Natural ventilation air-cooling condenser

An air-cooled condenser and natural ventilation technology, which is applied in the field of heat exchange, can solve difficulties, reduce turbine output, increase air-cooled condenser device support facilities, and install investment to achieve the effect of saving support facilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

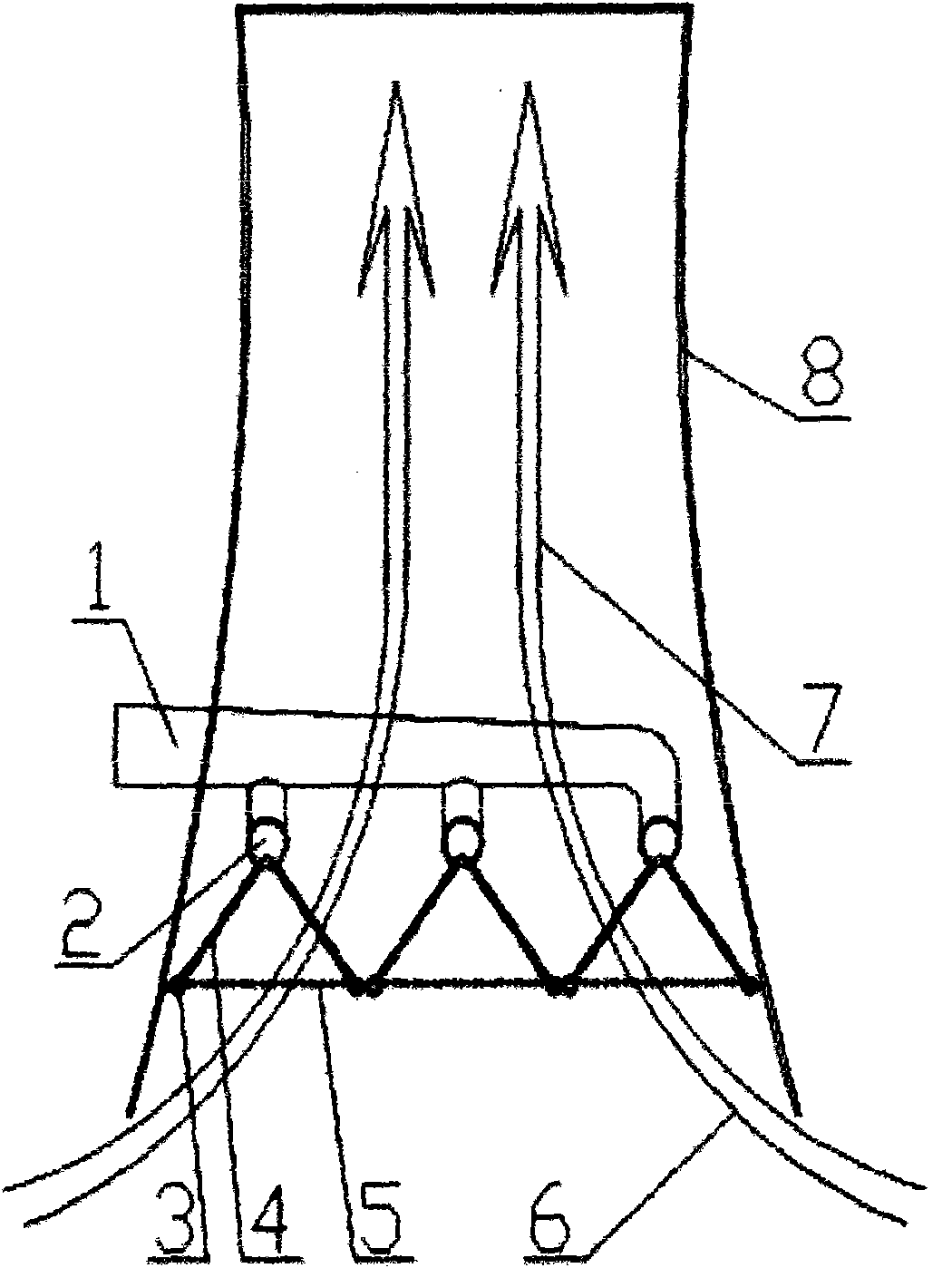

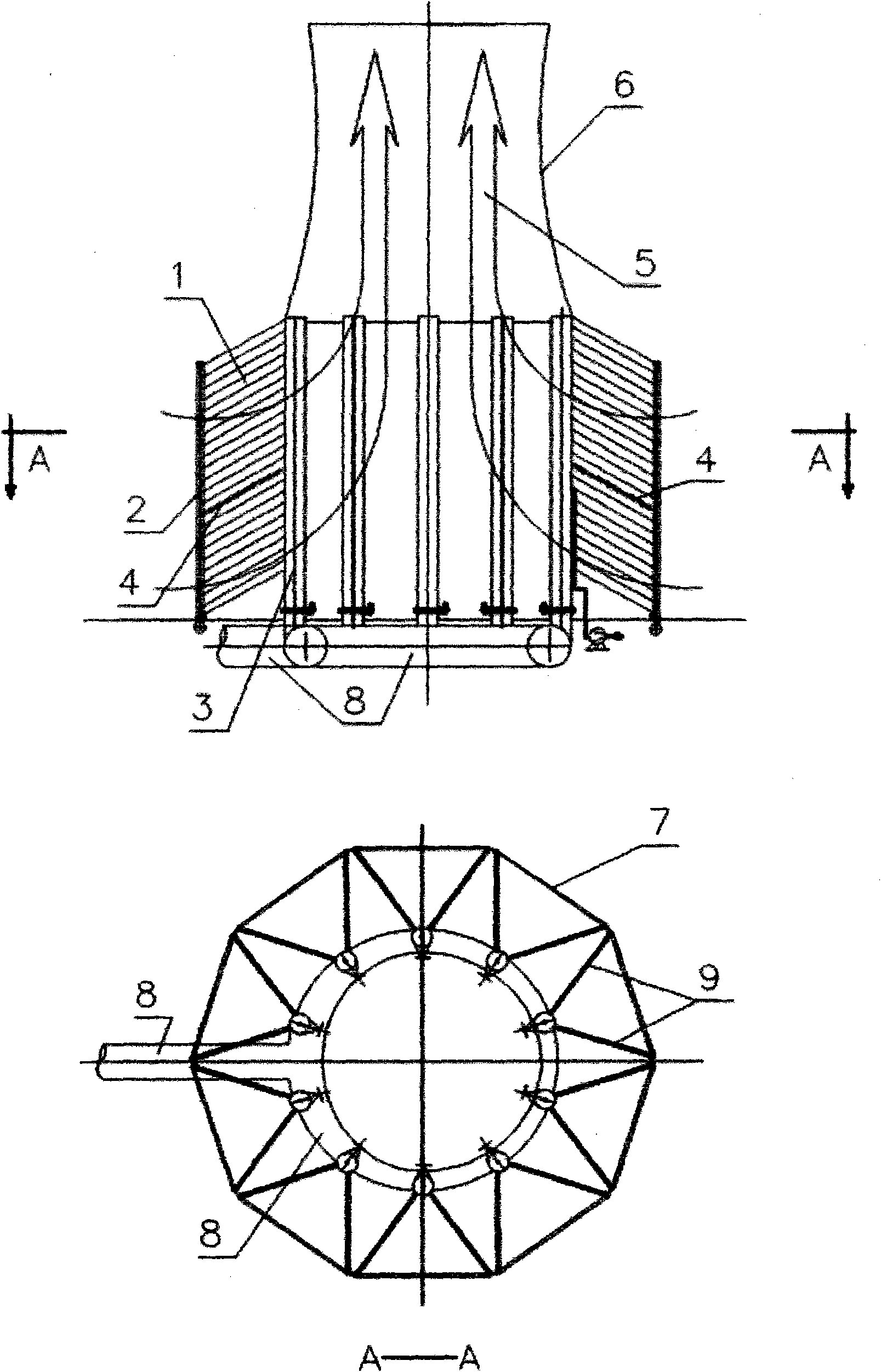

Method used

Image

Examples

Embodiment Construction

[0039] The specific implementation of the present invention will be described below by taking a 600Mw natural draft air-cooled condenser as an example.

