Yeast wastewater treatment method, feed additive obtained by same and feed product

A feed additive, organic wastewater treatment technology, applied in food industry wastewater treatment, water/sewage treatment, heating water/sewage treatment, etc., can solve the problems of unreported and unreported potassium content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

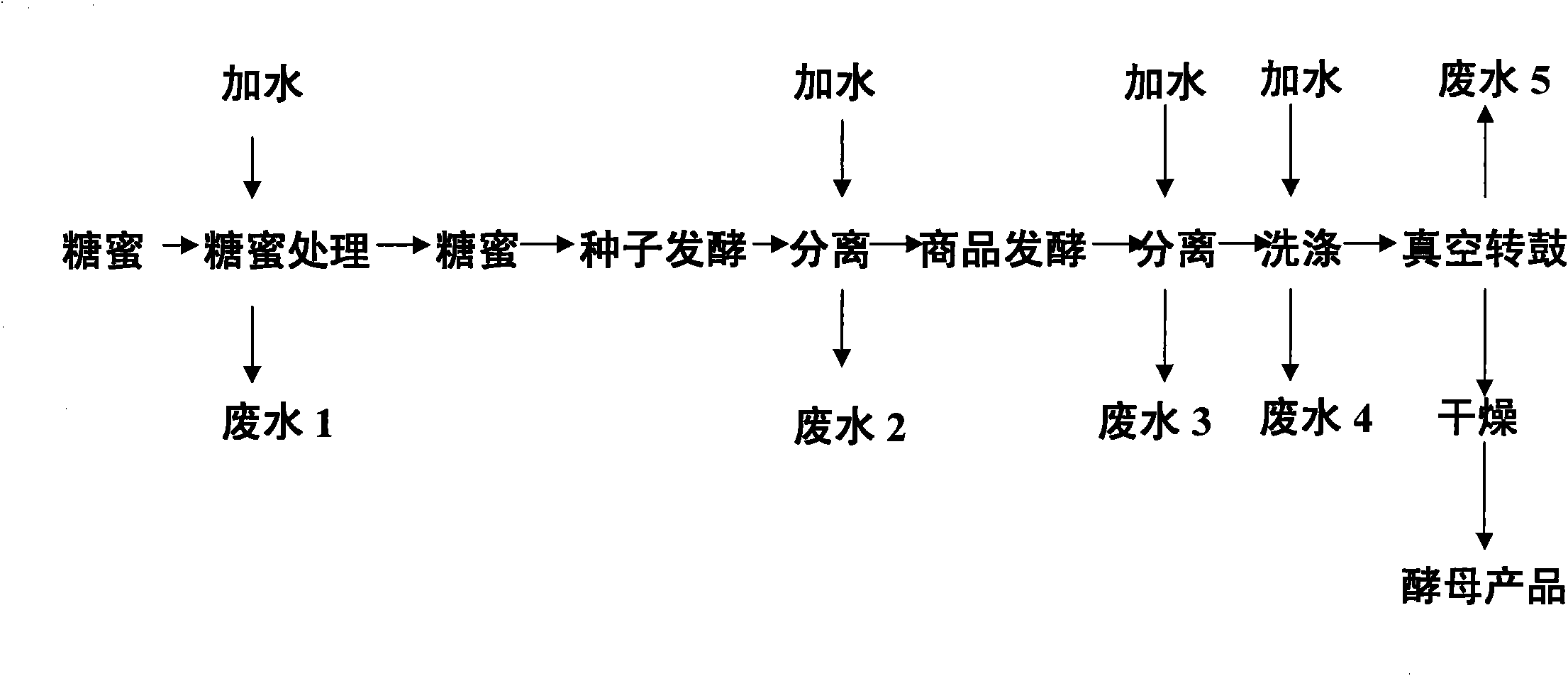

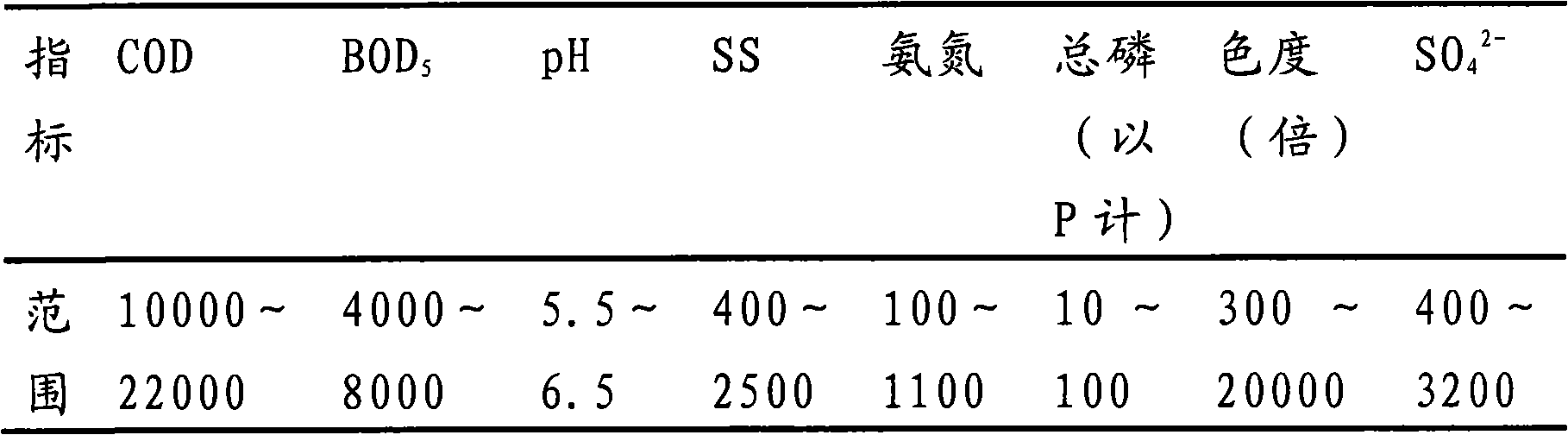

[0066] Embodiment 1 yeast high-concentration organic wastewater treatment process

