Retarding cement slurry composite for replacement of super-deep freezing hole and preparation method thereof

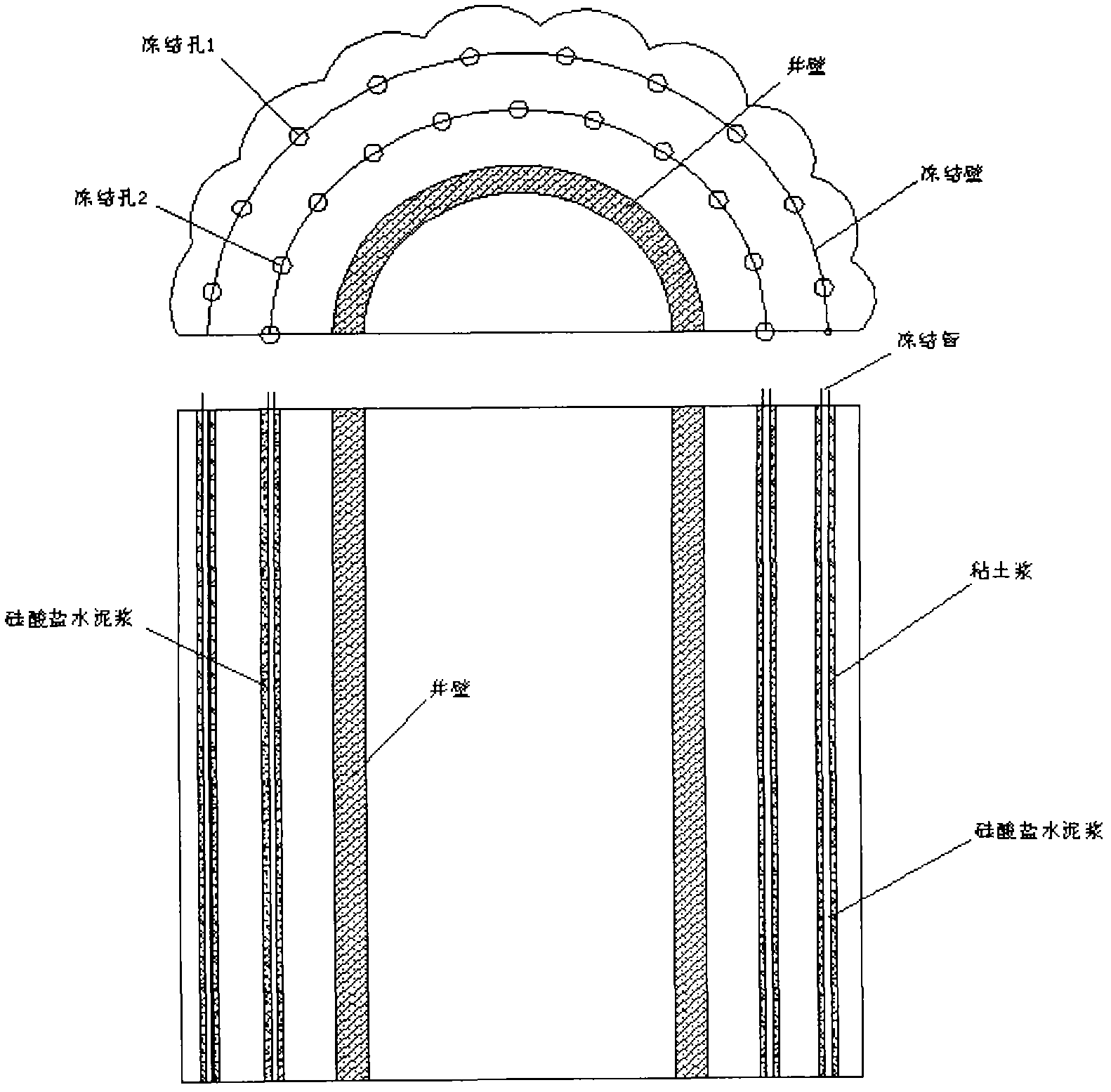

A technology of cement slurry and composition, which is applied in the field of slow-setting cement slurry composition for replacement of ultra-deep frozen holes, which can solve the problems of prolonging the well construction period, pouring into the bottom of the well, and flooding the well due to water inrush, and achieves good replaceability , slurry stability, long retarding time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

