Lactobacillus casei and application of lactobacillus casei in ferment production of L-lactic acid

A technology of Lactobacillus casei and lactic acid, applied in the direction of fermentation, microbial-based methods, bacteria, etc., can solve the problems of unsuitable lactic acid industrial production, increased fermentation and extraction costs, and complicated extraction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

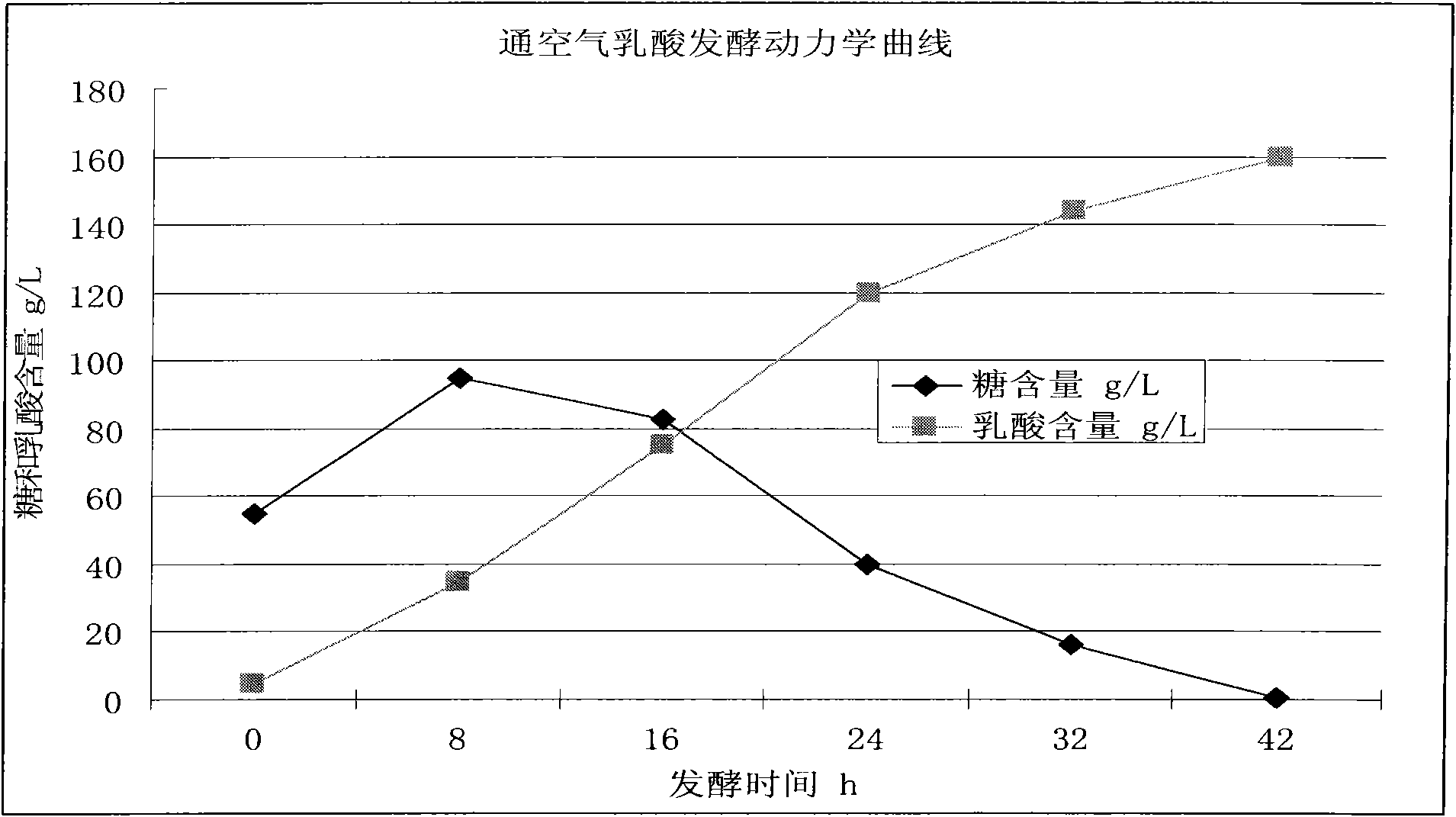

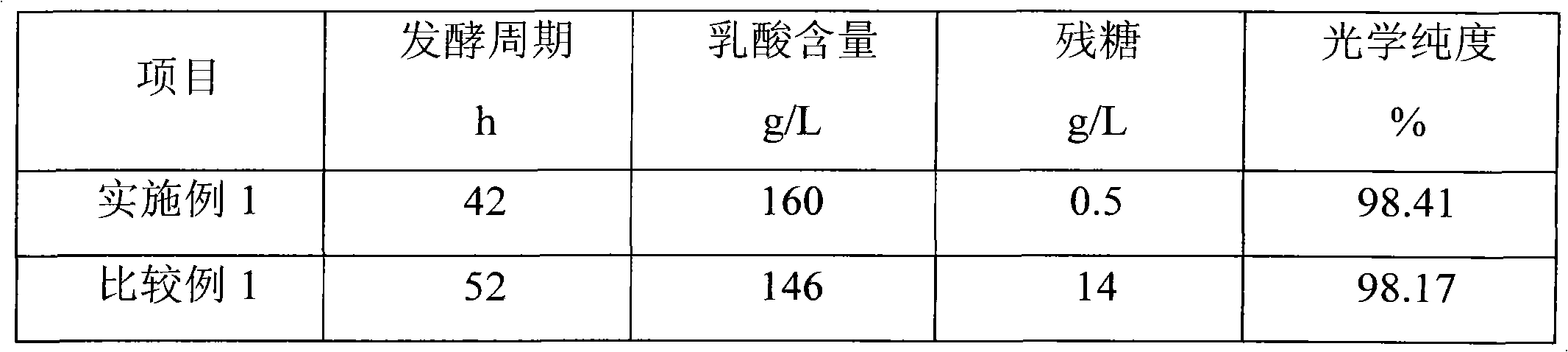

[0042] The present embodiment is the fermentation test under the air situation:

[0043] Add 2.4kg of corn flour to tap water to make a 17.1% solution, add 1kg of light calcium carbonate, 2.0mL of high-temperature amylase, liquefy at 98°C for 1 hour, cool down to 42°C, add 7.2mL of starch glucoamylase, keep warm for 3 hours, and measure glucose The concentration is 55g / L.

[0044] Lactobacillus casei FY-04 was cultured to the logarithmic phase in the medium, added to the fermenter, and fermented at 42°C, 150rpm, pH 6.0, at a space velocity of 10.0h -1 Air was introduced and fermented for 42 hours, the concentration of lactic acid reached the maximum value of 160g / L, and the concentration of glucose was 0.5g / L.

Embodiment 2

