Ecological dust suppressant for surface mine dust treatment and preparation method thereof

A dust suppressant and ecological technology, which is applied in the field of ecological dust suppressant for dust control in open-pit mines and its preparation, can solve the problems of unfriendly environment, achieve the effects of improving affinity, improving dust suppression effect, and reducing water loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

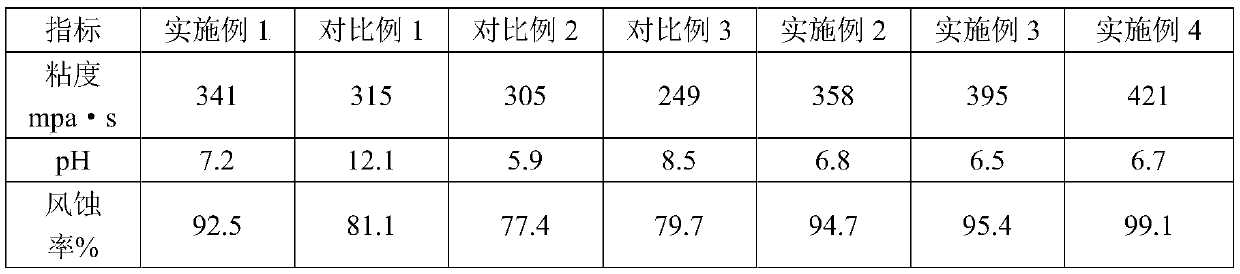

Examples

Embodiment 1

[0031] An ecological dust suppressant, the content of each component:

[0033] Sodium dodecylbenzenesulfonate: 1%

[0034] Sodium polyacrylate: 2%

[0035] Glycerol: 2%

[0036] Sodium Lactate: 1.75%

[0037] Water: 88.25%.

[0038] 1) Add 2030g of water into the reactor, start stirring, and add 115g of sodium silicate;

[0039] 2) Slowly raise the temperature to 35°C, add 46g of sodium polyacrylate to make a sodium polyacrylate solution, and stir to dissolve;

[0040] 3) Add 46g of glycerol, 40.3g of sodium lactate, and 23g of sodium dodecylbenzenesulfonate in sequence, and stir the solution evenly;

[0041] 4) Add citric acid again, stir for 30 minutes at a rotating speed of 400r / min, the pH is measured to be 7.2, and the dust suppressant is obtained.

[0042] Dilute the dust suppressant by 5 times in proportion, and then spray it on the surface of the tailings or dump site, the spraying amount per unit area is 1.5kg / m 2 After the mound w...

Embodiment 2

[0053] An ecological dust suppressant, the content of each component:

[0054] Urea: 3.45%

[0055] Fatty alcohol polyoxyethylene ether: 3.45%

[0056] Sodium polyacrylate: 1.725%

[0057] Glycerol: 3%

[0058] Sodium Lactate: 1.725%

[0059] Water: 86.66%.

[0060] 1) Add 2009g of water into the reactor, start stirring, and add 80g of urea;

[0061] 2) Slowly raise the temperature to 40°C, add 40g of sodium polyacrylate to make a sodium polyacrylate solution, and stir to dissolve;

[0062] 3) Add 70g of glycerol, 40g of sodium lactate, and 80g of fatty alcohol polyoxyethylene ether in sequence, and stir the solution evenly;

[0063] 4) Add an appropriate amount of citric acid, stir for 30 minutes under a mixer with a rotating speed of 400r / min, and stir evenly. The optimum pH is measured as 6.8, and the dust suppressant is obtained.

[0064] Dilute the dust suppressant by 3 times in proportion, and then spray it on the surface of the tailings or dump site, the spraying a...

Embodiment 3

[0066] An ecological dust suppressant, the content of each component:

[0067] Sodium silicate: 9.80%

[0068] Tween 60: 3.52%

[0069] Sodium polyacrylate: 4.70%

[0070] Glycerol: 1.57%

[0071] Sodium Lactate: 1.57%

[0072] Water: 78.84%;

[0073] 1) Add 2011g of water into the reactor, start stirring, and add 250g of sodium silicate;

[0074] 2) Slowly raise the temperature to 40°C, add 120g of sodium polyacrylate to make a sodium polyacrylate solution, and stir to dissolve;

[0075] 3) Add 40g glycerol, 40g sodium lactate, and 90g Tween 60 in sequence, and stir the solution evenly;

[0076] 4) Add an appropriate amount of citric acid, stir for 50 minutes under a mixer with a rotating speed of 300r / min, stir evenly, and measure the pH to be 6.5 to obtain a dust suppressant.

[0077] Dilute the dust suppressant by 8 times in proportion, and then spray it on the surface of the tailings or dump site, the spraying amount per unit area is 1.5kg / m 2 After the mound was ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com