Device and method for producing methyl isobutyl ketone (MIBK) by using acetone (AC)

A kind of acetone and product technology, applied in the field of methyl isobutyl ketone production equipment, can solve the problems that IPA cannot be separated, the separation system cannot operate smoothly, and a large amount of energy is wasted, so as to achieve stable operation, improve competitiveness, The effect of increasing the yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

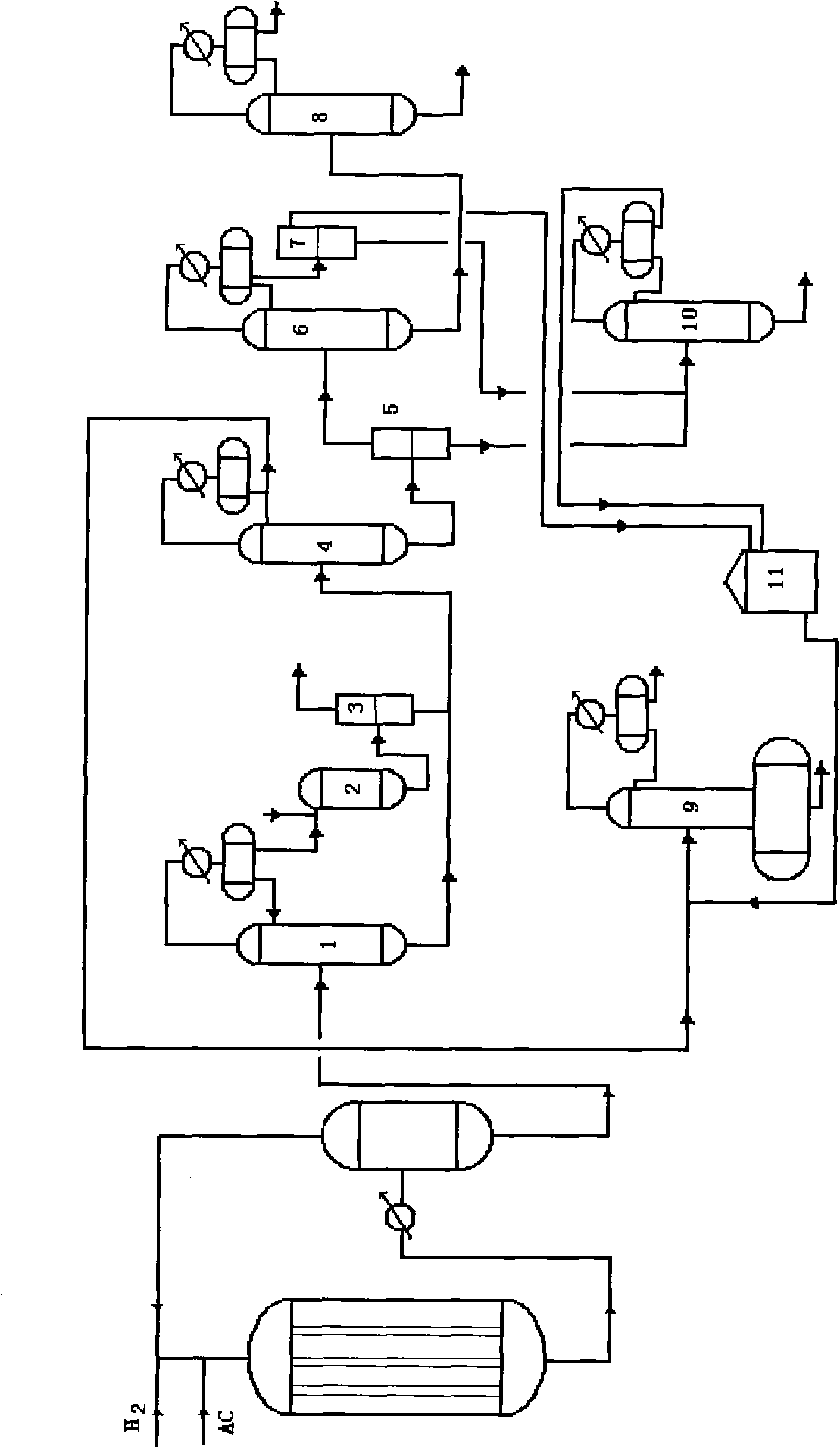

[0072] The process adopted by the embodiment is figure 1 Introduced process.

[0073] 1, the situation of the raw material used in embodiment

[0074] Table 1 is composed of raw materials sent from the reaction system to the separation system.

