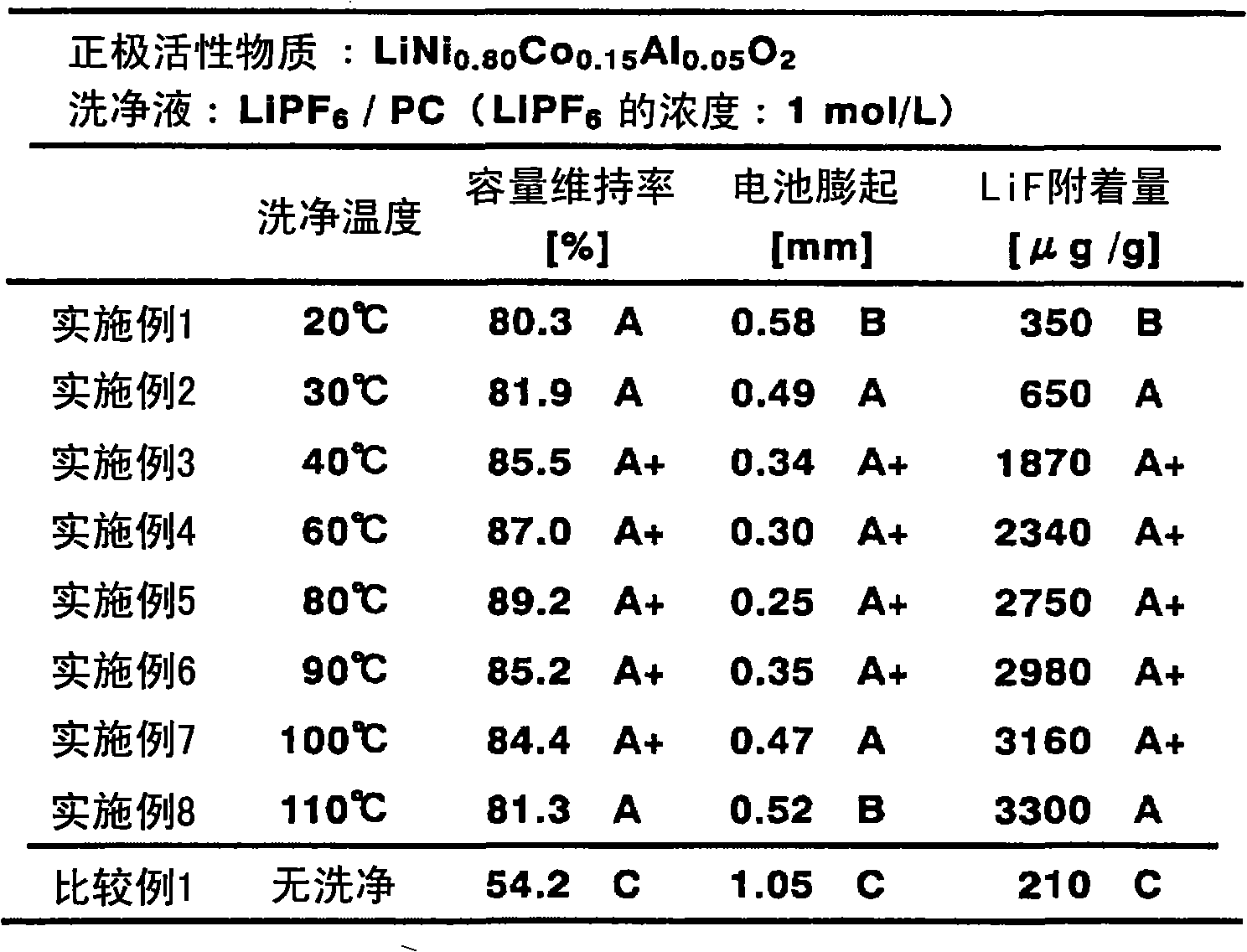

Embodiment 2~8

[0102] Lithium ion batteries were produced in the same manner as in Example 1 except that the temperature during the cleaning treatment of the positive electrode was set to the value shown in Table 1 below, and their physical properties were evaluated.

