Dual mesoporous cobalt-based catalyst as well as preparation method and application thereof

A cobalt-based catalyst, double mesoporous technology, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc., can solve problems such as poor connectivity and achieve the effect of avoiding diffusion limitations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

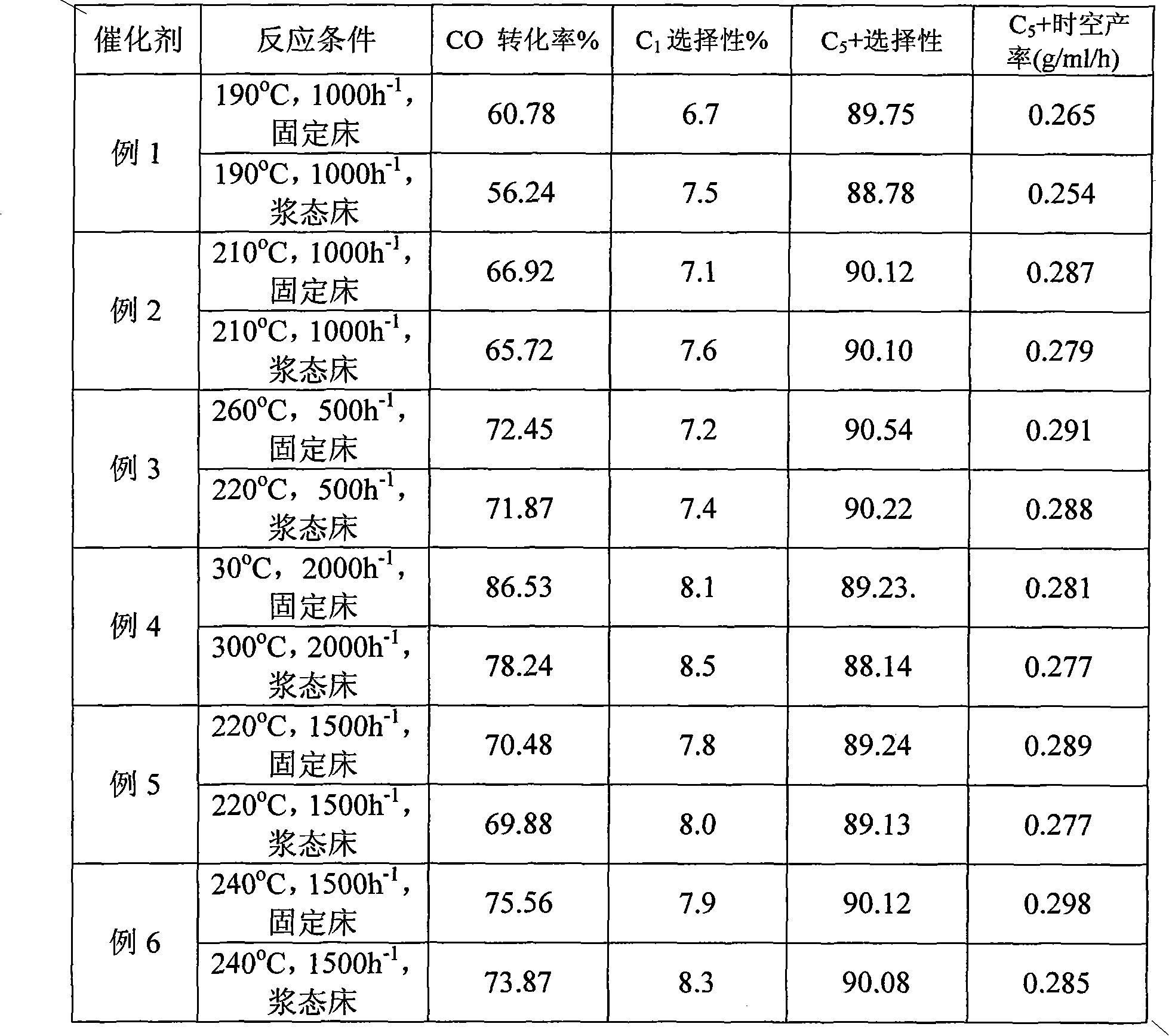

Examples

Embodiment 1

[0021] At 25°C, dissolve 19.6g CTAB in 350ml deionized water, stir for 30min, add 3.22ml TMB, and then add 23.96g Na 2 SiO 3 9H 2 O, continue to stir until the solution is clear, quickly add 35ml of ethyl acetate under stirring, ultrasonic for 60s, stop stirring, let stand for 8h, then age at 60°C for 36h. Finally, after baking at 60° C. for 24 hours, the temperature was raised to 500° C. for 6 hours at 1° C. / min to obtain a double mesoporous carrier.

[0022] 3 g of the support was dissolved in 7.4 ml of a solution containing 2.557 g of cobalt nitrate for equal volume impregnation. Put the undried catalyst sample into the inner layer of a double-layer autoclave connected to the top after impregnating with equal volume for 20 hours, then put 10wt% ammonia solution in the outer layer of the autoclave, seal it and place it in an oven at 60°C for reaction 0.5h, naturally cooled to room temperature, then baked in an oven at 80°C for 12h, and finally baked in a muffle furnace at...

Embodiment 2

[0026] At 30°C, 19.6g CTAB was dissolved in 350ml deionized water, after stirring for 30min, 12.91ml TMB was added, and then 23.96g Na 2 SiO 3 9H 2 O, continue to stir until the solution is clear, quickly add 35ml of ethyl acetate under stirring, ultrasonic for 30s, stop stirring, let stand for 3h, then age at 60°C for 72h. Finally, after baking at 60° C. for 30 h, it was baked at 650° C. for 10 h at 1° C. / min to obtain a double mesoporous carrier.

[0027] 3 g of the support was dissolved in 11 ml of a solution containing 4.719 g of cobalt nitrate for equal volume impregnation. Put the undried catalyst sample into the inner layer of a double-layer autoclave connected to the top after impregnating with equal volume for 20 hours, then put 15wt% ammonia solution in the outer layer of the autoclave, seal it and place it in an oven at 60°C for reaction 1h, naturally cooled to room temperature, then baked in an oven at 60°C for 48h, and finally baked in a muffle furnace at 500°C...

Embodiment 3

[0031] At 40°C, 19.6g CTAB was dissolved in 350ml deionized water, after stirring for 40min, 18.21ml TMB was added, and then 23.96g Na 2 SiO 3 9H 2 O, continue to stir until the solution is clear, add 35ml of ethyl acetate quickly under stirring, ultrasonic for 40s, stop stirring, let stand for 8h, and then age at 90°C for 48h. Finally, after baking at 60° C. for 30 h, it was baked at 500° C. for 8 h at 1° C. / min to obtain a double mesoporous carrier.

[0032] 3 g of the support was dissolved in 6.8 ml of a solution containing 1.754 g of cobalt nitrate for equal volume impregnation. Put the undried catalyst sample into the inner layer of a double-layer autoclave connected to the top after impregnating equal volume for 25 hours, then put 20wt% ammonia solution in the outer layer of the autoclave, seal it and place it in an oven at 80°C for reaction 1h, naturally cooled to room temperature, then baked in an oven at 60°C for 24h, and finally baked in a muffle furnace at 500°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com