[0075] Table 1 Raw material composition

[0076] name

Composition, wt%

h 2 o

4.71

2-MPA

0.54

AC

69.51

IPA

0.66

MIBK

24.02

DIBK

1.10

TMB

0.50

total

100%

[0077] 2. Device introduction

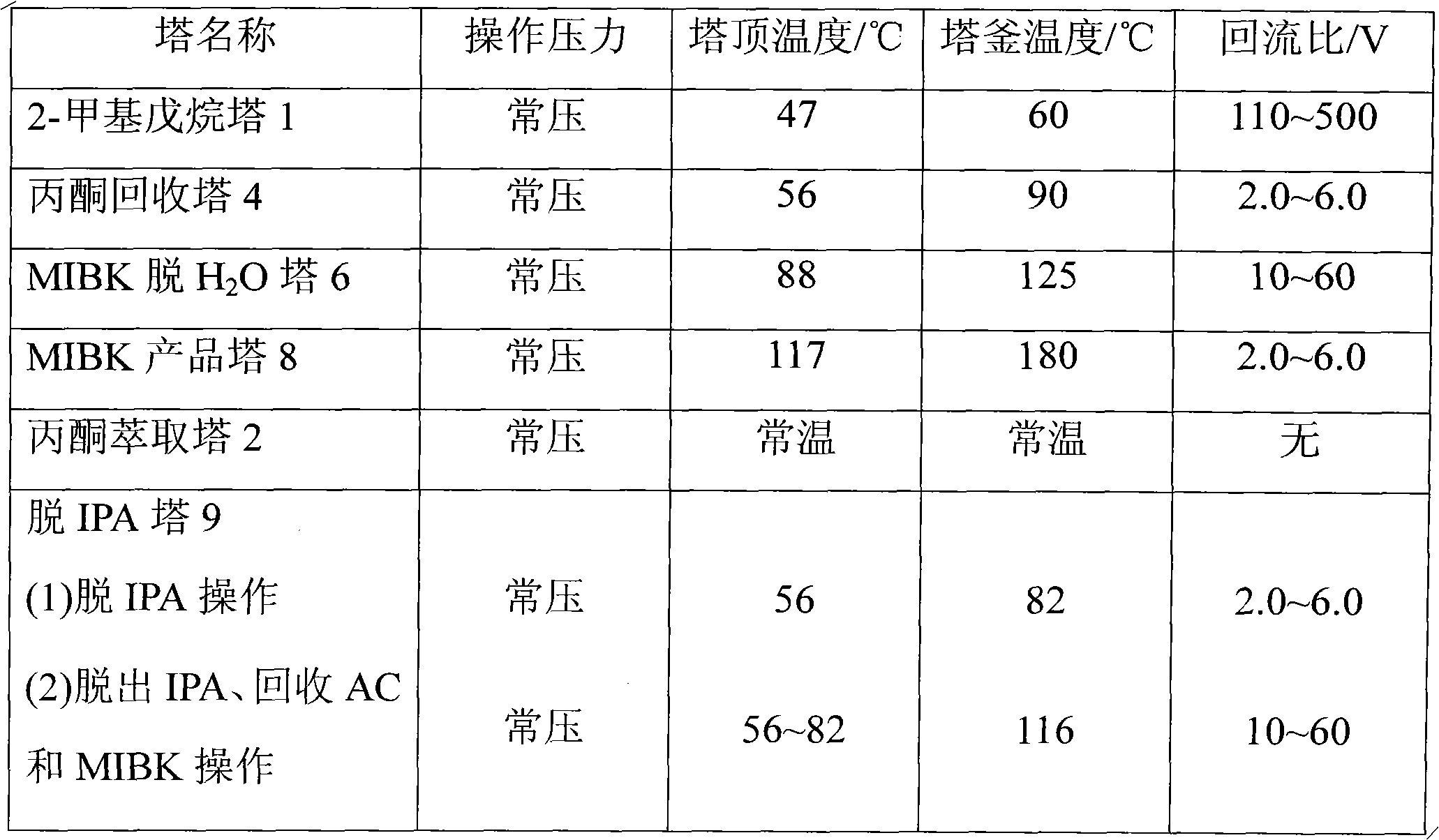

[0078] The material that comes out from the hydrogen separator first enters the 2-methylpentane tower 1, and the 2-MPA tower includes the feed line from the hydrogen separator to the 2-MPA tower 1, and the overhead product is removed from the device, and the overhead product passes through After condensation, a part of condensed tower top product is fed to acetone extraction tower 2 by pipeline; Acetone extraction tower 2 comprises...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com