Titanium anode plate with precious metal combination coating

A coating and inner coating technology, applied in the direction of electrodes, electrolysis components, electrolysis process, etc., can solve the problems of short service life of anode, failure to solve, corrosion of anode material, etc., to extend service life, reduce cell voltage, improve Yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

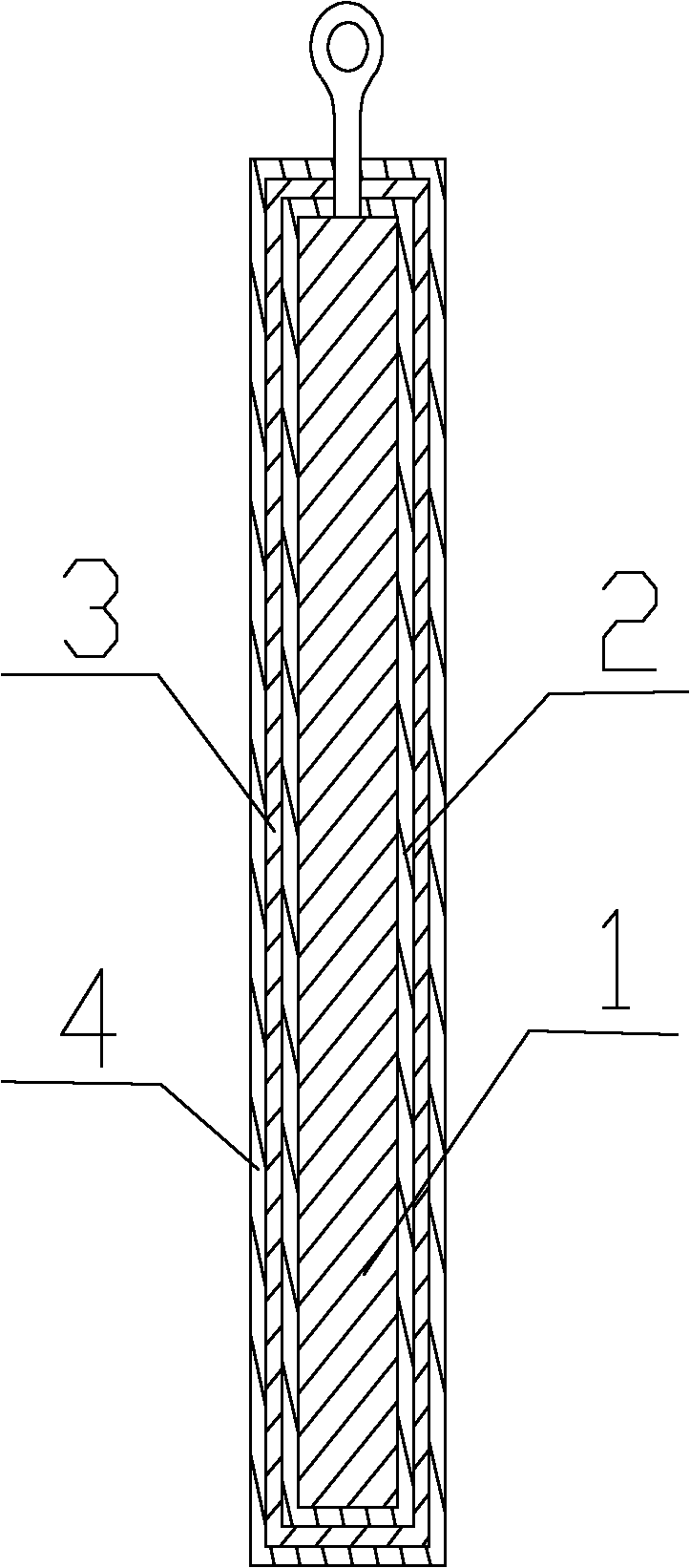

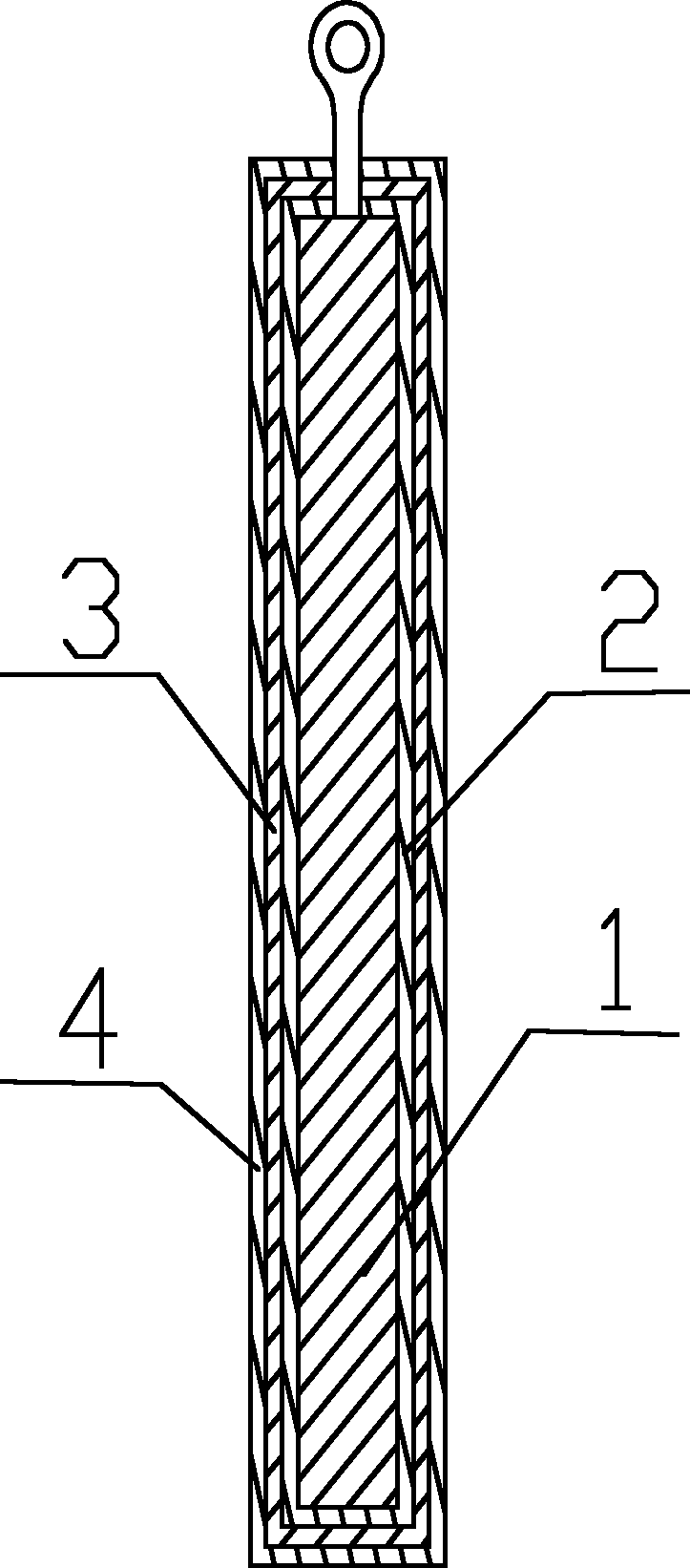

[0009] Attached below figure 1 An embodiment of the present invention is described.

[0010] A titanium anode plate with a noble metal composite coating, has a titanium substrate 1, the surface of the titanium substrate 1 is coated with a ruthenium oxide coating, a mixed coating of molybdenum oxide, tantalum oxide and titanium oxide, and an iridium oxide coating. Oxide and palladium oxide mixed coating. The ruthenium oxide RuO2 is mixed with the binder and painted on the surface of the titanium substrate 1 to form an inner coating 2, and the molybdenum oxide MoO3, tantalum oxide Ta2O5 and titanium oxide TiO2 are mixed with the binder and painted on the surface of the titanium base material 1. An intermediate coating 3 is formed on the surface of the inner coating 2 , and the surface of the intermediate coating 3 is brushed after mixing iridium oxide IrO2 and palladium oxide PdO with a binder to form an outer coating 4 . The thicknesses of the inner coating 2 , the intermedia...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com