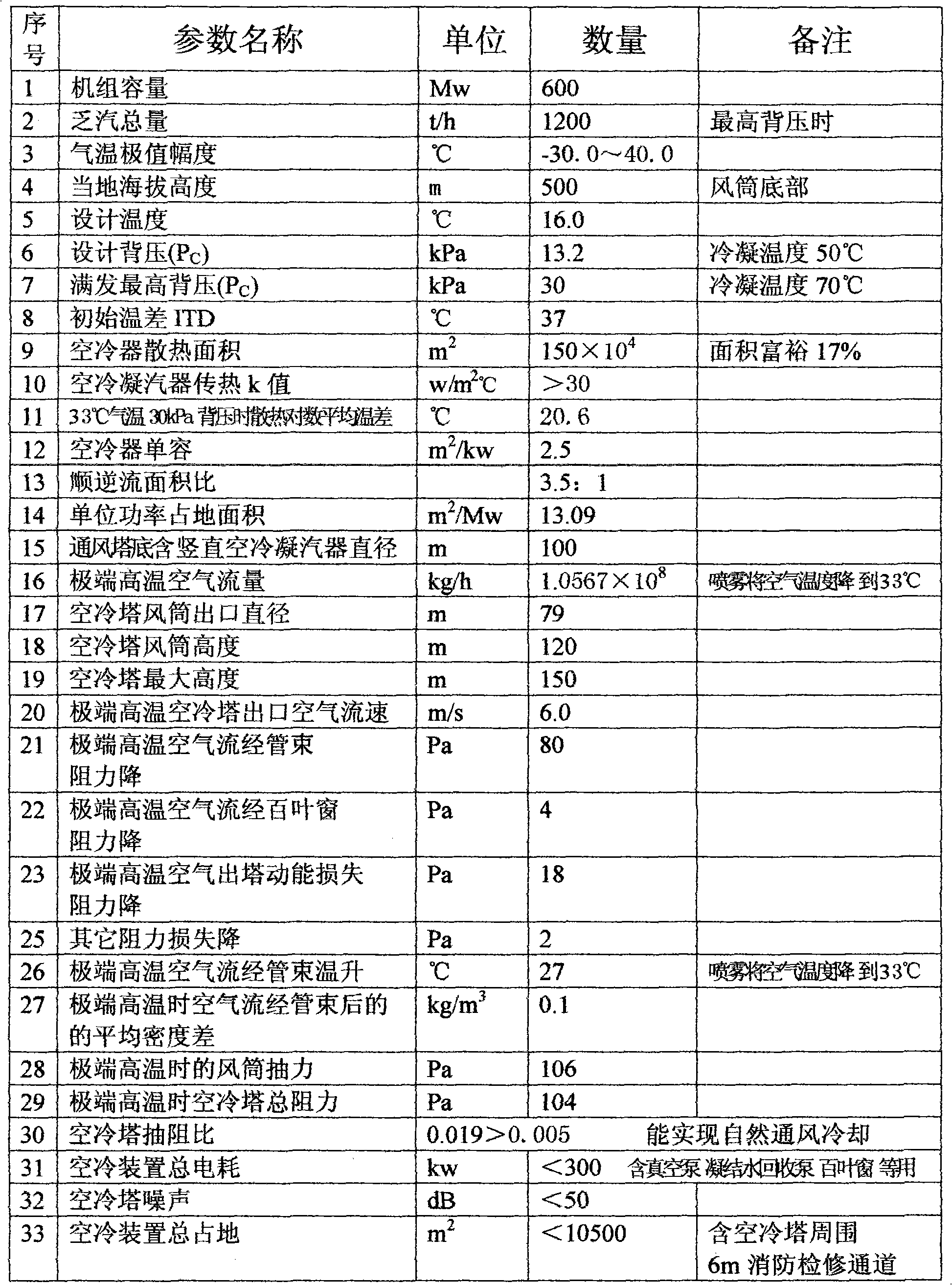

[0040] 1. According to the rated power output of the ultra-supercritical 600Mw unit at a temperature of 33°C in summer, the total amount of exhaust steam is 1200 tons per hour, and the condensing load of the air-cooled condenser is 2.853×10 9 kJ / h, the temperature of the air flowing through the air-cooled condenser rises from 33°C to 60°C, the temperature rise is 27°C, and the required air flow rate is 1.0567×10 8 kg / h, assuming that the flow velocity of the hot air out of the ventilation tower is the maximum 6m / s, and the density of the air at 60°C is 1.0kg / m 3 , the outlet diameter of the ventilation tower is: 79m. The rest of the basic design data are shown in the table below:

[0041]

[0042] The 600Mw large-scale naturally ventilated air-cooled condenser of the power station designed by the present invention can be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com