Method for manufacturing high-temperature resistant transparent electric heating film

A production method, electric heating film technology, applied in the direction of electric heating devices, ohmic resistance heating, electrical components, etc., can solve the problems of fast decay of electric heating film at high temperature, affect practicability, and not resistant to dry burning, etc., and achieve slow decay and use temperature range Wide, the effect of ensuring the stability of the film resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] A method for manufacturing a high-temperature-resistant transparent electrothermal film of the present invention is to select an insulating substrate, modify the surface of the substrate, make electrodes on the surface of the electrothermal film, and age the electrothermal film. The specific process is: preparing a surface modification solution, purifying the substrate materials, surface modification, making electrodes, energized aging,

[0046] 1. Preparation of Surface Modification Solution

[0047] (1) The formula component weight ratio (unit: gram) is:

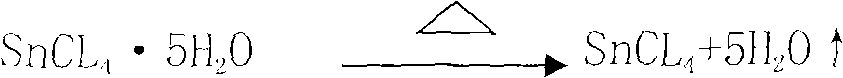

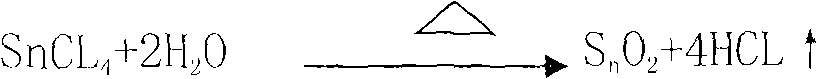

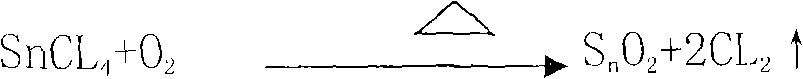

[0048] Tin tetrachloride (SnCl 4 ·5H 2 O) 300...Main ingredients

[0049] Ruthenium trichloride (RuCl 3 ) 3...high temperature resistance stabilizer

[0050] Bismuth Hydroxide (Bi(OH) 3 ) 4...high temperature resistance stabilizer

[0051] Barium titanate (BaTiO 3 ) 5... High voltage resistance stabilizer

[0052] Fluoboric acid (HBF 4 ) 2... dopant

[0053] Proper amount of hydrofluoric acid (HF)...doping ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com