Double hydraulic straw methane pool for self-circulation medium temperature two-step fermentation and forced discharging method

A two-step method and fermentation tank technology, applied in waste fuels, biochemical equipment and methods, gas production bioreactors, etc., can solve problems such as increased carbon emissions, messy biogas residues, straw fly dust pollution aversion, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

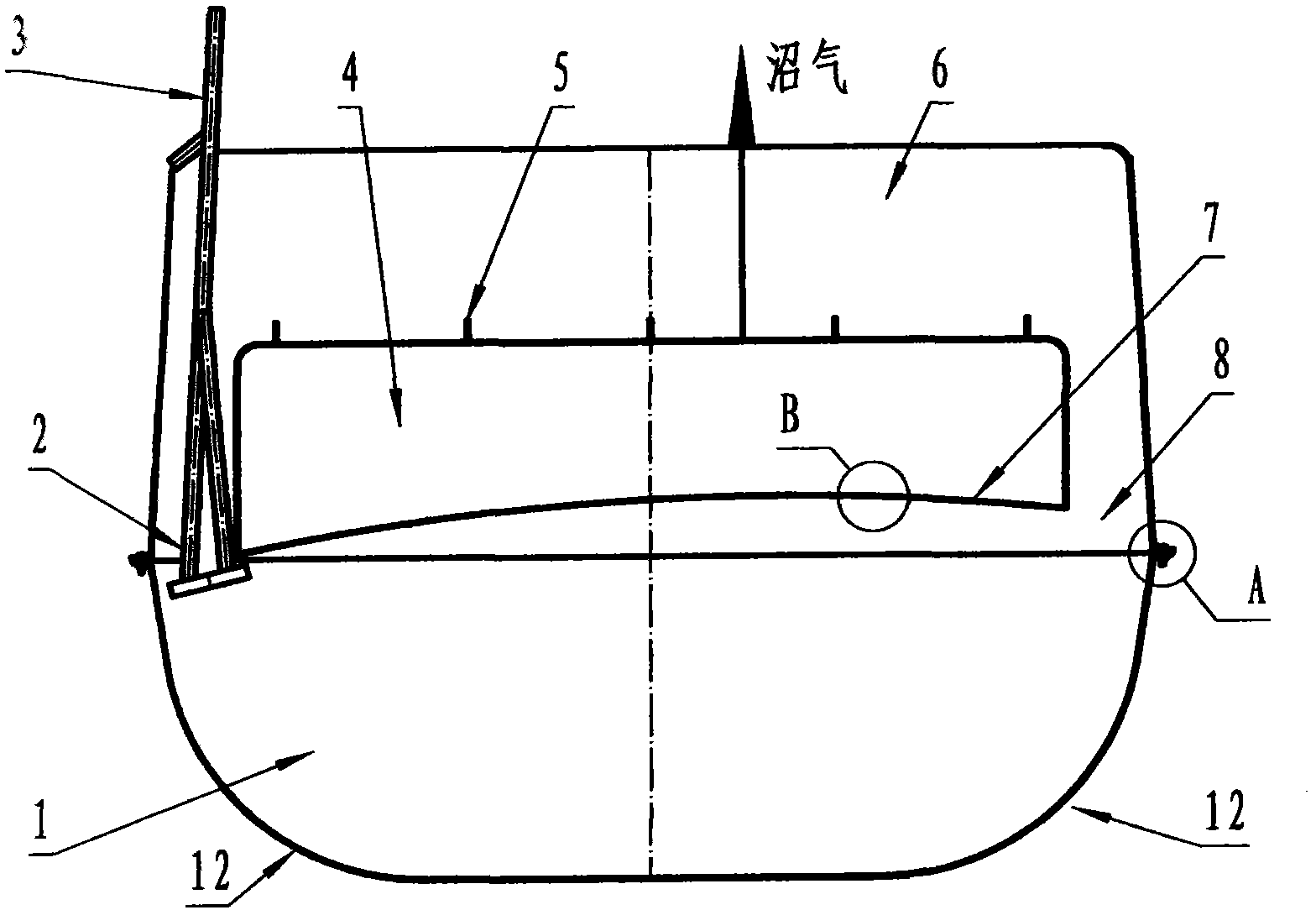

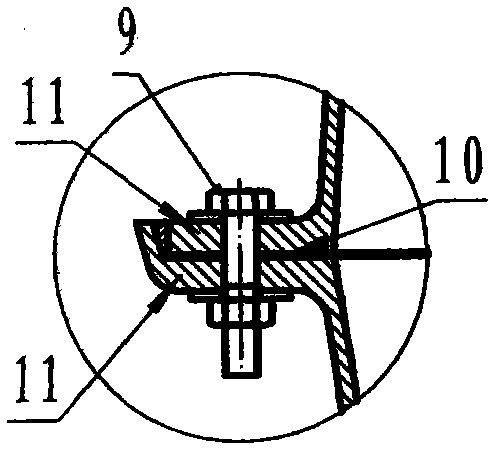

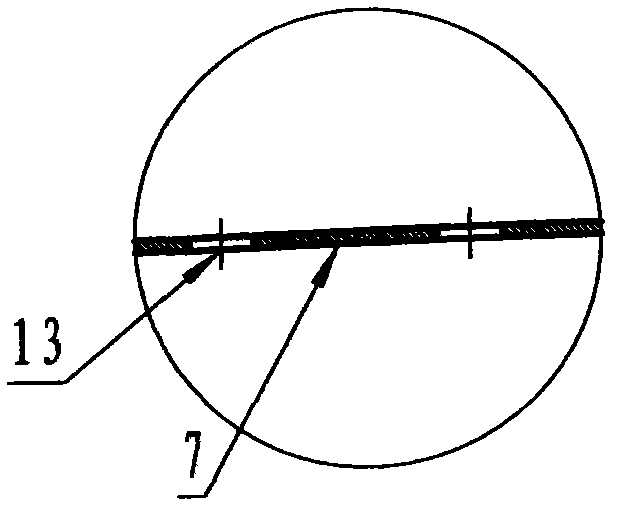

[0016] figure 1 It is an embodiment of the present invention: a double-hydraulic pressure straw biogas digester for self-circulation medium-temperature two-step fermentation, consisting of a fermentation tank (1), a feed port (2), and a discharge port (8), and is characterized in that: The cuboid fermenter (1) with large rounded corners (12) at the bottom is fastened with a water pressure room (6) with an upper opening, and the bolt (9), sealing material (10) and Respective flanges (11) seal the fermentation tank (1) and the water pressure room (6) into a rectangular pool body with an upper opening and place it on the ground. The lower part of the room (6) separates out, there is a spacing of 20cm between the left and right vertical walls of the gas storage chamber (4) and the left and right vertical walls of the water pressure room (6), and thus the spacing is on the left side It constitutes the feed port (2), and the right side constitutes the discharge port (8), and in thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com