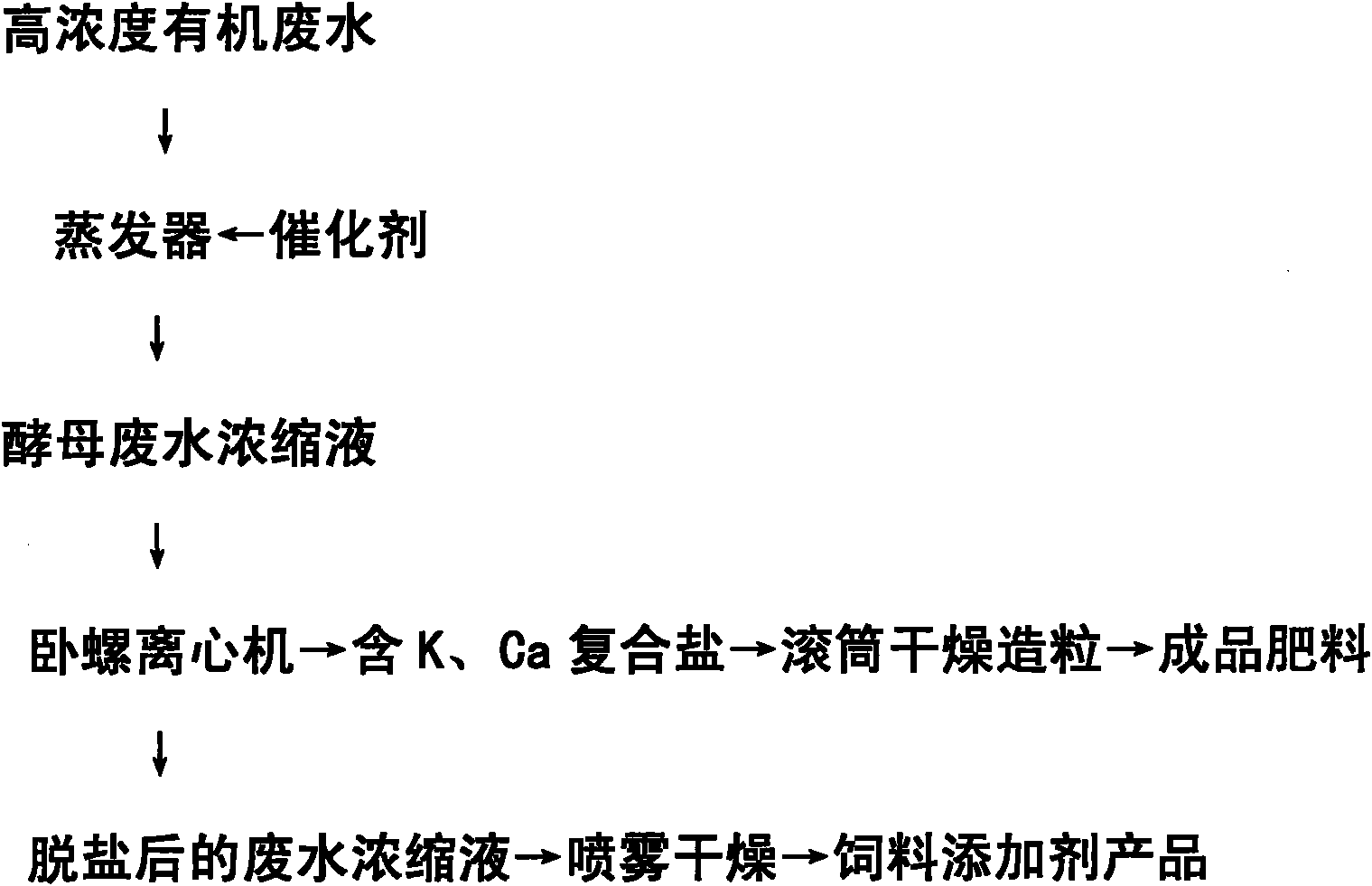

[0067] according to figure 2 The illustrated process flow for treating high-concentration yeast organic wastewater is for treating high-concentration yeast organic wastewater.

[0068] Specifically, beet molasses was used as raw material to ferment Saccharomyces cerevisiae, and the high-concentration organic wastewater produced by the yeast during the fermentation and separation process was added to a six-effect falling film evaporator (manufacturer: Yixing Grant), and the high-concentration organic wastewater was evenly distributed through the distribution device. Distributed in each effect heater of the evaporator. Under the action of gravity, vacuum induction and air flow, the material flows from top to bottom in the form of a film. During the movement, it exchanges heat with the steam heated on the outer wall of the heater and evaporates. Gas-liquid separation, the upper layer pumps out the...

Embodiment 2

[0094] Embodiment 2 Another kind of yeast high-concentration organic wastewater treatment process

[0095] according to figure 2 The illustrated process flow for treating high-concentration yeast organic wastewater is for treating high-concentration yeast organic wastewater.