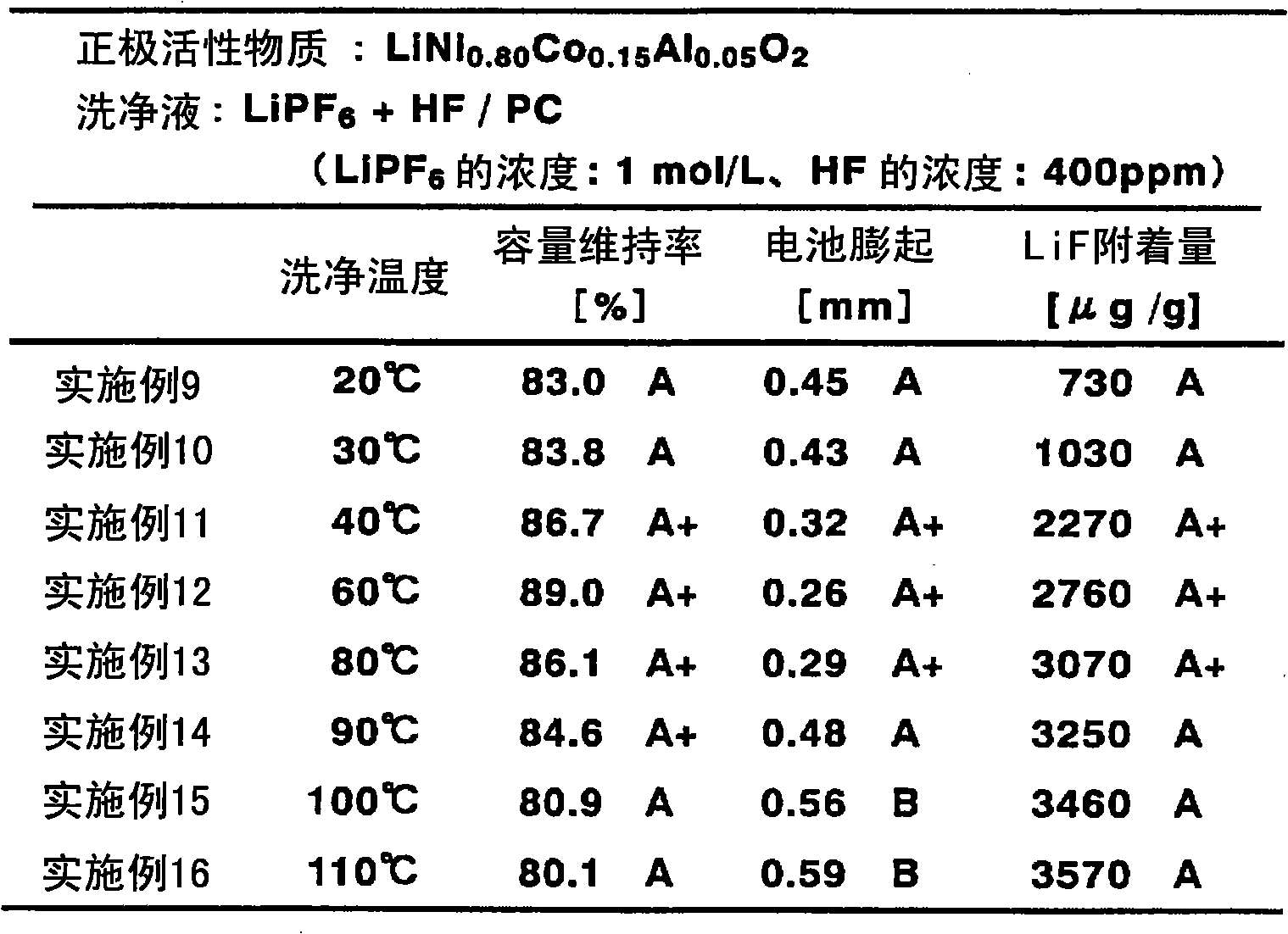

Embodiment 9~16

[0106] Dissolve 15.2g LiPF relative to 100mL of PC 6 , and then add hydrogen fluoride (HF) to prepare a positive electrode cleaning solution. The resulting cleaning solution (LiPF 6 +LiPF in HF / PC) 6 The concentration of HF is 1.0mol / L, and the concentration of HF is 400ppm. In addition to replacing LiPF 6 / PC and the above-mentioned positive electrode cleaning solution (LiPF 6 +HF / PC), lithium ion batteries were produced in the same manner as in Examples 1 to 8. In addition, the physical properties of the obtained lithium ion battery were evaluated in the same manner as in Example 1. The above results are shown in Table 2 below.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com