Monox hollow sphere material with multi-stage pore structure and preparation method of monox hollow sphere material

A technology of mesoporous structure and silicon oxide, applied in the direction of silicon oxide, silicon dioxide, crystalline aluminosilicate zeolite, etc., to achieve the effects of reduced synthesis cost, high specific surface area, and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

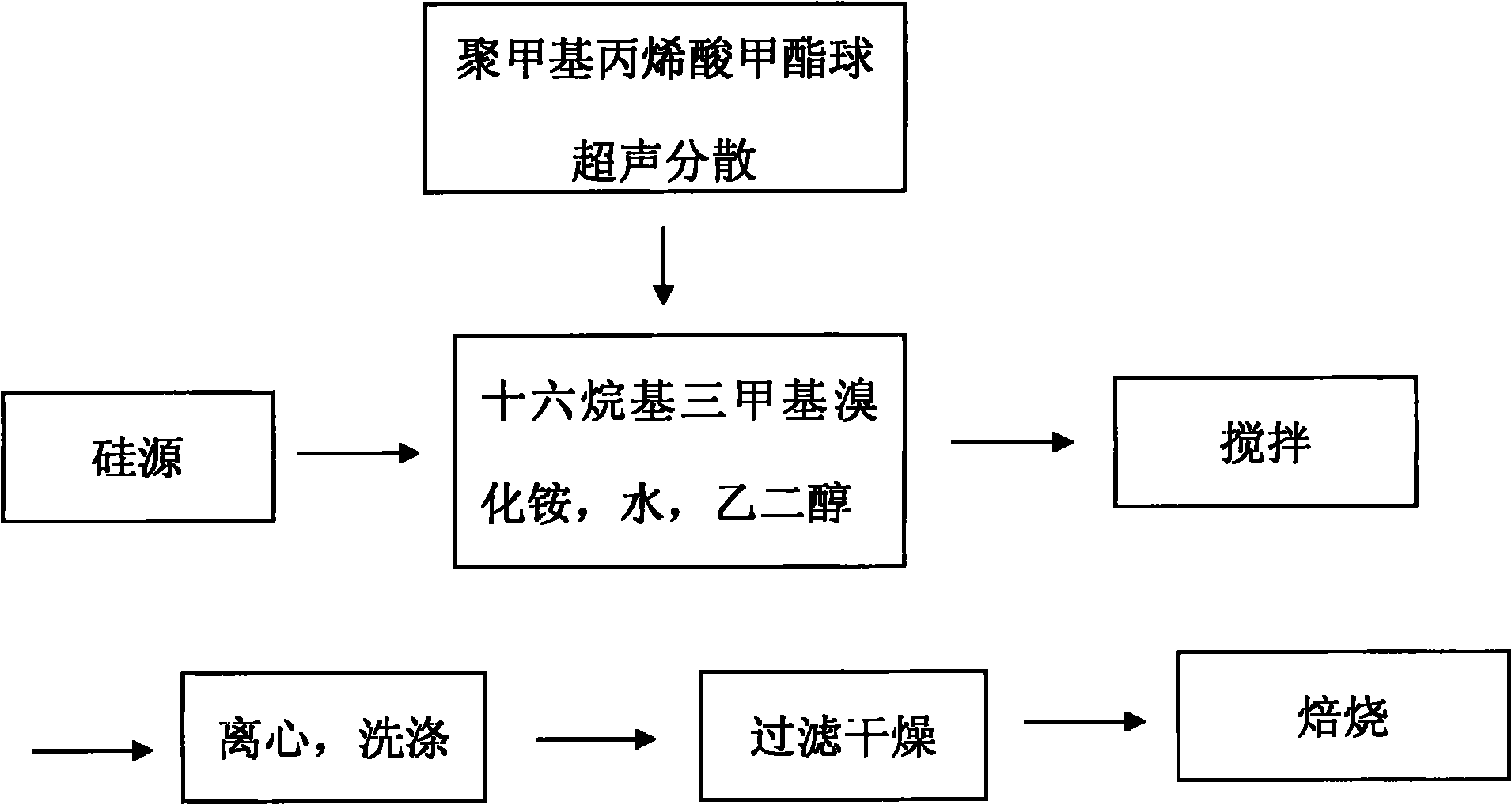

Method used

Image

Examples

Embodiment 1

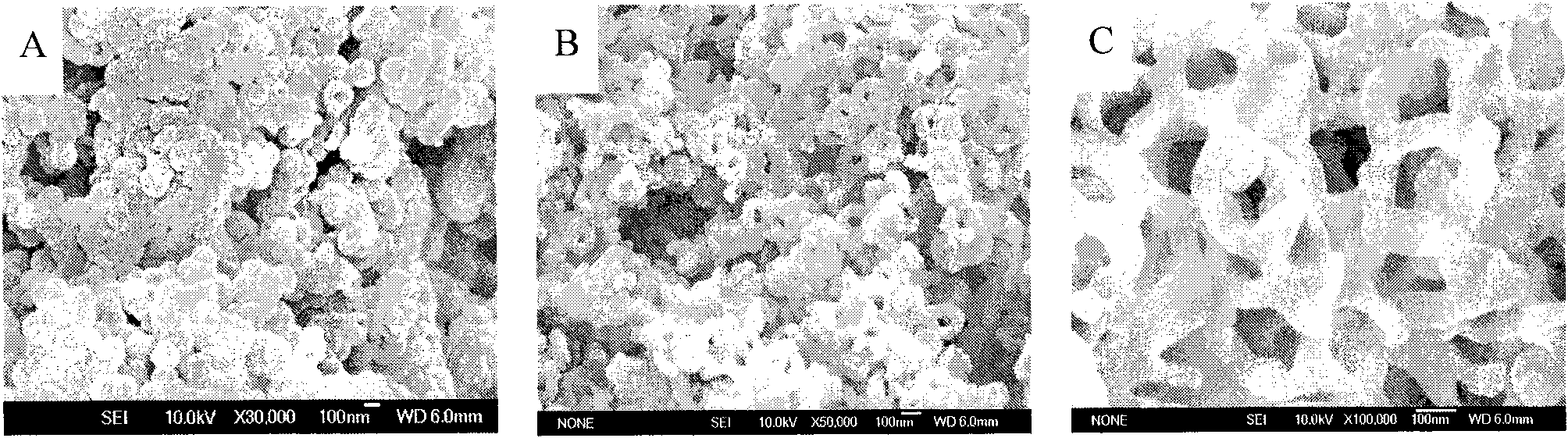

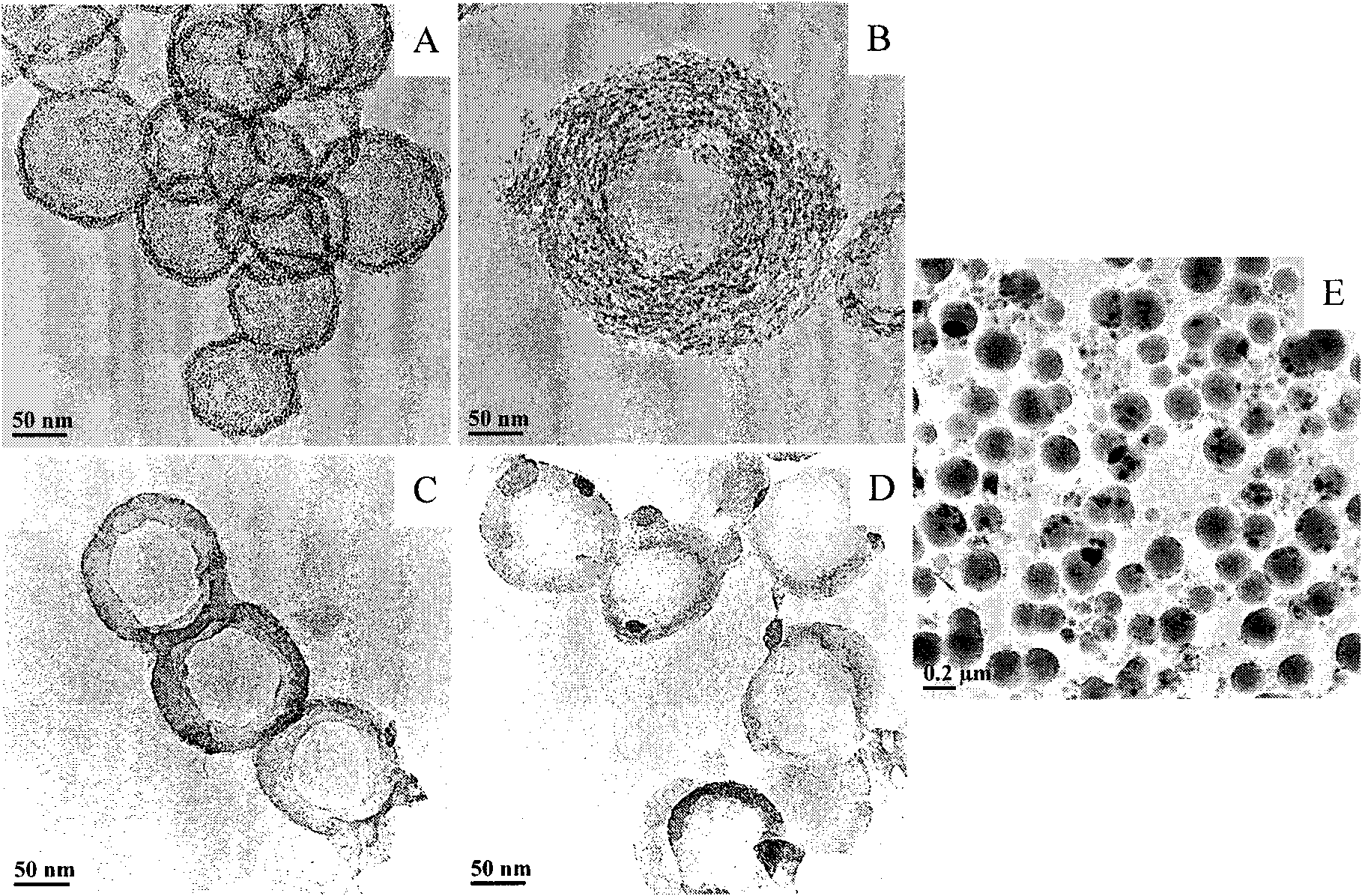

[0026] Synthesis of hollow silicon oxide spheres with multi-level mesoporous structure: First, ultrasonically disperse PMMA powder in water, then