[0054] Add 2.4kg of corn flour to tap water to make a 17.1% solution, add 1kg of light calcium carbonate, 2.0mL of high-temperature amylase, liquefy at 98°C for 1 hour, cool down to 42°C, add 7.2mL of starch glucoamylase, keep warm for 3 hours, and measure glucose The concentration is 55g / L.

[0055] Lactobacillus casei FY-04 was cultured to the logarithmic phase in the medium, added to the fermenter, and fermented at 42°C, 150rpm, pH 6.0, at a space velocity of 10.0h -1 Air was introduced and fermented for 42 hours, the concentration of lactic acid reached the maximum value of 160g / L, and the concentration of glucose was 0.5g / L.

Embodiment 3

[0057] Add 2.4kg of corn flour to tap water to make a 17.1% solution, add 1kg of light calcium carbonate, 2.0mL of high-temperature amylase, liquefy at 98°C for 1 hour, cool down to 42°C, add 7.2mL of starch glucoamylase, keep warm for 3 hours, and measure glucose The concentration is 55g / L.

[0058] Lactobacillus casei FY-04 was cultured to the logarithmic phase in the medium, added to the fermenter, and fermented at 42°C, 150rpm, pH 6.0, at a space velocity of 10.0h -1 Air was introduced and fermented for 42 hours, the concentration of lactic acid reached the maximum value of 160g / L, and the concentration of glucose was 0.5g / L.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com