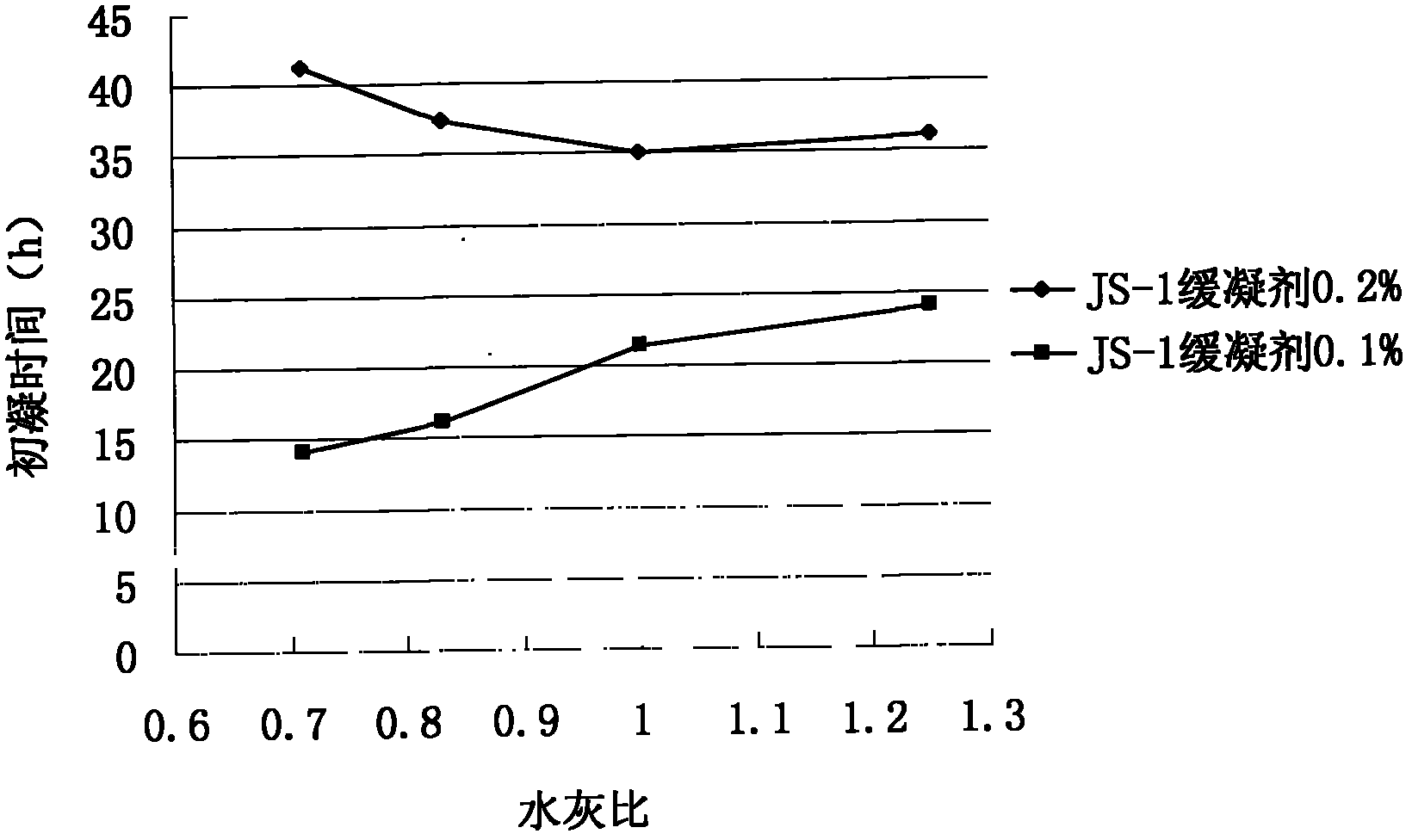

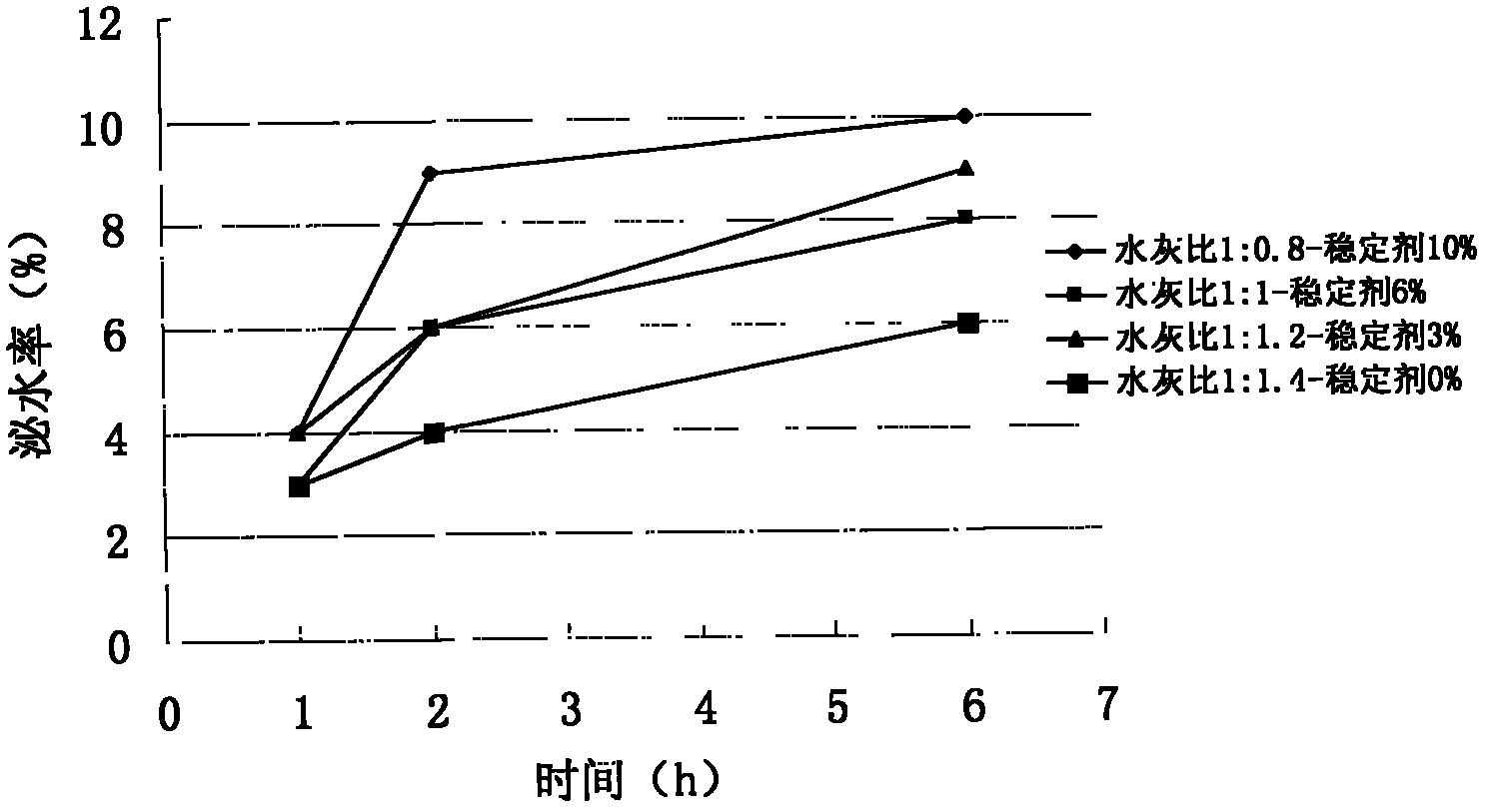

[0024] A retarded cement slurry composition for ultra-deep frozen hole replacement, the composition is composed of Portland cement, retarded water reducer, stabilizer, water, the composition is composed of Portland cement, retarded water reducer , stabilizer, water composition, by mass ratio by water: cement=1 part: 0.7 part~1 part: 1.5 part is prepared into retarded portland cement slurry, wherein the added retarded water reducer should account for 0.1 of cement mass to 0.3 parts, the added stabilizer should account for 0 to 10 parts of the cement mass, and the stabilizer is bentonite.

[0025] The retarding superplasticizer is a JS-1 type retarder, and the JS-1 type retarder is composed of hydroxycarboxylic acid and its inorganic salts, and the hydroxycarboxylic acid is citric acid or tartaric acid One or two are added at the same time. The inorganic salts are one of sulfate and borate, or two are added at the same time. According to the mass ratio, hydroxycarboxylic acids a...

Embodiment 2

[0033] A retarded cement slurry composition for replacing ultra-deep frozen holes, prepared from water: cement = 1 part: 0.8 part to 1 part: 1.4 parts by mass ratio to prepare retarded portland cement slurry, wherein the added retarded The water agent should account for 0.2 to 0.25 parts of the cement mass, and the added stabilizer should account for 2 to 8 parts of the cement mass. The preparation method is the same as in Example 1.

Embodiment 3

[0035] A retarded cement slurry composition for replacement of ultra-deep frozen holes, prepared from water: cement = 1 part: 1.5 parts by mass ratio to prepare retarded Portland cement slurry, wherein the added retarded water reducer should account for the mass of cement 0.3 part, the stabilizing agent that adds should account for 10 parts of cement quality, and described stabilizing agent is bentonite, and preparation method is with embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com