Process for efficiently recovering afterheat generated in the process of producing sulfuric acid from pyritic

A pyrite, waste heat technology, used in preheating, chemical industry, sulfur compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

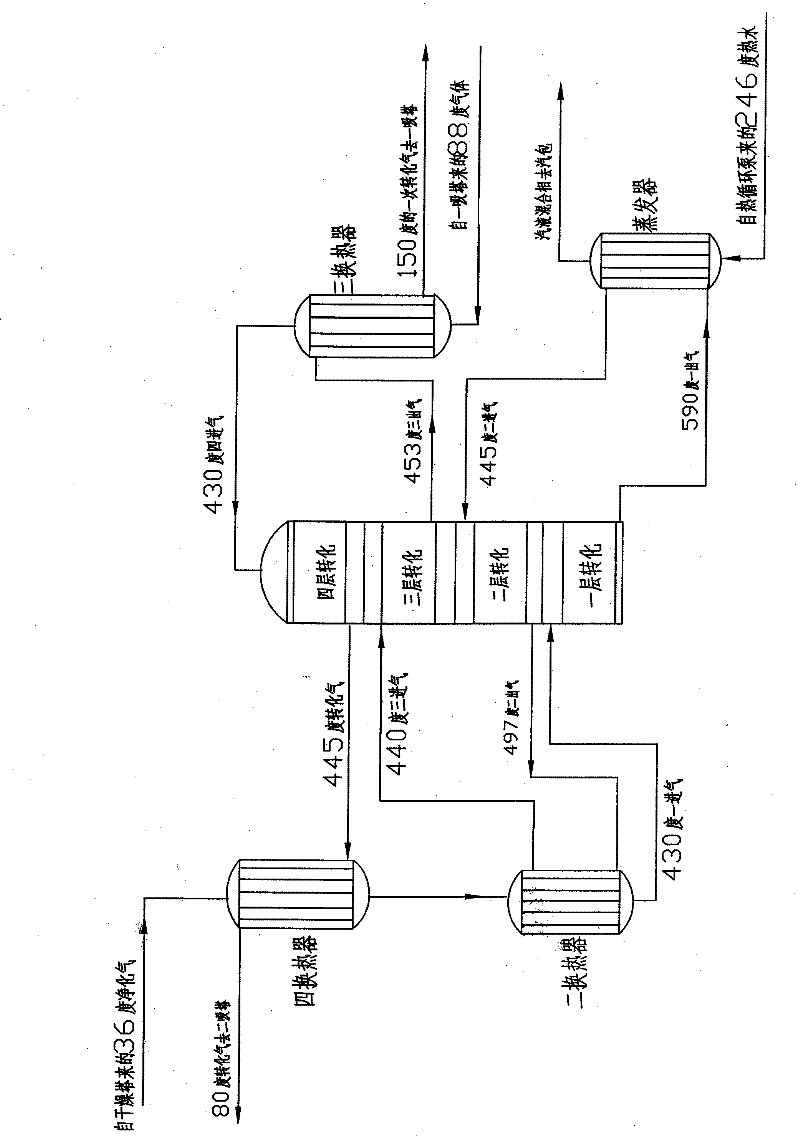

[0147] Take the sulfuric acid production line with an annual output of 300,000 tons of Hunan Xinhengguang Technology Co., Ltd. as an example.

[0148] The production of sulfuric acid is 37.5 tons per hour. The conversion gas concentration is 8.3%, and the 3+1 process of two rotations and two suctions is adopted.

[0149] 1. The temperature of the raw material gas coming out of the fluidized fluidized furnace is 980°C, the temperature drops to 350°C through the waste heat boiler, and then enters the electric dust collector through the cyclone separator.

[0150] 2. The temperature of the electrostatic precipitator is about 320°C, and the gas volume is 74330Nm 3 / h, the heat brought by the raw material gas is about 10.68*10 6 kcal / h, the moisture content of the raw material gas is generally 6.0% (volume content), the temperature drops to 100°C after passing through the three-chamber heat storage heat exchanger, and the air temperature in front of the furnace is 280°C. Process...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com