add tetraethyl orthosilicate and monoamine dropwise to CTAB, ethylene glycol, and ammonia solution, and stir for 1 hour , was added to the PMMA emulsion and stirred for 2 hours. The molar ratio of reactants is 22TEOS / 3.5APTES / 900EG / 12800H 2 O / 385NH 3 / 9CTAB / 0.04PMMA. The above solution was centrifugally washed and dried, and calcined at 550° C. for 6 hours to obtain mesoporous silica hollow spheres with a hierarchical pore structure. Typical XRD spectra, SEM, TEM, and nitrogen adsorption curves prove that the product is an ordered mesoporous channel, a hierarchical porous structure with a high specific surface area, and a uniform size silica hollow sphere. The mesopore diameter is 2.34 and 18.8nm, and the specific surface area 812m 2 / g, the total pore volume is 0.76cm 3 / g, the diameter of the hollow sphere is 50-100nm.

Embodiment 2

[0028] According to the experimental method of Example 1, the content of each component is changed to 6TEOS / 1.2APTES / 900EG / 12800H 2 O / 385NH 3 / 3CTAB / 0.04PMMA, the material structure changes as figure 2 B, 3B, is the hollow ring of mesoporous silica.

Embodiment 3

[0030] According to the experimental method of Example 1, the content of each component is changed to 6TEOS / 900EG / 12800H 2 O / 385NH 3 / 3CTAB / 0.04PMMA, the material structure changes as image 3 C, is a hollow ring of silicon oxide without mesoporous channels.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com