Inorganic modified coal pitch and preparation method thereof

A technology of inorganic modification and coal tar pitch, applied in building components, building insulation materials, construction and other directions, can solve the problem of not fully satisfying the production of high-quality carbon electrode materials for aluminum, and achieve low cost, easy operation, and increased resin content. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

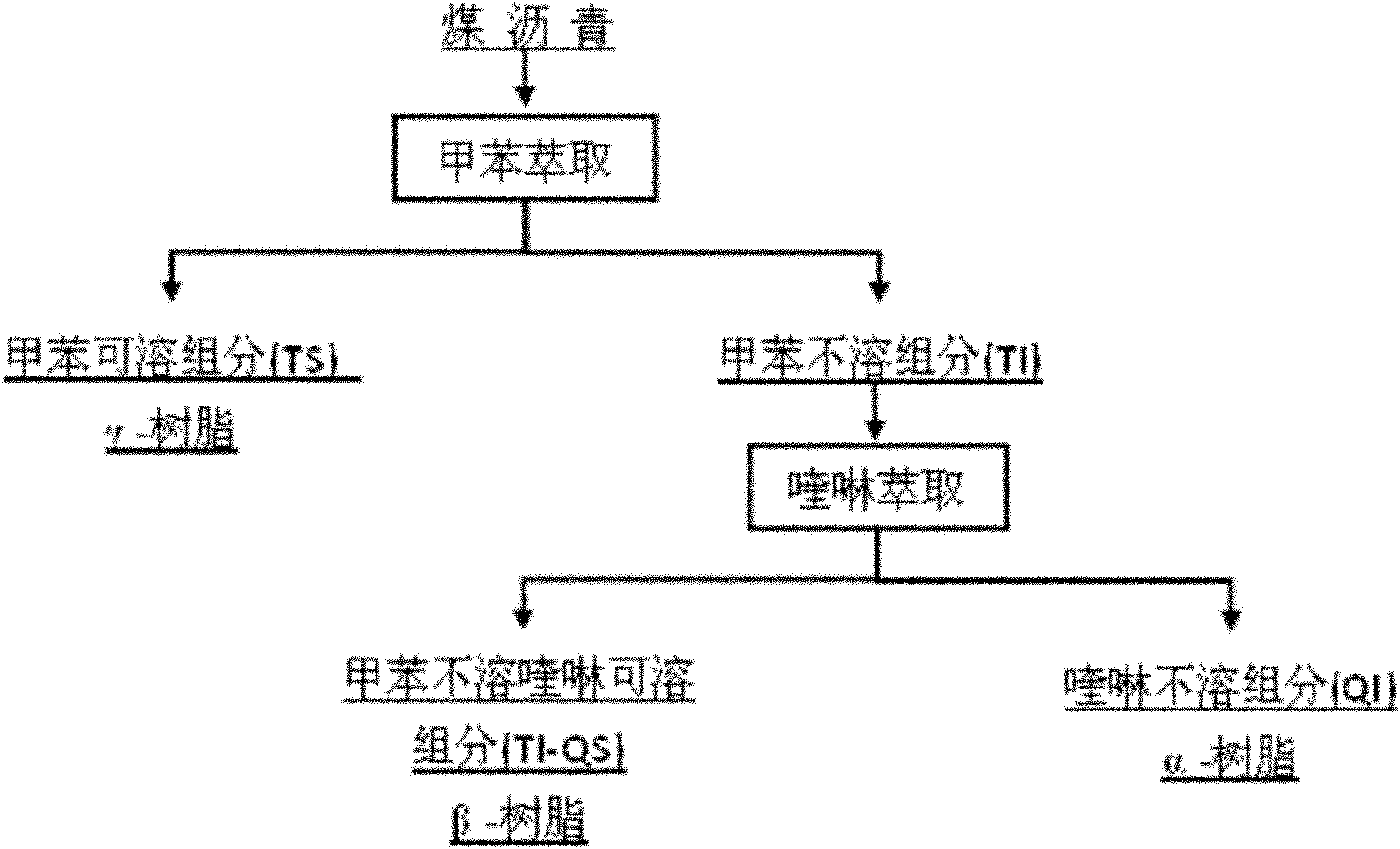

[0031] Raw material formula: coal tar pitch (particle size: ≤150μm): 90%, AlF 3 Powder (particle size: 10-150 μm): 10%.

[0032] Weighing according to the above formula, coal tar pitch and AlF 3 Mix the powder evenly, put the mixture into the reactor, heat up to 150°C at a rate of 5°C / min, control the pressure inside the reactor: 5.0MPa, stir speed: 150r / min, and modify for 6.0h.

[0033] The coking value of the prepared modified coal tar pitch is 57%, the content of TI is 28%, the content of QI is 8%, and the content of β resin is 20%. The modified coal tar pitch was used to prepare carbon anode for aluminum electrolysis. Compared with the original coal pitch based carbon anode, the volume density of the modified coal tar pitch based carbon anode increased by 3.5%, and the compressive strength increased by 6.8%. , the flexural strength increased by 4.6%, the oxidation resistance of the prepared carbon anode was significantly improved, and the carbon slag in the electrolyte ...

Embodiment 2

[0035] Raw material formula: coal tar pitch (particle size: ≤150μm): 90%, TiB 2 Powder (particle size: 10-150 μm): 10%.

[0036] Weighing according to the above formula, the coal tar pitch and TiB 2 Mix the powder evenly, put the mixture into the reactor, heat up to 200°C at a rate of 5°C / min, control the pressure inside the reactor: 1.0MPa, stir speed: 150r / min, and modify for 6.0h.

[0037] The coking value of the prepared modified coal tar pitch is 58%, the content of TI is 30%, the content of QI is 8.3%, and the content of β resin is 21.7%. The modified coal tar pitch was used to prepare the carbon cathode for aluminum electrolysis. Compared with the original coal pitch based carbon cathode, the volume density of the modified coal tar pitch based carbon cathode increased by 5.5%, and the compressive strength increased by 8.2%. , the corrosion resistance and electrolytic expansion resistance of the prepared carbon cathode are significantly improved, and the electrolytic e...

Embodiment 3

[0039] Raw material formula: coal tar pitch (particle size: ≤150μm): 95%, Al 2 o 3 Sol (50-100nm): 5%.

[0040] Weighing according to the above formula, coal tar pitch and Al 2 o 3 The sol was mixed evenly, and the mixture was put into the reactor, and the temperature was raised to 300°C at a rate of 5°C / min. The pressure inside the reactor was controlled at 0.1MPa, the stirring speed was 150r / min, and the modification was performed for 3.0h.

[0041] The coking value of the prepared modified coal tar pitch is 56%, the content of TI is 29%, the content of QI is 8.5%, and the content of β resin is 20.5%. Using this modified coal tar pitch for aluminum electrolysis with TiB 2 / C composite cathode, with pristine coal tar pitch-based TiB 2 / C composite cathode, the bulk density of the modified coal tar pitch-based composite cathode increased by 4.8%, and the compressive strength increased by 7.6%, and the prepared TiB 2 / C composite cathode has significantly improved corrosion...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com