[0096] Specifically, beet molasses was used as raw material to ferment Saccharomyces cerevisiae, and the high-concentration organic wastewater produced by the yeast during the fermentation and separation process was added to a six-effect falling film evaporator (manufacturer: Yixing Grant), and the high-concentration organic wastewater was evenly distributed through the distribution device. Distributed in the heater of the evaporator, the material flows from top to bottom in the form of a film under the action of gravity, vacuum induction and air flow. During the movement, it exchanges heat with the steam heated on the outer wall of the heater and evaporates, and then the gas enters the separation chamb...

Embodiment 3

[0121] Embodiment 3 Contains the preparation of the feed of the feed additive that is made by yeast high-concentration organic wastewater concentrate

[0122] The feed additive of embodiment 1 or 2 gained is directly added in the corresponding full-price compound feed product according to the additive dosage described in following table 5, as adding the feed additive of 1.5% (w / w) in the poultry compound feed, then using The feed mixer was mixed for 10 minutes to ensure that the product was evenly mixed in the feed. The mixed product can be directly fed to poultry animals.

[0123] Table 5 Recommended dosage of feed additives made from yeast high-concentration organic wastewater concentrate in various feeds

[0124]

PUM

| Property | Measurement | Unit |

|---|---|---|

| chemical oxygen demand (mass) | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com