Metal selenide thermoelectric material for intermediate temperate and preparation process thereof

A technology of metal selenide and thermoelectric materials, which is applied in the field of metal selenide thermoelectric materials and preparation technology for medium temperature, can solve the problems of low productivity, high equipment requirements, and limited production scale, and achieve the effect of low cost and simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

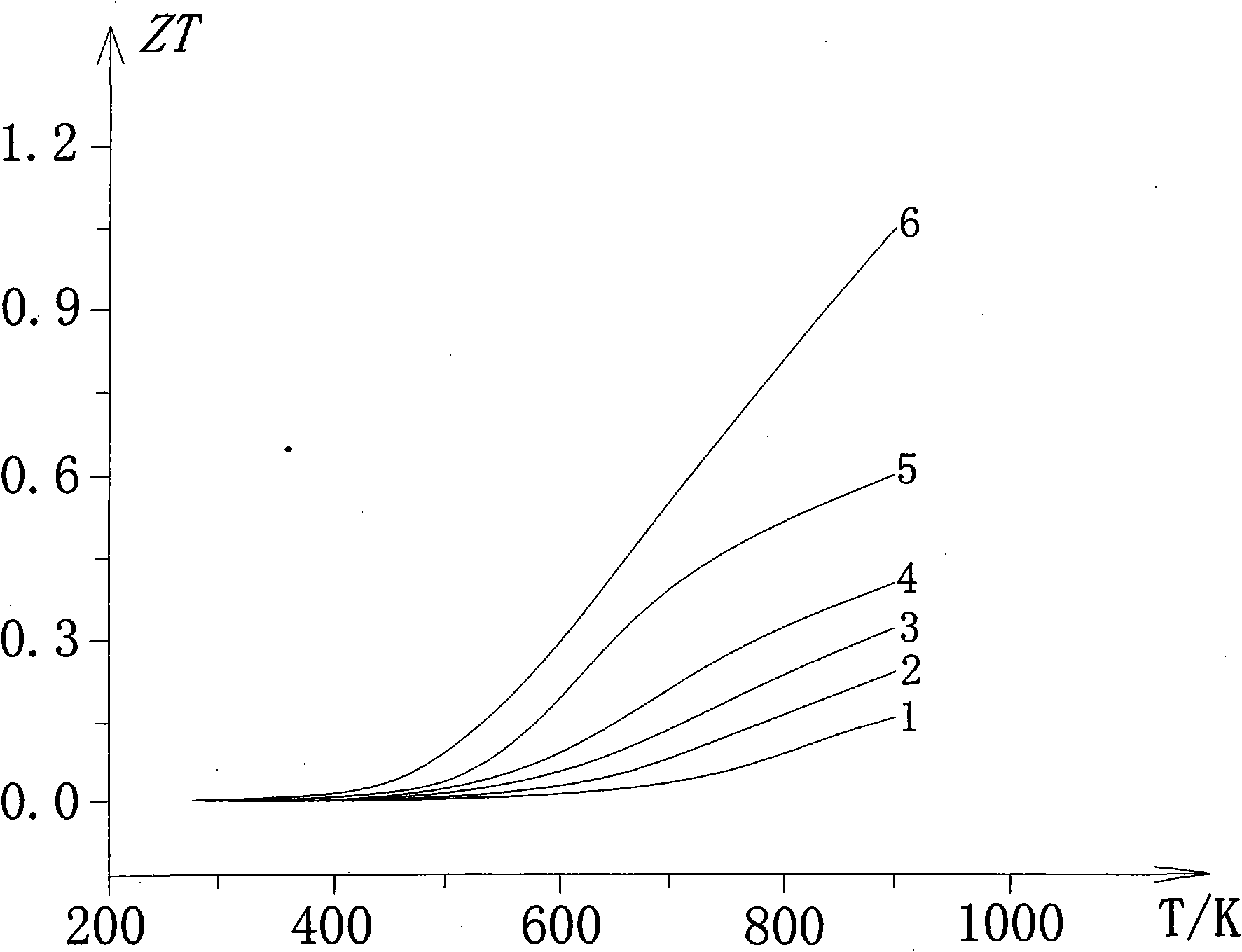

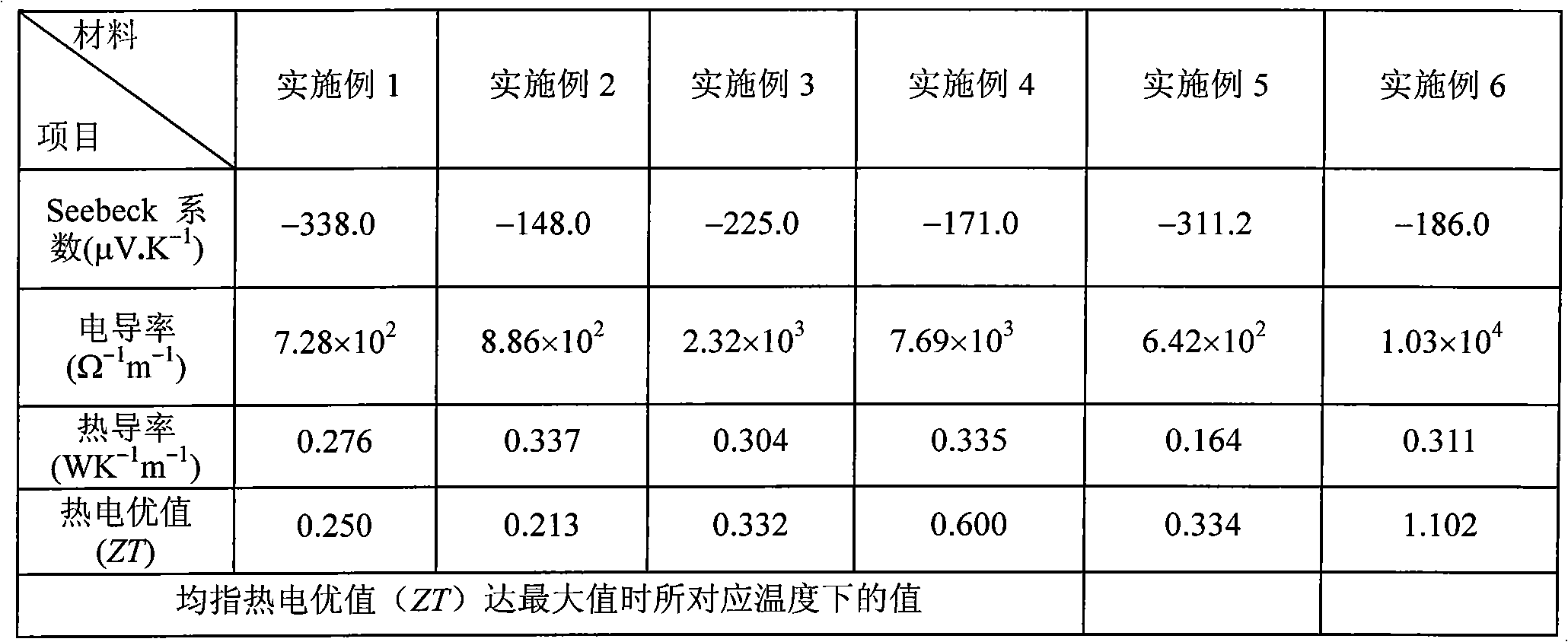

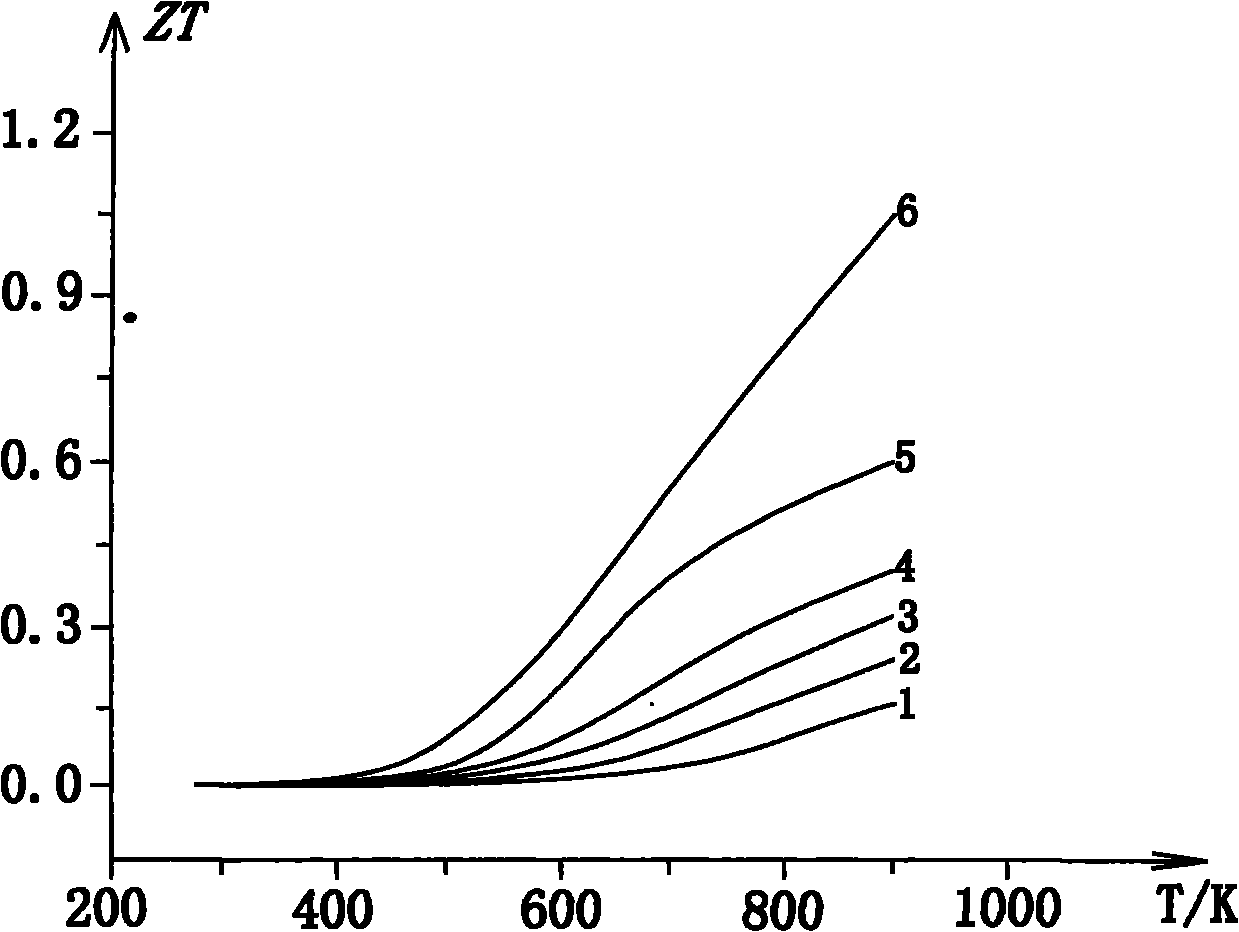

Embodiment 1

[0015] According to the chemical formula In 2 Se 3 The two elements In and Se with a purity greater than 99.999wt.% are weighed and placed in vacuum quartz tubes respectively. The smelting synthesis temperature is 1000-1100° C., and the smelting synthesis time is 24 hours. Shake the tube every 1 hour during the melt to ensure a uniform reaction. After smelting and synthesis, it is slowly cooled to 600-650°C in the furnace, and then quenched in water. The quenched ingot is crushed and ball milled, and the ball milling time is controlled at 5 hours, and the