Fully-biodegradable foaming material and application thereof

A foaming material, biodegradable technology, applied in applications, home appliances, other seating furniture, etc., can solve the problems of difficult foaming materials, difficult to degrade, toughness and elasticity requirements, etc., to achieve excellent compression resistance and durability Abrasion resistance, improved impact toughness, and excellent antibacterial properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

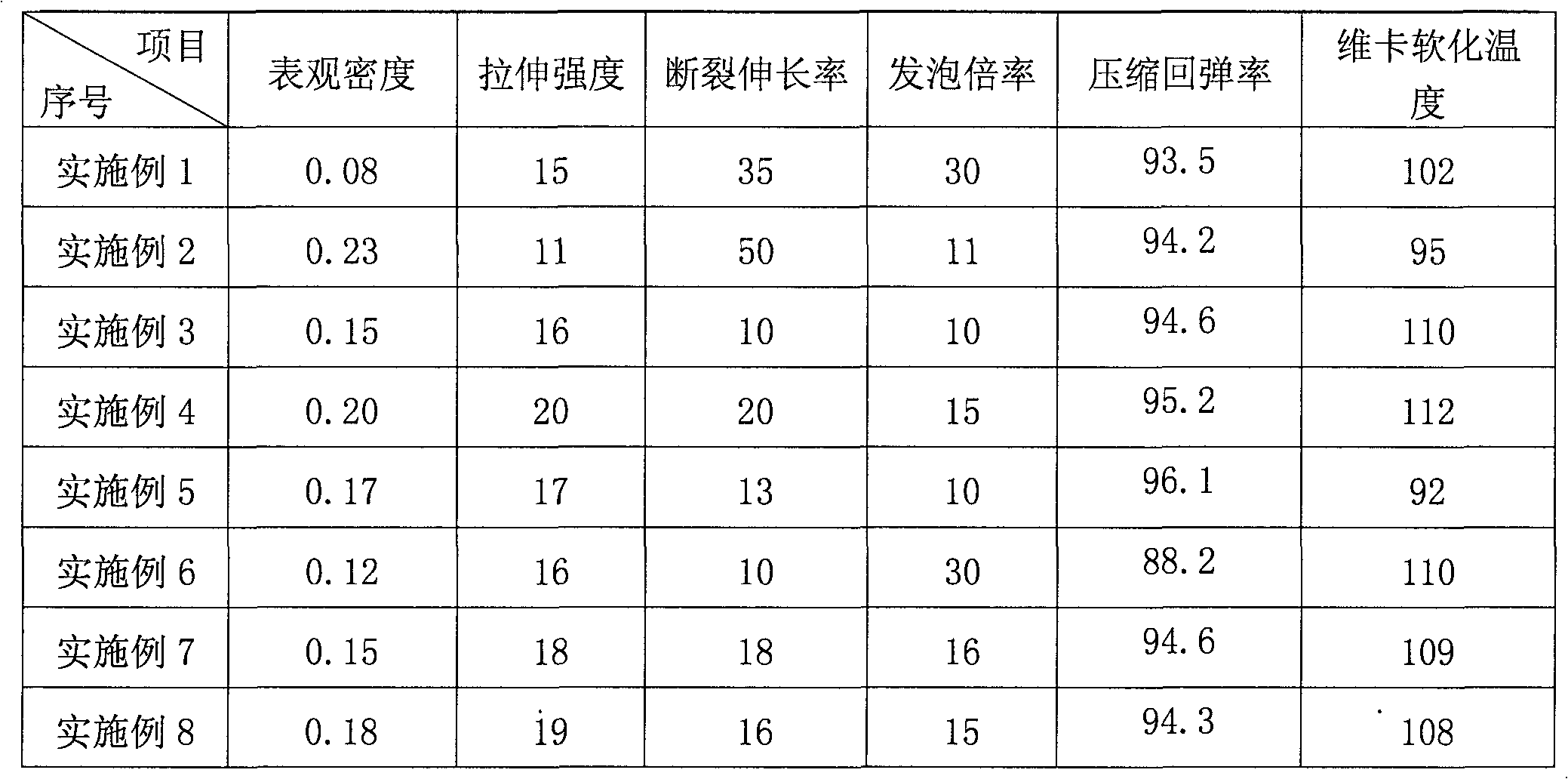

Examples

Embodiment 1

[0020] 100 parts of poly 3-hydroxybutyrate-4-hydroxybutyrate (P3HB4HB, 4-hydroxybutyric acid molar content is 10%), 35 parts of plasticizer ethylene glycol, foaming agent azodicarbonamide 6 Add one portion into a high-speed mixer and stir at high speed for 5 minutes, then put the mixed material into a twin-screw extruder for melting and foaming, and the blending temperature is 120°C.

Embodiment 2

[0022] 100 parts of poly 3-hydroxybutyrate-3-hydroxyhexanoate (PHBHHx, 3-hydroxyhexanoic acid molar content is 12%), 15 parts of plasticizer propylene glycol, foaming agent diisopropyl azodicarbonate 1.5 parts were added into a high-speed mixer and mixed at a high speed for 5 minutes, and the others were the same as in Example 1 to obtain a foamed material.

Embodiment 3

[0024] Add 100 parts of polyhydroxybutyrate valeric acid copolyester (PHBV, 3-hydroxyvaleric acid molar content is 15%), 5 parts of glycerin, 15 parts of epoxy soybean oil, and 3.5 parts of sodium bicarbonate into a high-speed mixer and mix at high speed 5 minutes, other with embodiment 1, obtain foaming material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com