Solar battery component cover plate glass and solar battery component

A solar cell and cover glass technology, applied in the field of solar cells, can solve problems such as increased difficulty in solar energy, complex molds, and weak bonding, and achieve the effects of easy promotion and application, simple manufacturing process, and low battery leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

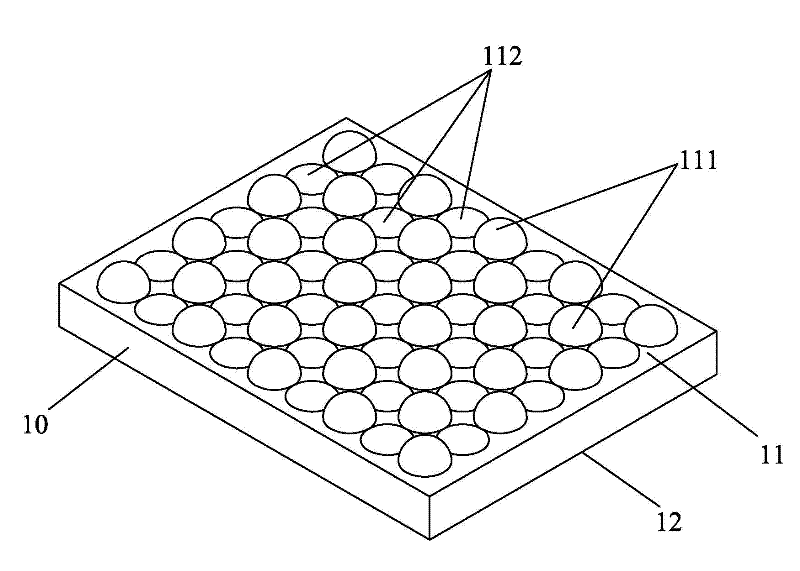

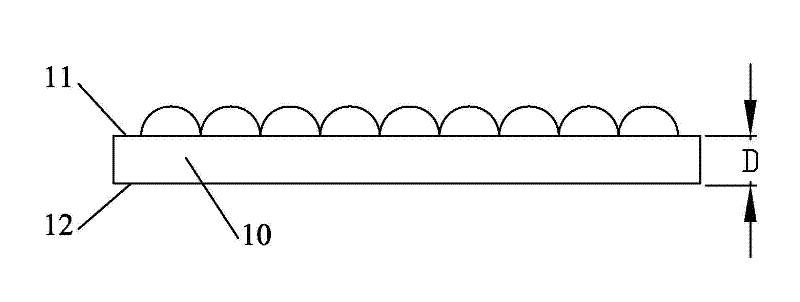

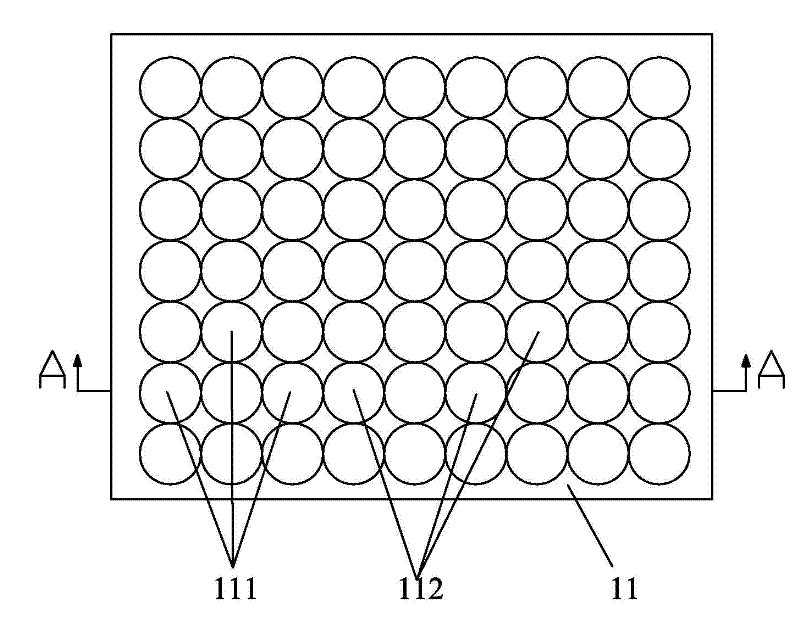

[0034] One of the specific implementations of a solar cell module cover glass of the present invention, such as figure 1 , figure 2 , image 3 and Figure 4As shown, a glass substrate 10 is included, wherein the glass substrate 10 has a first surface 11 and a second surface 12, the first surface 11 is arranged on the side facing the incident sunlight, and the second surface 12 is arranged on the side facing the solar cell module On one side of the EVA layer of the silicon wafer, the first surface 11 is provided with a pattern structure having hemispherical unit protrusions 111 and hemispherical unit depressions 112, and the second surface 12 is a suede structure. Wherein, the hemispherical unit depression 112 is a hemispherical hole surface. Specifically, the pattern structure is a pattern structure composed of hemispherical unit protrusions 111 and hemispherical unit depressions 112 arranged horizontally and vertically. Next to a hemispherical unit protrusion 111, so tha...

Embodiment 2

[0040] The second specific embodiment of a solar cell module cover glass of the present invention, such as Figure 5 and Figure 6 As shown, the main technical solution of this embodiment is the same as that of Embodiment 1, and the features not explained in this embodiment adopt the explanation in Embodiment 1, and will not be repeated here, and are described in Figure 5 and Figure 6 neutralize figure 1 , figure 2 , image 3 and Figure 4 The same parts bear the same reference numerals. The difference between this embodiment and Embodiment 1 is that the pattern structure is a pattern structure composed of hemispherical unit protrusions 111 and hemispherical unit recesses 112 arranged at intervals in the horizontal and vertical directions. That is, in the transverse direction, there is a certain distance between a hemispherical unit protrusion 111 and a hemispherical unit depression 112, and there is a certain distance between a hemispherical unit depression 112 and a...

Embodiment 3

[0042] The third specific embodiment of a solar cell module cover glass of the present invention, the main technical solution of this embodiment is the same as that of embodiment 1, and the features not explained in this embodiment are explained in embodiment 1, and are described in This will not be repeated here. The difference between this embodiment and Embodiment 1 is that the radius R of the hemispherical unit protrusion 111 is 0.5 mm˜1.9 mm, and the radius R of the hemispherical unit recess 112 is 0.5 mm˜1.9 mm.

[0043] Wherein, the radius R of the hemispherical unit protrusion 111 can be 0.5mm, 1.9mm, 1.7mm or 1mm, and the radius R of the hemispherical unit depression 112 can be 0.5mm, 1.9mm, 1.7mm or 1mm.

[0044] In addition, the hemispherical unit protrusion 111 and the hemispherical unit recess 112 may have the same radius length or different radius lengths.

[0045] Wherein, the thickness D of the glass substrate 10 may be 5.1 mm, 5.7 mm or 5.4 mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com