powder after ball milling is formed by discharge plasma spark sintering. The sintering temperature is 550-650° C., the sintering pressure is 40-60 MPa, and the holding time is 8-12 minutes. The sintered bulk material is annealed in a vacuum environment for 20-28 hours, and the annealing temperature is 180-200°C.

Embodiment 2

[0017] The elemental metal Ag with a mole fraction of 0.05 was used to replace In in an equimolar manner. 2 Se 3 In element in. First according to the chemical formula In 1.95 Ag 0.05 Se 3 The three elements In, Ag and Se with a purity greater than 99.999wt.% were weighed and placed in vacuum quartz tubes respectively. The smelting synthesis temperature is 1000-1100° C., and the smelting synthesis time is 24 hours. Shake the tube every 1 hour during the melt to ensure a uniform reaction. After smelting and synthesis, it is slowly cooled to 600-650°C in the furnace, and then quenched in water. The quenched ingot is crushed and ball milled, and the ball milling time is controlled at 5 hours, and the powder after ball milling is formed by discharge plasma spark sintering. The sintering temperature is 550-650° C., the sintering pressure is 40-60 MPa, and the holding time is 8-12 minutes. The sintered bulk material is annealed in a vacuum environment for 20-28 hours, and th...

Embodiment 3

[0019] The elemental metal Ag with a mole fraction of 0.15 was used to replace In in an equimolar manner 2 Se 3 In element in. First according to the chemical formula In 1.85 Ag 0.15 Se 3 The three elements In, Ag and Se with a purity greater than 99.999wt.% were weighed and placed in vacuum quartz tubes respectively. The smelting synthesis temperature is 1000-1100° C., and the smelting synthesis time is 24 hours. Shake the tube every 1 hour during the melt to ensure a uniform reaction. After smelting and synthesis, it is slowly cooled to 600-650°C in the furnace, and then quenched in water. The quenched ingot is crushed and ball milled, and the ball milling time is controlled at 5 hours, and the powder after ball milling is formed by discharge plasma spark sintering. The sintering temperature is 550-650° C., the sintering pressure is 40-60 MPa, and the holding time is 8-12 minutes. The sintered block material is annealed in a vacuum environment for 20-28 hours, and th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com