Integral compressed air heat recovery device

A compressed air and heat energy recovery technology, applied in liquid variable capacity machinery, variable capacity pump components, machines/engines, etc., can solve problems such as increased operating costs, water system pollution, and inability to recover waste heat, and is conducive to smooth operation. , the effect of temperature stabilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

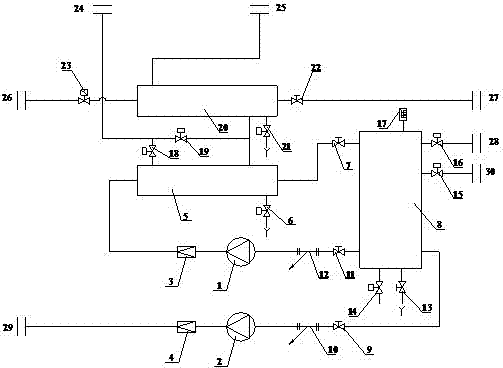

[0021] Embodiment: integrated compressed air heat energy recovery device, including circulating water pump 1, delivery water pump 2, check valve 3, 4, heat exchanger 5, automatic drainer 6, 21, stop valve 7, 9, 11, 22, circulation Water tank 8, water filter 10, 12, manual drain valve 13, electric drain valve 14, replenishment solenoid valve 15, 16, exhaust valve 17, pneumatic valve 18, 19, cooler 20, electric regulating valve 23, air inlet pipe , Air outlet pipes, cooling water inlet pipes, cooling water outlet pipes, hot water supply pipes, tap water pipes 28, high water tank backwater pipes 30.

[0022] High-temperature air treatment system: the air inlet pipe is connected to the inlet of the pneumatic valve 18, 19, the outlet of the pneumatic valve 18 is connected to the air inlet 24 of the heat exchanger 5, the air outlet of the heat exchanger 5 is connected to the air inlet of the cooler 20, and The air outlet 25 of the cooler 20 is connected with the air outlet pipe, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com