Easy cation-dyeable polyester (ECDP) fibers and production method thereof

A polyester fiber and cationic technology, applied in normal pressure cationic dyeable polyester fiber and its production field, can solve the problems of unobvious practical value, cationic fiber dyeing conditions of high temperature and high pressure, and the inability to mix natural fibers such as wool

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

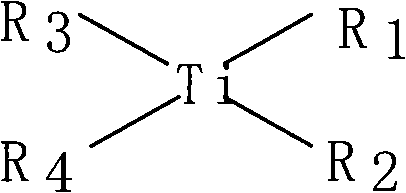

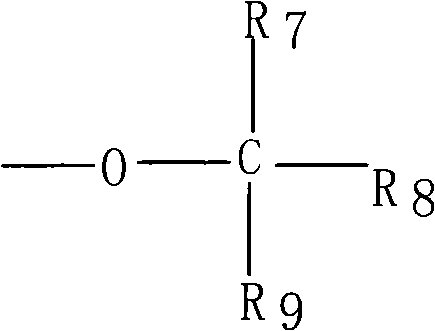

Method used

Image

Examples

Embodiment 1

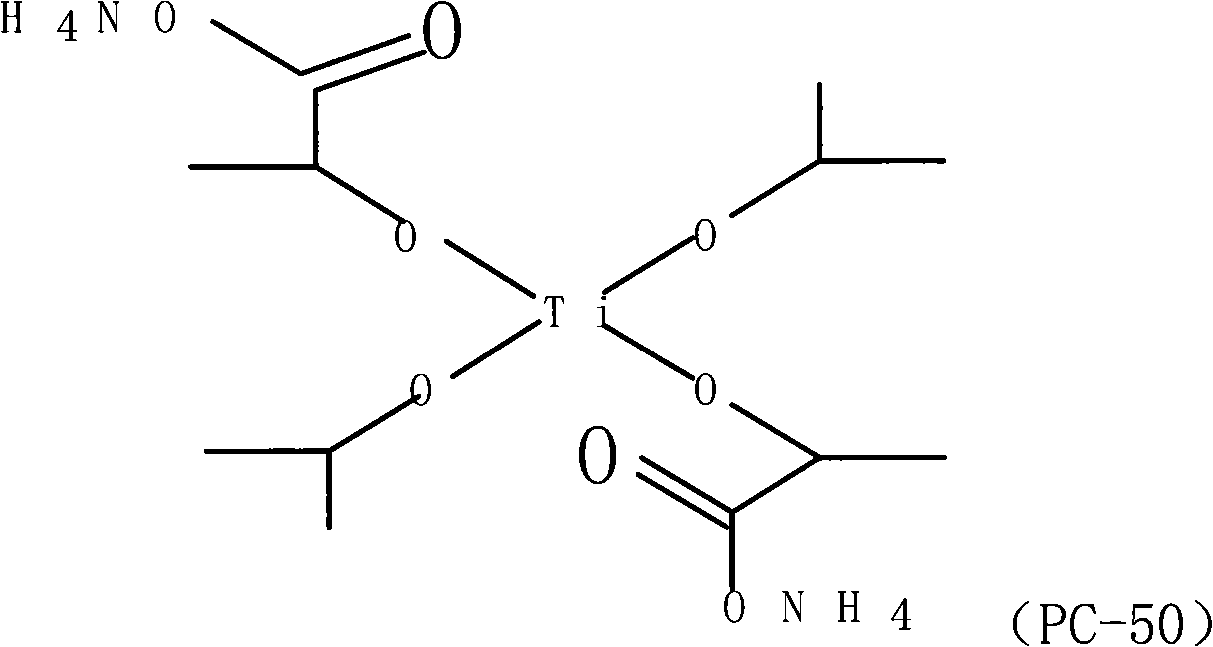

[0045] The polyethylene glycol molecular weight is 1000, the addition amount is 1wt%, the amount of isophthalic acid-5-sodium sulfonate (SSIA) is 0.9wt%, and is produced by PC-50 as a catalyst, and the intrinsic viscosity is 0.62dl / g atmospheric pressure cationic dyeable polyester chips are dried to below 100ppm, the chips enter the screw through the silo and melt at a temperature of 290°C, the discharge volume is controlled by the metering pump, and the temperature is controlled by the spinning box at 290°C Spinning assembly in the lower part, spun nascent fibers, cooled and solidified under the condition of side blowing wind speed 20m / min, and then oiled the fibers evenly through the oiling nozzle to bundle the fibers and reduce friction, the oiling rate was 0.9%. The fibers that have been oiled and bundled pass through the spinning shaft and enter the first roller (1GR) at a speed of 1500m / min, and then enter the coiler for coiling after passing through the second roller (2...

Embodiment 2

[0048] The polyethylene glycol molecular weight is 4000, the addition amount is 1wt%, isophthalic acid-5-sodium sulfonate (SSIA) is 3.7wt%, and is produced by PC-50 as a catalyst, and the intrinsic viscosity is 0.65dl / g normal pressure cationic dyeable polyester chip is dried to below 100ppm, carries out spinning stretch processing with embodiment 1, under the condition that elongation ratio is 2.12, makes elongation reach 38.2%, strength reaches 2.97cN / dtex, the strength and elongation product reaches 18.4, the monofilament fineness is 1.75dtex, and the boiling water shrinkage rate is 7.6%. It is a cationic dyeable polyester fiber under normal pressure. The fabric made of this fiber uses cationic blue dye with a concentration of 5%. After dyeing under normal pressure below 100°C, the dye uptake rate reaches over 90%, and its hue L value is below 25; using cationic blue dye, the concentration 0.3%, after dyeing at normal pressure below 100°C, its light resistance can reach l...

Embodiment 3

[0050] The polyethylene glycol molecular weight is 1000, the addition amount is 4wt%, isophthalic acid-5-sodium sulfonate (SSIA) is 3.7wt%, and is produced by PC-50 as a catalyst, and the intrinsic viscosity is 0.60dl / g normal pressure cationic dyeable polyester chips are dried to below 100ppm, and the same as in Example 1 is carried out for spinning and stretching. Under the condition of elongation ratio of 2.23, the obtained elongation reaches 40.6%, and the strength reaches 2.90cN / g. Atmospheric pressure cationic dyeable polyester fiber with dtex, strength and elongation product up to 18.5, monofilament fineness of 0.5dtex, boiling water shrinkage rate of 5.1%. The fabric made of this fiber uses cationic blue dye with a concentration of 5%. After dyeing under normal pressure below 100°C, the dye uptake rate reaches over 90%, and its hue L value is below 25; using cationic blue dye, the concentration 0.3%, after dyeing at normal pressure below 100°C, its light resistance ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Intrinsic viscosity | aaaaa | aaaaa |

| Strength | aaaaa | aaaaa |

| Monofilament denier | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com